WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

DOING continuous automatic waste tyre oil plant has many advantages, such as 24 hours continuous work, high oil yield, good safety, intelligent automatic control, labor cost&energy saving, environment friendly, etc.

At present, how to effectively and environmentally friendly working with a pyrolysis plant is a hot topic. More and more customers are applying for DOING latest design fully automatic continuous pyrolysis plant to process waste tires and plastic to obtain fuel oil. Why is DOING continuous automatic waste tyre oil plant getting so popular? Here let's see the advantages of DOING continuous automatic waste tyre oil plant.

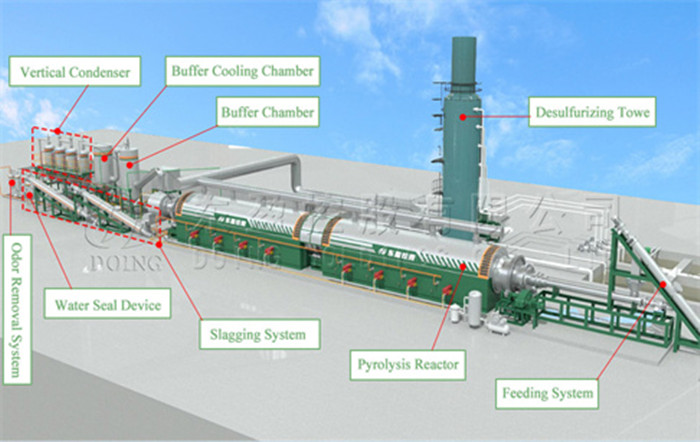

DOING new design fully continuous waste tyres pyrolysis plant

DOING new design fully continuous waste tyres pyrolysis plant

1.24 hours of continuous work, high pyrolysis efficiency

DOING continuous automatic waste tyre oil plant can keep working 24 hours a day. It adopts the fully automatic screw-sealed feeding and discharging system, which can ensure high pyrolysis efficiency and high production capacity.

In the whole pyrolysis process, the feeding speed of the feeder can be set to control the whole process in an orderly manner. The slag can be discharged without waiting for the reactor to cool.

The details of fully continuous pyrolysis plant

The details of fully continuous pyrolysis plant

2. Good safety, high oil yield, long service life

The pyrolysis reactor is the core part of the continuous automatic waste tyre oil plant. The pyrolysis reactor is divided into two parts, and the reactor is driven by three groups of tugs to rotate at a constant speed to achieve uniform heating. Waste tyres can be fully cracked without coking, with high oil yield and good fuel quality.

And the connection of the pyrolysis reactor is equipped with a cooling device to ensure safety. The interior of the pyrolysis reactor adopts the indirect heating method of the internal combustion chamber, and the hot air generated by the combustion is used to heat the inner furnace to avoid direct contact between the inner furnace and the flame, which can prolong the equipment service life.

Good safety, high oil yield, long service life

Good safety, high oil yield, long service life

3. Intelligent automatic control, safety and environmental protection, saving labor costs

The continuous automatic waste tyre oil plant can be intelligently controlled by PLC system, and the production line has a high degree of automation, saving labor investment costs. For each single equipment and control point, it can achieve real-time monitoring, display, calculation, and corresponding instructions can be issued. It truly realizes intelligent and safe operation.

4.Low processing cost and energy saving

Apart from the final products like fuel oil, carbon black, steel wire, you can also obtain some syn-gas and use it as a fuel for heating, saving energy and reducing emissions; the material cooling adopts the indirect cooling method of circulating water, which is not only pollution-free, but also low in consumption. The entire continuous automatic waste tyre oil plant has a simple process flow, and the treatment cost is much lower than other waste treatment methods.

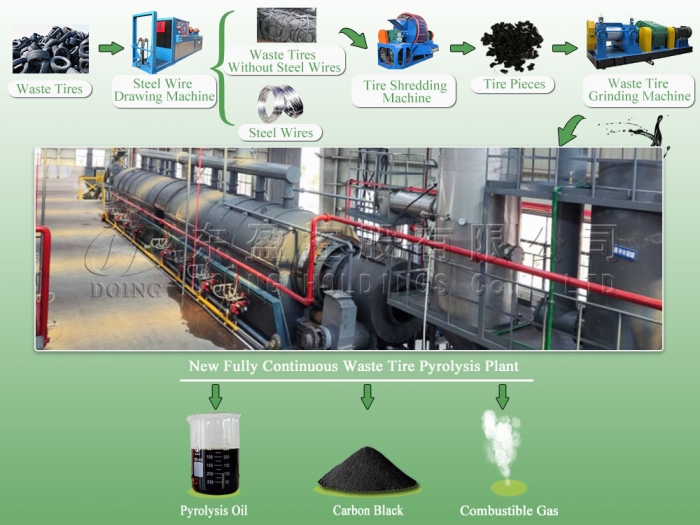

The products of fully continuous pyrolysis plant

The products of fully continuous pyrolysis plant

5.Good environmental benefits

DOING continuous automatic waste tyre oil plant is designed to be safe and environmentally friendly. The whole process of pyrolysis is completed in a closed equipment reactor, which avoids the problem of dust and VOC leakage and does not produce secondary pollution. And the equipment is equipped with a flue gas purification system, and the exhaust gas emission meets the EU emission standards.

With the above advantages, Henan Doing Company's continuous automatic waste tyre oil plant has become the first choice for many customers to purchase continuous pyrolysis plants. For more information, please feel free to contact us, our team of engineers and project managers will customize the best waste tyre pyrolysis solution for you.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.