WhatsApp

WhatsApp

As the pollution caused by waste tyres is getting worse, how to dispose the waste tyres for recycle use has been the hot concern for a long time. After years study, waste tyre pyrolysis to fuel oil is accept by public. That’s why waste tyre oil extraction and pyrolysis plant was developed.

Waste tyre oil extraction and pyrolysis plant for sale

Waste tyre oil extraction and pyrolysis plant for sale

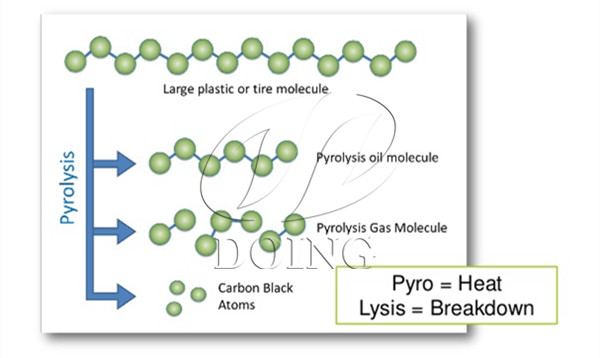

Tyre is mainly made of rubber, carbon black, zinc oxide, sulphur and other organic components. Through pyrolysis process, tyres could be decomposed into pyrolysis oil, pyrolysis carbon black and pyrolysis gas. And tyre pyrolysis is usually happened in a sealed and oxygen-poor environment with the temperature of 400-450℃.Of course, different type rubbers have different thermal decomposition temperature. For natural rubber, since its weak hot nature, its pyrolysis temperature is also lower. For styrene butadiene rubber and butadiene rubber, the pyrolysis temperature is higher.

Waste tyre pyrolysis

Waste tyre pyrolysis

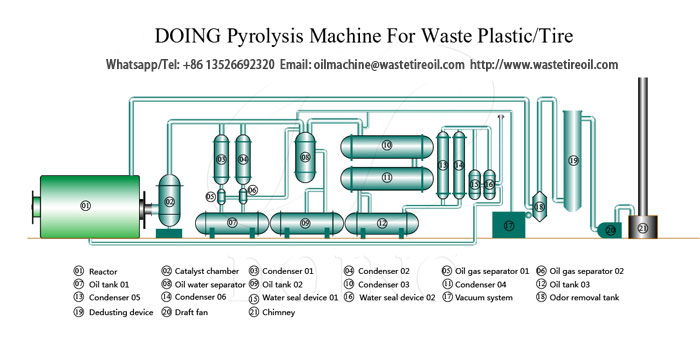

What’s the working process of waste tyre oil extraction and pyrolysis plant?

For the waste tyre oil extraction and pyrolysis plant developed by DOING, it mainly include tyre pretreatment system, tyre feeding device, tyre pyrolysis reactor, oil gas cooling system, tail gas cleaning system, smoke cleaning system, carbon black discharge device, etc. Firstly, waste tyres would be loaded into the pyrolysis plant, then start heating. About 3 hours later, pyrolysis oil gas would come out from the reactor and flow into the cooling system to be condensated to pyrolysis oil. At the same time, the pyrolysis gas which is uncondensable, which would flow into the tail gas cleaning system to be cleaned and recycled to heat the pyrolysis reactor. Normally the tyre pyrolysis process could be finished in 8-10 hours. After that, the residues (carbon black and steel wire) inside pyrolysis system need to be discharged out after pyrolysis reactor cools down. Meanwhile, the smoke generated from the fuel burning furnace would be filtered by the smoke cleaning system before release out.

Waste tyre oil extraction and pyrolysis plant for sale process

Waste tyre oil extraction and pyrolysis plant for sale process

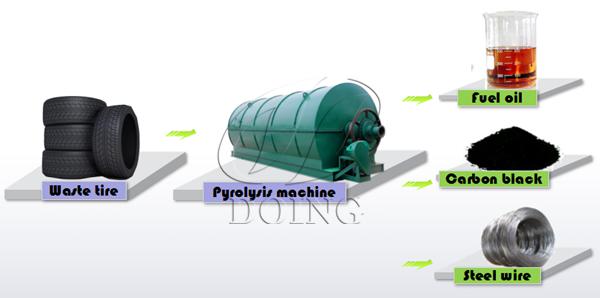

What benefit you could get from the waste tyre oil extraction and pyrolysis plant?

1. Environmental benefit

Firstly, waste tyre oil extraction and pyrolysis plant could dispose waste tyres to fuel oil, carbon black, combustible gas and steel wire for recycle use without generate secondary pollution. That means waste tyre oil extraction and pyrolysis plant could solve the waste tyre pollution, bring benefit to environment.

2. Economic benefit

From waste tyre oil extraction and pyrolysis plant, the end products would be oil, carbon black, combustible gas and steel wire, which all could be reusable and bring benefit to the plant operator.

Waste tyre oil extraction and pyrolysis plant

Waste tyre oil extraction and pyrolysis plant

Below we provide you some guidance for the end products use:

1) Pyrolysis oil is the main product from waste tyre oil extraction and pyrolysis plant, which usually has the yield of 40-50%, with the density of 900-950kg/m3 and heating value of 40-43MJ/kg. As its high heating value, the pyrolysis oil could be directly used as heating fuel in industrial factories for boiler use, or to be further refined to clean diesel fuel for more use.

2) Pyrolysis carbon black is the second product from waste tyre oil extraction and pyrolysis plant, which could be recycled to be used as additives for tires and rubber products, or electrode material, composite material, printing ink, asphalt mofifier, coloe master batch, etc.

3) Pyrolysis gas, as we all know, usually is directly recycled to the furnace for heating the pyrolysis reactor. By analyzed through gas chromatography, the main component of pyrolysis gas include alkane, alkene, benzene, methylbenzene, xylene, hydrogen, nitrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, etc. And the gas distribution is mainly to ethylene, then propylene, butane, isobutene, etc. Except hydrogen and methane, the others are mainly C2, C3 and C4 content. Since its stable quality and low sulphur content, the pyrolysis gas could directly used as industrial and household fuel. And the heating value of pyrolysis gas is rather same as nature gas, which also could be used for steam or turbine generator.

4) Steel wire, it’s easy to be sold as scrap iron or recycled to the steel mill for remelting and making new steel products.

contact us

CONTACT US