Crude oil generated process

Crude oil is basically the remains of plants and marine life that died millions of years ago. Over time, these fossil remains - hence called "fossil fuels" - are buried under the sand and slowly form rocks. Millions of years later, the remains of fossils slowly "cured" into black liquids that we think are crude oils. The crude oil then drills through the giant drill bit from the bottom of the sea and drills deep into its trapped area.

DoingGroup's diesel oil made from crude oil machine

Since crude oil is a black viscous material, its use will be very limited if it is not reprocessed. The DoingGroup's diesel oil made from crude oil machine can make up for this defect and refine crude oil into non-standard diesel oil. So that it has a wider range of use.

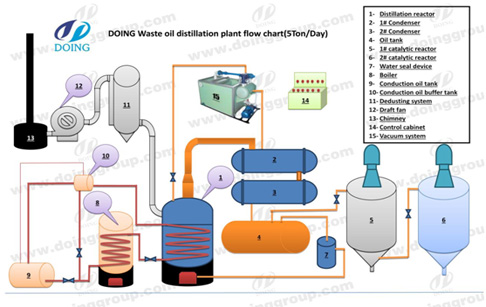

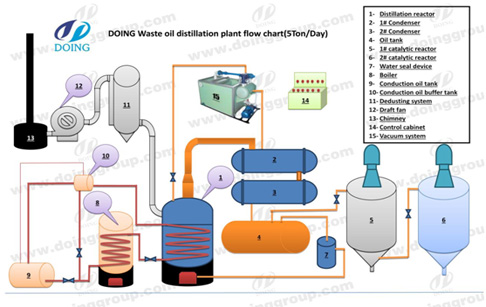

So how is diesel oil made from crude oil machine working process?

Diesel oil made from crude oil working process

1. Pour the crude oil into the reactor and heat the reactor at a high temperature. Distillation heating, commonly referred to as distillation, distills oil and gas residues from the crude oil.

2. The distillate oil and gas enters the condensing system under the action of high and low pressure. After being cooled, it is liquefied into light oil and falls into the oil tank.

3. The light oil obtained is subjected to desulfurization and degreasing, and finally the refined diesel is obtained.

4. Finally remove the asphalt separated after distillation.

DoingGroup's diesel oil made from crude oil machine

The ability to obtain such a high oil yield is closely related to the following advantages of the DoingGroup's diesel oil made from crude oil machine:

1. The reactor adopts a vertical design, which can realize automatic slag discharge, convenient and quick.

2. Double heating system, heating time period, improve equipment operation efficiency.

3. The cooling method is water circulation cooling, water will be recycaled, almost no consumption.

4. Semi-continuous equipment, moderate investment, high operation efficiency.

Technical parameters of diesel oil made from crude oil machine

|

Technical parameter of diesel oil made from crude oil machine |

|

Items |

Contents |

|

Model |

DY-5t, DY-10t, DY-20t, DY-50t… |

|

Raw material |

motor oil, waste tire crude oil, plastic crude oil |

|

Structure form |

Vertical (easy cleaning and maintenance) |

|

Heating method |

Indirect heating to prolong the machine service life |

|

Operating pressure |

Constant pressure |

|

Heating material |

Coal, charcoal, fuel gas, fuel oil |

|

Average out-put oil rate |

95% |

|

Material of reactor |

4 reactor with different material |

|

Thickness of reactor |

18mm |

|

Mode of cooling |

Recycled water cooling |

|

Power in total |

20 Kw |

|

Service life |

average 7 years |

|

Land area |

180㎡ |

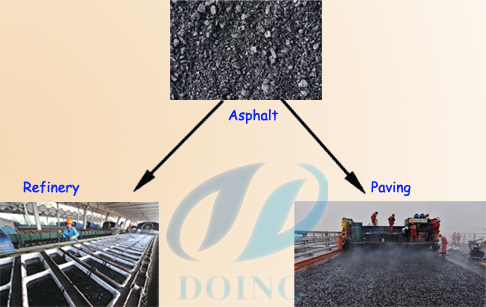

Diesel oil made from crude oil machine can finally get 80-85% diesel and 15-20% asphalt. They have a very wide range of use values:

Diesel oil usage

1. Diesel oil: Can be used for heavy machinery, diesel generators, boiler heating.

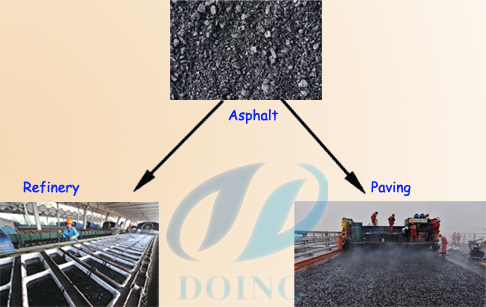

Asphalt usage

2. Asphalt: It can be used directly for road paving or sent to asphalt plants for refining.

WhatsApp

WhatsApp