WhatsApp

WhatsApp

Due to the booming use of automobiles and industrial activity, millions of tires pile up each year, consuming significant land resources and resisting natural degradation. For countries facing large volumes of waste tires, effective management is crucial to avoid environmental pollution while unlocking their economic value. As a leading tire pyrolysis equipment manufacturer, DOING offers a proven solution to turn tire scraps into usable resources. Below, we break down countries with high old tire output and how DOING tire pyrolysis equipment addresses this issue.

Which countries have a high amount of old tires?

Old tire volumes are closely tied to three factors: automotive ownership rates, industrial activity (e.g., logistics, mining), and population size. The following countries and regions stand out for their high old tire output:

1.China: Rapid urbanization and growth in logistics and delivery services have driven tire demand.

2.United States: High car ownership, a large commercial fleet (trucks, buses), and historical reliance on landfilling make tire waste a pressing issue.

3.India& Indonesia: Rising middle-class car ownership and a booming two-wheeler market (motorcycles and scooters, which use smaller tires but have shorter lifespans) are the main drivers.

4.EU: Germany, France, and Italy generate the most waste tires annually. Strict landfill bans push recycling, but high volumes still demand scalable processing.

5.Brazil: A large agricultural sector (using farm vehicles with heavy-duty tires) and growing urban automotive use contribute to this.

6.South Africa: South Africa's road transport industry occupies an important position on the African continent. The number of motor vehicles continues to grow, resulting in a corresponding increase in the generation of waste tires.

DOING tire scrap pyrolysis machine cases

DOING tire scrap pyrolysis machine cases

Currently, these countries have a significant and growing supply of waste tires, necessitating appropriate waste tire management solutions. In addition to establishing and implementing comprehensive waste tire recycling strategies, a full industry chain responsibility system, or providing processing subsidies, we also recommend minimizing and repurposing waste tires.

Traditional methods (landfilling, incineration) harm the environment—landfills leak toxins, while incineration releases pollutants. Tire pyrolysis is the optimal alternative: it uses oxygen-free thermal decomposition (350–550°C) to convert tire scraps into three high-value products: tire pyrolysis oil, carbon black, syngas. DOING tire pyrolysis equipment optimizes this process for efficiency and compliance.

How to manage tire scraps:

1.How to develop a tire scraps pyrolysis business

The 1st step: You should get a piece of a land for putting DOING tire pyrolysis equipment. Open land is sufficient, but an enclosed building of appropriate height is preferred.

The 2nd step: Inform DOING of your country's local environmental standards and obtain environmentally friendly equipment.

The 3rd step: Obtain approval from the local government.

The last step: Purchase and install the DOING tire pyrolysis equipment. During the equipment installation process, we will dispatch engineers to conduct commissioning and trial operation.

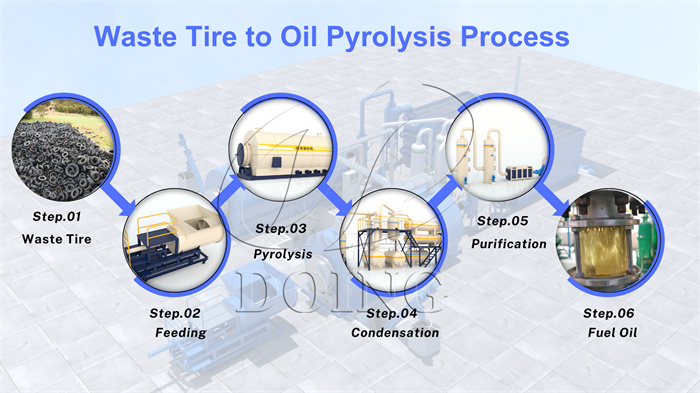

DOING tire scrap pyrolysis machine process

DOING tire scrap pyrolysis machine process

2.How to operate DOING tire pyrolysis equipment

Feeding: Feeding the tire scraps enter a sealed pyrolysis reactor.

Heating: Heating the pyrolysis to 350–550°C (no oxygen), rubber polymers break into hydrocarbon vapors.

Cooling: Vapors are cooled and condensed into liquid fuel (40–45% yield, calorific value 42–45 MJ/kg, usable for boilers/generators)

Collecting: Carbon black (30–35% yield) for rubber/ink production, steel wire (15% yield) for reuse. Non-condensable gases (6% yield) are redirected to fuel the heating process.

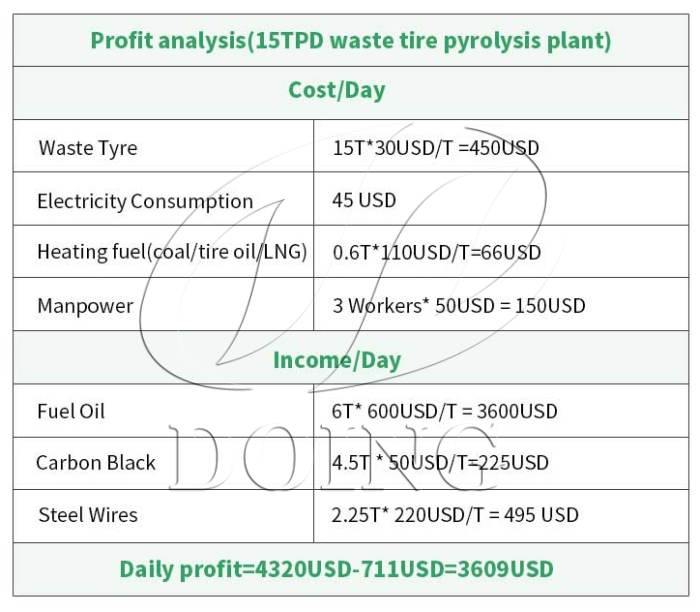

Through DOING pyrolysis technology, countries like China, U.S., India, Indonesia, Germany, France, Italy, Brazil, South Africa, which have large quantities of tires scrap, can not only reduce this black pollution but also produce valuable alternative fuels and carbon black resources, extending the lifecycle and output value of these waste tires while reducing their carbon footprint. Our Henan DOING Company has assisted several international companies in establishing tire recycling management programs. For example, a single 15-ton tire pyrolysis equipment can process 5,475 tons of waste tires annually, producing 2,190 tons of fuel oil, 1,642.5 tons of carbon black, and 821.25 tons of steel wire, generating a profit of approximately $1.3 million. This represents significant environmental and economic benefits.

DOING tire scrap pyrolysis machine profit analysis

DOING tire scrap pyrolysis machine profit analysis

If your country or region faces challenges with old tire management, DOING tire pyrolysis equipment can help turn this waste into a revenue stream. Contact our team today to learn more about our projects, request a customized quote, or schedule a virtual factory tour.

contact us

CONTACT US