| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

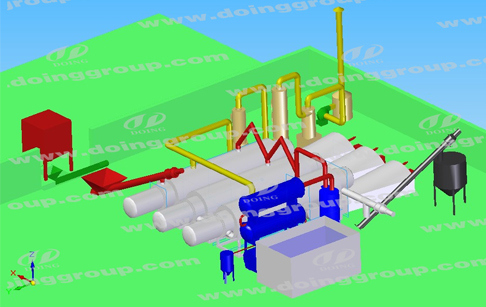

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

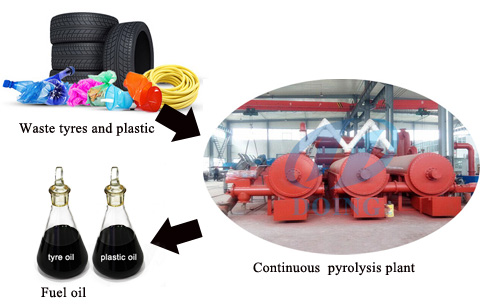

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

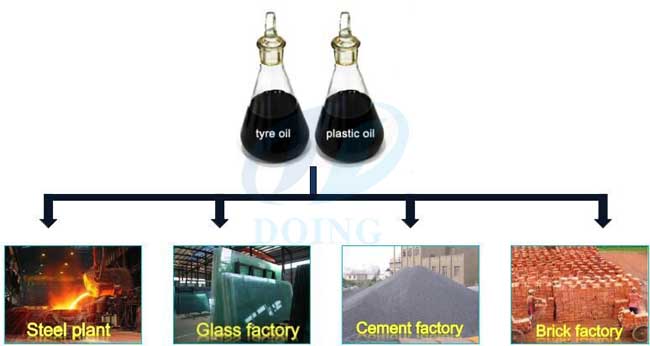

| NO | Name | Percentage | Usage |

| 1 | Tire /plasticoil | 45% |

1.Can be sold directly 2.Can be as fuel 3.Can be used industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic factory. |

| 2 | Carbon black | 30% |

1.Can be sold directly 2.Can be used electric cable jacketing,black nylon bag,rubber additive |

| 3 | Steel wire | 15% |

1.Can be sold directly 2.Make steel bloom by use hydraulic press-packing |

| 4 | Oil gas | 10% |

1.Can be as fuel burn by use gas burning system 2.Extra gas also be storage as fuel for other heating |