WhatsApp

WhatsApp

At present, the waste plastic recycling industry has achieved great development and progress, its production process has reached a certain level and height, and the future development prospects remain good. If you want to convert waste plastic to fuel oil at home first, then expand the production, then here is some information for your reference.

Waste plastic to fuel oil converter pyrolysis plant

Waste plastic to fuel oil converter pyrolysis plant

1. Which kind of waste plastic raw materials is available for recycling into fuel oil? Adequacy of supplies of it?

Available waste plastic recycling raw materials: discarded polyethylene, polypropylene, polystyrene, polyester, etc., such as the daily life of the waste plastic film, agricultural film, the convenience of bags, woven belt, packaged tape, packing foam, foam lunch boxes, a variety of electrical enclosures, paper mill waste, houseld plastic scrap, medical plastic scrap, waste soles, organic glass, plastic pots barrel and plastic products, scrap, etc., which can be used as the raw material of waste plastic pyrolysis.

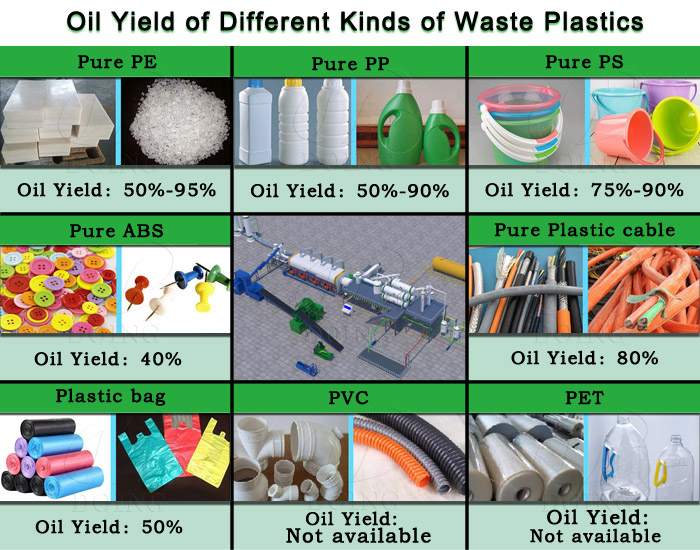

Waste plastic pyrolysis to fuel oil conversation rate

Waste plastic pyrolysis to fuel oil conversation rate

Note: Commonly speaking, PP, PE, PS, ABS plastic, etc. can be used for pyrolysis into fuel oil. But PVC and PET plastic is not suitable for pyrolysis into fuel oil.

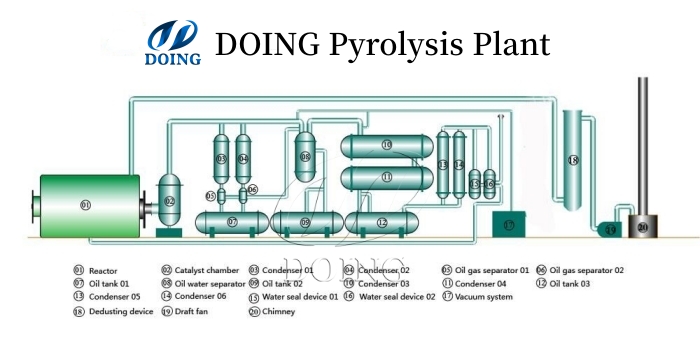

2. Waste plastic to fuel oil conversation process

Henan Doing Company has been engaged in fabrication of waste plastic pyrolysis plants for years. as a leading pyrolysis plant manufacturer and supplier, we provide a new technology pyrolsis machine to convert waste plastic to oil machines. You can choose the mini small scale skid-mounted type 100KG/500KG plastic pyrolysis plant, which has the advantages of free installation, small footprint, easy handling.

Mini small scale skid-mounted waste plastic pyrolysis plant for sale

Mini small scale skid-mounted waste plastic pyrolysis plant for sale

The plastic to fuel oil conversation process includes:

1. Put waste plastic into the pyrolysis reactor, then close the door.

2. Heat the pyrolysis reactor with wood, coal, fuel oil or gas. When temperature reaches 100 degrees, waste plastic pyrolysis process starts in the pyrolysis plant reactor. And then oil gas comes out from the oil outlet.

Waste plastic to fuel oil conversation process

Waste plastic to fuel oil conversation process

3. When oil gas from reactor goes through buffer tank, top cooling pipe, oil- waster separator, heavy oil is collected in the heavy oil tank. Other uncondensable oil gas continues to go through the purification system and then can be used for heating reactors to save investment cost.

Plastic pyrolysis fuel oil is a good heating fuel, which can be used for heating various boilers, furnaces, heavy industries like steel factories, cement factories, brick factories, heavy oil power plants, etc.

4. When all the oil gas is extracted out, only carbon black is left in the pyrolysis plant reactor. After reactor cooling down below 50°, carbon black can be discharged. After process with a magnetic separator, carbon black mix with organic chemical adhesive can be used to make coal briquette. The calorific value reaches 6000 calories. It is a very good energy used to heat furnaces and boilers.

If you need related mini small scale skid-mounted waste plastic pyrolysis plant to convert waste plastic into fuel oil at home and purchase it at favorable prices, welcome to contact us for free quotations.

contact us

CONTACT US