WhatsApp

WhatsApp

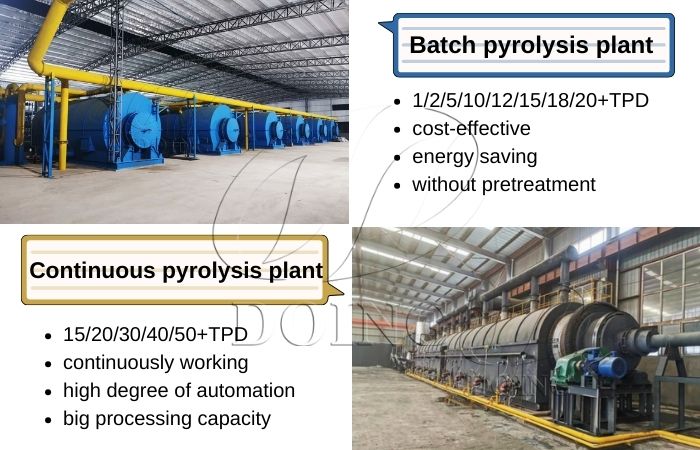

After many technological updates and iterations, the pyrolysis technology has become mature and stable. Now there are continuous and batch type pyrolysis plants for customers to choose from. Then what are the differences between continuous and batch pyrolysis technology? And which one is better? Here we list some details for your reference.

Batch continuous pyrolysis plant differences

Batch continuous pyrolysis plant differences

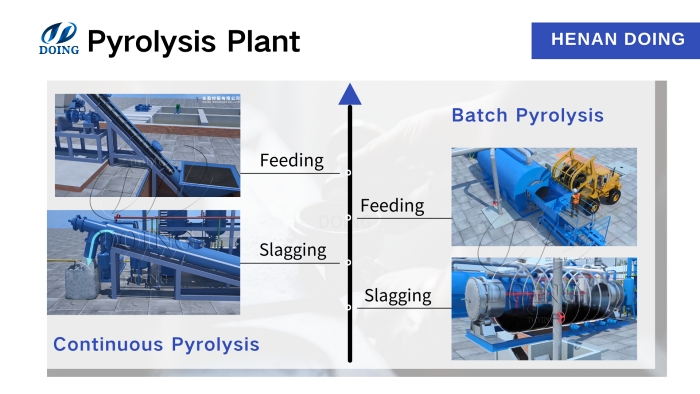

①Operation: The continuous pyrolysis plant realizes 24 hours continuous operation under the premise of safety and environmental protection. One furnace can continuously feed tire rubber powder from the feed port and continuously discharge slag from the discharge port at the other end. There is no need to open the furnace door during production and operation, which is fully enclosed operation.

And for batch type pyrolysis plant, workers should fill the raw material, for example, the waste tyre/plastic with a batch of raw material and take the process, and then after cooling down and removal of the carbon black&steel wire, the next process will happen.

For a 10-ton batch pyrolysis plant, the feeding time is about one and a half hours, processing time for eight to nine hours, cooling time for five hours, and slagging out time for one hour. In this process, the steel wire should be pulled out by people. It is more traditional, so it is cheap enough for people who haven’t prepared enough funds for this project.

Batch continuous pyrolysis plant differences

Batch continuous pyrolysis plant differences

②Slagging: Continuous pyrolysis plant makes use of automatic slag-out system, thus it doesn’t need any labor force to take out the slag. On the contrary, the batch type pyrolysis plant isn't equipped with the automatic slag-out system, therefore, it needs to be slagged out by workers. What’s more, the slag-out process is supposed to be started after the furnace cooled down completely. The equipment doesn’t stop for 24 hours. This is why we call it automatically continuous pyrolysis plant. It is more convenient and sufficient than the batching pyrolysis plant.

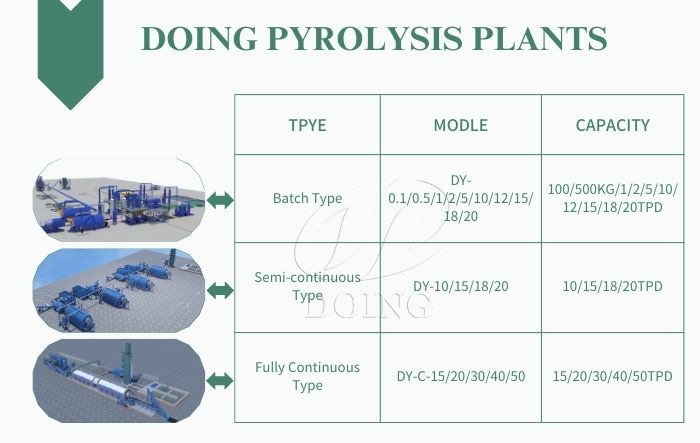

The continuous pyrolysis plant has a daily processing capacity of 15-50 tons, with large processing capacity and high production efficiency. While the daily processing capacity of a single batch pyrolysis plant is 100kg to 20 tons. The processing capacity is slightly smaller and the operating efficiency is slightly lower.

Capacities of DOING batch continuous pyrolysis plant

Capacities of DOING batch continuous pyrolysis plant

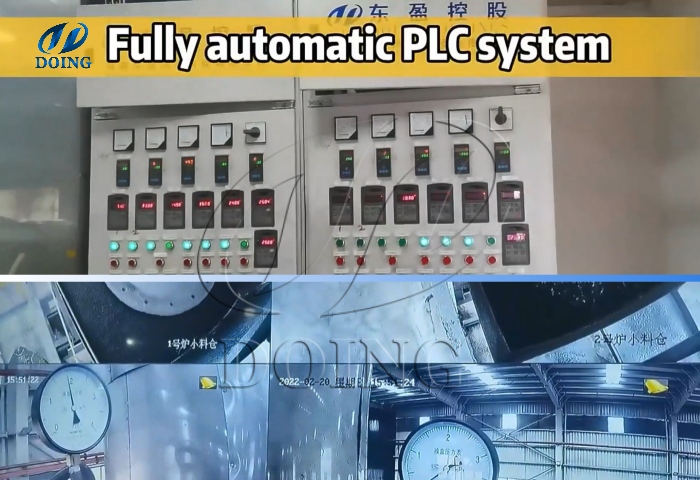

The continuous pyrolysis plant adopts PLC intelligent control and requires less labor. There are only 1-2 people in a single production line and the labor intensity is low. Batch pyrolysis plant requires manual or automatic feeders to feed materials, manual pulling of wires, and semi-automatic production operations. A single production line requires 3-4 people, and requires more staffing.

PLC control system of continuous pyrolysis plant

PLC control system of continuous pyrolysis plant

The continuous pyrolysis plant is in line with the development direction of airtightness, continuous, automation, environmental protection and intelligence, and is a national encouraged development project. Batch pyrolysis plant also complies with national policy requirements and environmental protection requirements, but in the long run, there is a possibility of being replaced during the equipment update process.

Batch continuous pyrolysis plant projects

Batch continuous pyrolysis plant projects

Therefore, investors who are still struggling with how to choose pyrolysis plant can make a choice based on the above differences between continuous and batch pyrolysis plant, as well as your own circumstances and needs. All customers are welcome to send inquiries, and our managers can also customize the most cost-effective equipment solution for you based on your actual situation.

contact us

CONTACT US