WhatsApp

WhatsApp

What's waste tyre recycling pyrolysis plant?

Waste tyre recycling pyrolysis plant is for recycling waste tyres to renewable energy through a thermal cracking process. The whole process of waste tyre recycling pyrolysis plant is under sealed environment with tail gas cleaning system, without generating secondary pollution to the air.

Waste tyre recycling pyrolysis plant in operation

Waste tyre recycling pyrolysis plant in operation

What benefit you could get from the waste tyre recycling pyrolysis plant?

1) Social benefit: By using the waste tyre recycling pyrolysis plant, you could dispose waste tires dump and landfill, solve the black pollution to the environment, clean the city to people; Also when you open a new business, like running the waste tyre recycling pyrolysis plant, you could creat the job opportunity to some people. Good for you, good for society.

2) Economic benefit: Through waste tyre recycling pyrolysis plant, the direct benefit you get is the renewable end products, include tire pyrolysis oil, carbon black, steel wire and syngas.

Tire pyrolysis oil is the main product of the waste tyre recycling pyrolysis plant. It's a kind of heavy fuel oil with the calorific value of 42MJ/kg, which could be directly used as heating fuel for boilers and furnaces in any industrial factories, like power plant, cement factory, steel factory, etc. Also tire pyrolysis oil could be further refined to clean fuel, used as diesel in generators, trucks and farm machinery.

Carbon black as the second product of the waste tyre recycling pyrolysis plant also has its own use value. Firstly, it could be directly sold as crude carbon black in the market; Secondly, since it has the calorific value of 7000Kcal as high as coal, it could be briquetted into pellets used as heating fuel, too; Thirdly, the crude carbon black directly produced from waste tyre recycling pyrolysis plant could be further refined to finer size used for making new products again, like 325mesh carbon black used for making paint or ink, 800-2500 mesh carbon black used as additives in rubber production industry.

Then, the other visible product is steel wire, which is easy to see its market. Through the high temperature process of the waste tyre recycling pyrolysis plant, steel wire inside waste tyres is not as new as raw steel wire, so it's usually directly sold as scrap to recycling station, but as we all know that steel wire price is not low, also could bring you good addtional profit.

As for the syngas, it's generally directly recycled to the furnace usd as fuel for heating the waste tyre recycling pyrolysis plant. This way, it could save the storage cost and fuel cost for you, of course another kind of benefit for you. So you could see, there is even no waste or loss from the waste tyre recycling pyrolysis process. All the waste could be recycled to renewable energy or valuable products.

Waste tyre recycling pyrolysis plant product

Waste tyre recycling pyrolysis plant product

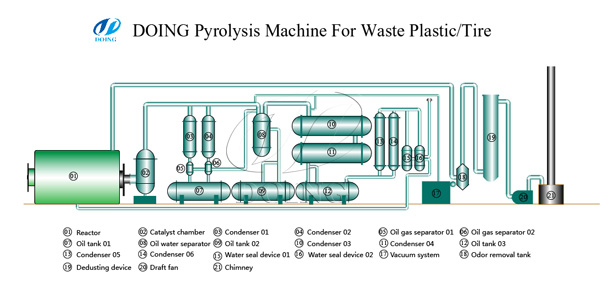

What's the process of waste tyre recycling pyrolysis plant?

1. Collect waste tyres, and feed required amount of the tyres into the reactor of the wastet tyre recycling pyrolysis plant;

2. Start heating;

3. About 3 hours heating, there would be oil gas produced. Then oil gas will flow into the following cooling system to be cooled down to liquid oil. The waste tyre pyrolyzed to oil process usually takes about 10 hours;

4. After pyrolysis process finished, stay the reactor there to be cooled down, then start to discharge carbon black and steel wire.

5. After slagging, start another process.

Waste tyre recycling pyrolysis plant process

Waste tyre recycling pyrolysis plant process

What's the specification of the waste tyre recycling pyrolysis plant?

| Technical parameter of waste tyre recycling pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

contact us

CONTACT US