WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

According to the analysis of tire composition, it is mainly composed of rubber, carbon black, steel wire, sulfur zinc oxide and sulfur additives and other auxiliary materials, the main component is rubber. As we all know, rubber is actually a petroleum product, so we can get oil by processing waste tires.

There are two main ways to produce oil from waste tires, one is direct combustion and the other is by high temperature pyrolysis through the waste tire pyrolysis plant. However direct combustion is not only ineffective to get oil but also causes great pollution to the environment. While high temperature pyrolysis is a method that uses pyrolysis chemical reaction to crack waste tyres into oil and gas in a closed, anaerobic and high temperature environment, and further cool to obtain fuel oil, carbon black, and steel wire. The whole process of high temperature pyrolysis not only can obtain pyrolysis oil but also will not cause pollution to the environment, which is the easiest and most environmentally friendly way to produce pyrolysis oil from waste tires.

Waste tires to pyrolysis oil

Waste tires to pyrolysis oil

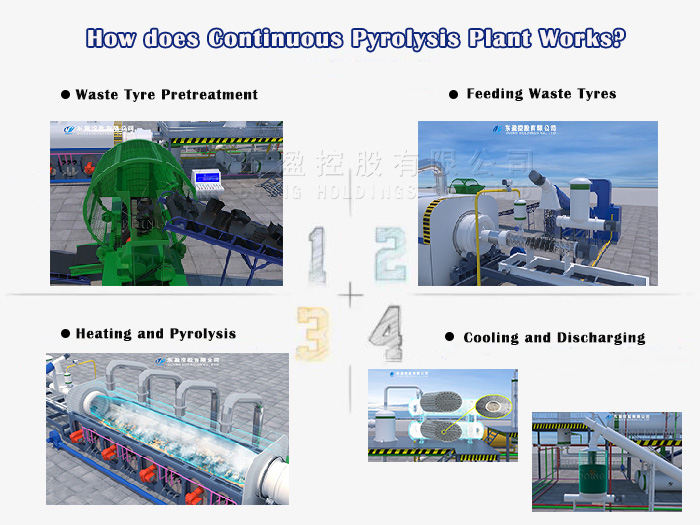

After knowing that the waste tire pyrolysis plant can turn waste tires into pyrolysis oil, you may also want to know how the waste tire pyrolysis plant works, let us take a closer look.

From waste tires to pyrolysis oil, it is necessary to go through tire pretreatment, continuous pyrolysis, cooling, tail gas purification, discharge carbon black and fume treatment these steps. Next, Henan Doing company will give you a detailed introduction, please continue reading.

The working flow of waste tire pyrolysis plant

The working flow of waste tire pyrolysis plant

1、Tire pre-treatment

Use a wire drawing machine to pull out the steel wire from the tire, and use a feeder cage to seal and transport the waste tire to the reactor.

2、Continuous pyrolysis

The rubber powder transported to the reactor is cracked under high temperature and oxygen-free conditions, and generates oil and gas after reaching a certain temperature.

3、Cooling

The generated oil and gas are buffered by the buffer tank and then enter the condensing system for cooling. Pass through the buffer condensate tank, vertical condenser and horizontal condenser in turn to condense the oil and gas into oil

4、Tail gas purification

After passing through the condensing system, the remaining non-condensable combustible gas is processed by the tail gas purification system and used as fuel for heating the cracking reactor.

5、Discharge carbon black

Drain the carbon black from the reactor with a carbon black twisting cage

6、Fume treatment

After the flue gas generated during the heating process of the reactor enters the desulfurization tower for purification treatment, it reaches the national environmental protection emission standard and is discharged into the atmosphere.

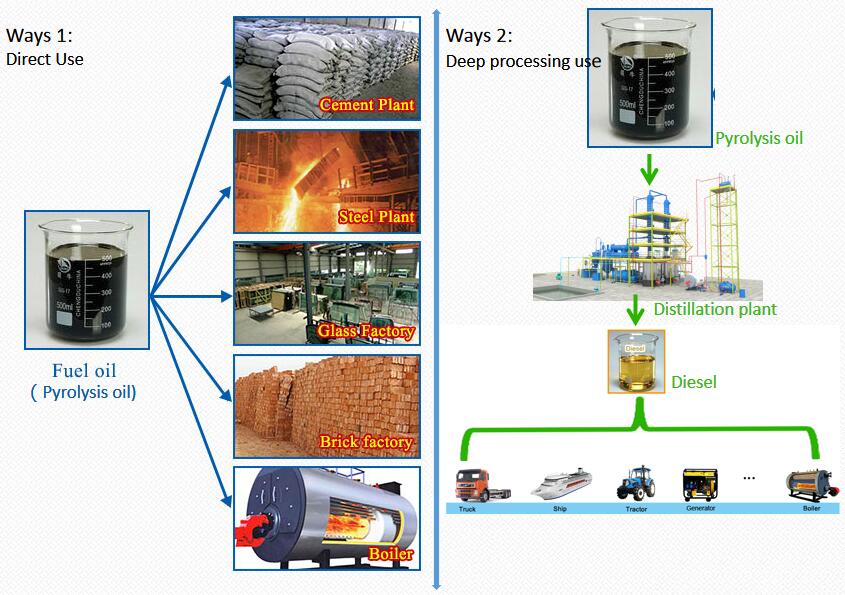

The pyrolysis oil produced by the above operations is a new type of energy and has a wide range of uses. The pyrolysis oil recovered from tires is mainly used as fuel for industrial combustion. It can be sold to boilers, cement factories, brick factories, glass factories, steel factories and other factories that need fuel. In addition, the pyrolysis oil recovered from tires can also be used in waste oil distillation machine to refine the pyrolysis oil into clean and transparent non-standard diesel, which can be used in diesel generators, heavy machinery, and can also be sold as light fuel.

The uses of pyrolysis oil

The uses of pyrolysis oil

If you want to pyrolyze waste tires into oil, you can consider this easiest and environmentally friendly method. Doing company can provide you with equipment. Our waste tire pyrolysis plant has high oil yield, high safety factor and strong environmental performance, for more details of the equipment, you can contact us at any time.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.