WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

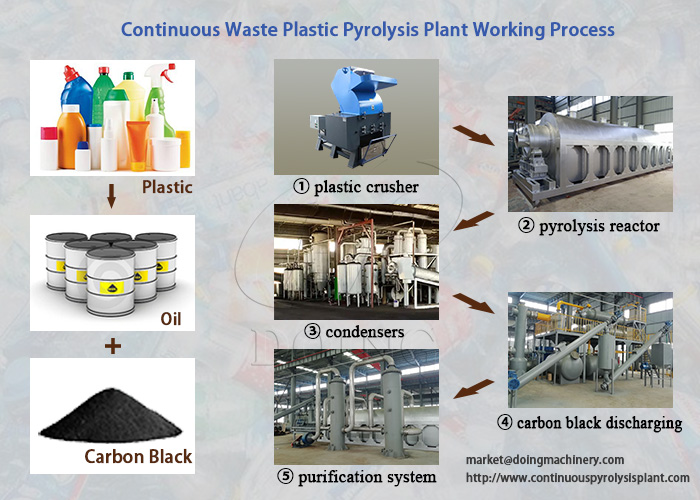

When you are ready to start the waste aluminum and plastic pyrolysis business, choosing a good quality waste aluminum and plastic pyrolysis machine should be the first step you consider. Adhering to the concept of "Quality First, Integrity First", Doing has made a series of breakthroughs in the equipment and technology of waste aluminum and plastic pyrolysis to help you reduce costs and obtain more profits. Now let us take a look at the advantages of Doing's waste aluminum and plastic pyrolysis machine.

Doing's waste aluminum and plastic pyrolysis machines

Doing's waste aluminum and plastic pyrolysis machines

1. Security

The core main furnace reactor for heating waste aluminum and plastics, Doing adopts a standard arc-shaped pressure head design, which can bear high temperature and high pressure, one-piece pressing, and is not easy to crack. The machine is equipped with safety devices such as thermometers, pressure gauges, safety valves, water seals and vacuum devices to ensure the operating conditions of the equipment at any time.

2. Environmental protection

Doing's waste aluminum and plastic pyrolysis machine is equipped with environmental protection devices, exhaust gas purification systems and desulfurization towers. The flue gas generated during the heating process of the reactor enters the desulfurization tower for purification treatment, which meets the national environmental protection emission standard, and can achieve zero emission of exhaust gas. The whole process is well sealed to prevent dust pollution.

3. Energy saving

After the non-condensable combustible gas is processed by the tail gas purification system, it can be used as fuel for heating the reactor, which greatly saves production fuel and costs.

4. High degree of automation

Waste aluminum and plastic pyrolysis plant with PLC control system

Doing's continuous waste aluminum and plastic pyrolysis machine adopts PLC control system, automatic feeding and automatic slag discharge, which saves time and manpower, and is convenient for control and operation. The next round of production can be carried out without waiting for the reactor to cool, which improves production efficiency.

Pyrolysis plant with PLC control system

Pyrolysis plant with PLC control system

5. High oil yield

Condensation of oil and gas into oil is a key step in determining the oil yield. Doing sets up vertical condensers and horizontal condensers in order in the cooling stage, using the most commonly used and most effective condensers in the oil pyrolysis industry to ensure the oil gas are fully cooled and the oil output rate is high.

Doing's waste aluminum and plastic pyrolysis machine has all the above advantages. The company has been engaged in waste tires, plastics, oil sludge and aluminum and plastic pyrolysis for more than ten years. It has an independent technical research and development team, the production process is mature. If you want to use waste aluminum and plastic to get oil, it is better to act now!

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.