What happens to used tyres ?

Tyre to oil

With the continuous development of industrial civilization, more and more widely used in rubber tyre garbage in our lives , and this phenomenon is discarded rubber tyre waste is serious, it brings huge black pollution of our environment. Meanwhile, as the world economy , the energy crisis is getting worse. Find new ways of energy has been put on the agenda in many countries .

Waste tyre pyrolysis plant is a recovery technology, thermal and catalytic cracking process by plastic or tire fuel , monomers or other waste to energy.

DOING Group began to study the pyrolysis technology, the waste tyre pyrolysis to oil machine, waste plastic to oil energy technologies. After many years of continuous innovation , and now we are proud to introduce the waste tyre pyrolysis plant in briefly.

What happens to used tyres ?

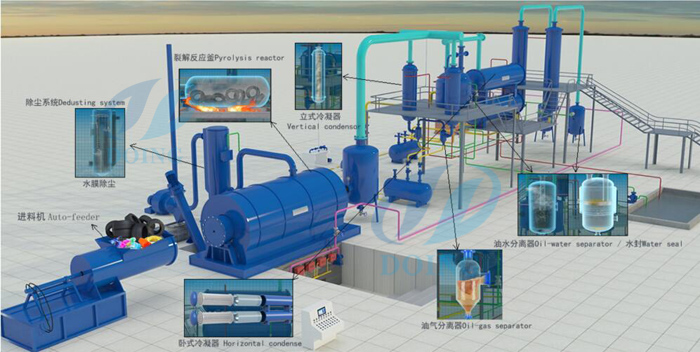

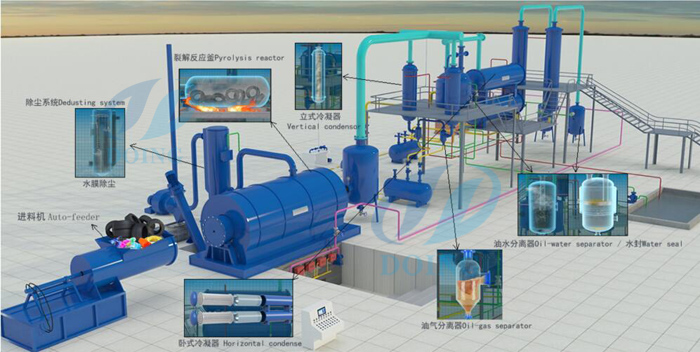

Waste tyre pyrolysis plant pyrolysis process

1. Put pre- processed tyres into the reactor by full-automatic feeding machine(taking the fully continuous tyre pyrolysis plant for example) after they are delivered into stock bin by conveyor belt. Total quantity shall be controlled under 2/3 of reactor for rotating more smoothly. Then close the feeding door and open the heating system.

2. Two stages are included for tyre pyrolysis process. From 100 ℃ to 250 ℃ is the preliminary stage , and the oil gas shall be released at 200 ℃ . From 280 ℃ to 350 ℃ is the top output rate interval. Oil gas will be collected into manifold, and the heavy particles and oil will be gathered and liquefied in center of manifold and drop down into the heavy pyrolysis oil tank. The lighter gas will rise up to the multi-functional oil condensers, then be liquefied into oil and stored in the oil tank. The incondensable gas through desulfuration and de-dusting by hydroseal will be led to the furnace for heating.

3. Cool down the reactor after making sure all above mentioned have been done. The carbon black will be discharged when the temperature reaches at 40 ℃. The end products you can get from the waste tyre to oil process are tyre pyrolysis oil, carbon black, steel wire and combustible gas.

Waste tyre pyrolysis plant not only can process waste tyre,but also can process plastic,rubber to fuel oil, Fuel oil can be as a heating material apply to heavy industies,such as,cement factory, glass making factory, steel factory, boiler etc.