WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

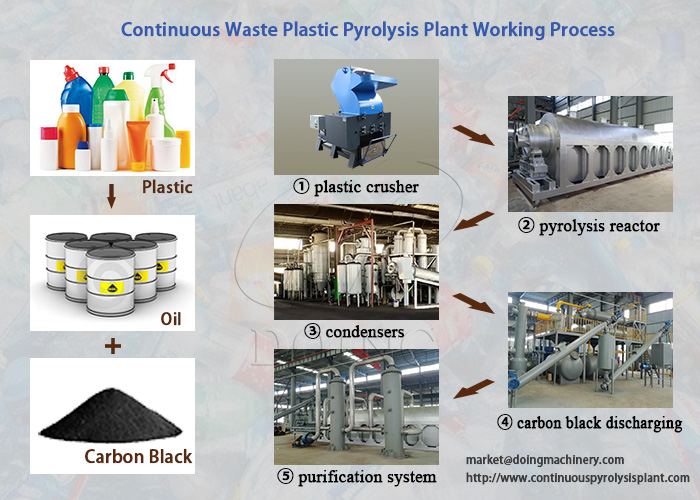

Since waste plastics are difficult to degrade, we generally use pyrolysis plant to recycle them into renewable energy.

The liquid fuel it produces is called fuel oil, which is a new type of energy with a wide range of uses. The process of pyrolysis of waste plastics to fuel oil is: pretreatment, high temperature pyrolysis, condensation, tail gas purification , discharge carbon black and fume treatment.

Let me introduce in detail the process of pyrolysis of waste plastic to fuel oil.

Waste plastic pyrolysis process flow

Waste plastic pyrolysis process flow

1. Pre-treatment

First, the waste plastic is shredded into small pieces to facilitate full pyrolysis and improve production efficiency. Then sealed and fed into the reactor.2. High-temperature pyrolysis

Under high temperature and oxygen-free conditions, the reactor will generate oil and gas after reaching a certain temperature.

3、Cooling

The generated oil and gas will be buffered in the buffer tank and then enter the condensing system for cooling. After passing through the buffer condensing tank, vertical condenser and horizontal condenser in turn, the oil and gas can be effectively condensed into oil, and the condensed oil enters the oil tank.

4、Tail gas purification

After the condensing system, the remaining non-condensable combustible gas contains hydrogen sulfide and other harmful gases, which can be used as fuel for heating the pyrolysis reactor after being treated by the tail gas cleaning and removal system.

5、Discharge carbon black

The continuous waste plastic pyrolysis plant adopts the carbon black discharge cage to connect the end of the pyrolysis reactor for slag discharge, and the whole process is carried out in a sealed environment, which is safer and more environmentally friendly.

6、Fume treatment

The flue gas generated during the heating process of the reactor enters the desulfurization tower for purification and treatment, and then reaches the national environmental protection emission standard and can be discharged into the atmosphere.

Continuous waste plastic pyrolysis plant

Continuous waste plastic pyrolysis plant

The pyrolysis of waste plastic to fuel oil is a good thing that can realize waste recycling and get profit. Doing has both batch and continuous waste plastic pyrolysis plant, which can process different quantities. If you want to know more information, you can contact us at any time.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.