Why fully continuous waste plastic pyrolysis plant so popular?

Waste plastic

On one hand, with the moderation of the society, rubber industry is developing at a rapid speed, rubber products are widely used in many field of life, on the other hand, the pollutant of rubber, increasing for its difficulty in decomposing, which was called “Black Contamination”, has became a big threat to the environment and get increasingly serious. Compared to the developed countries, we are still lack of experiences in treating the pollution the capital and market are also big problems.

So to set up a pyrolysis plant factory in each town, which could extract carbon black powder and plastic oil (pyrolysis oil) from 65-million wasteplastics, it is easy to find the raw material.

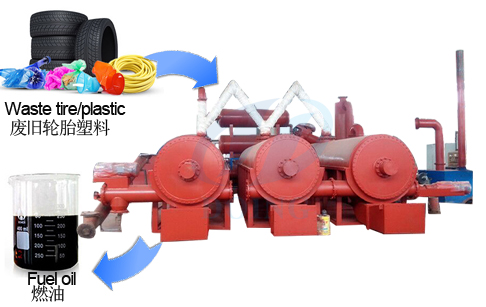

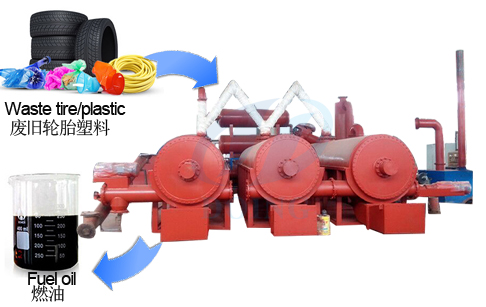

Fully continuous waste plastic pyrolysis plant is an environmental protection system which uses the continuous liquefaction technology and catalytic breakdown reaction to convert waste plastics into renewable resources, such as pyrolysis oil, carbon black, combustible gas and so on

Application of fully continuous waste plastic pyrolysis plant

Application of fully continuous waste plastic pyrolysis plant

Application of fully continuous waste plastic pyrolysis plant

For our fully continuous waste plastic pyrolysis plant,the applicable raw materials can bepolythene,polypropylene,polystyrene,ABS...

The final products from plastics continuous pyrolysis process will be fuel oil and carbon black.

Fully continuous waste plastic pyrolysis plant advantage

Fully continuous waste plastic pyrolysis plant

1: Fully automatic with low labour cost

Our fully conitnuous waste plastics pyrolysis plant is controlled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

2:Fully pyrolysis for high oil output

Our fully continuous waste plastics pyrolysis plant adapts to multiple reactor design which can make fully pyrolysis of waste plastics, thus to get high oil output.

3:Big capacity

Also due to continuous feeding and discharge system, and unique multiple reactor design, our fully automatic continuous waste plastics pyrolysis plant can process at least 10 tons waste plastics per day, up to 100T/D.

4: Internal rotating for continuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve he real sense of continuous process. But our continuous waste plastics pyrolysis reactor adapts internal rotating method, which no need to worry about the sealing of the external rotating system.Continuous working save time and energy

5:Long working life

During the continuous pyrolysis process, reactor is heated by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors.

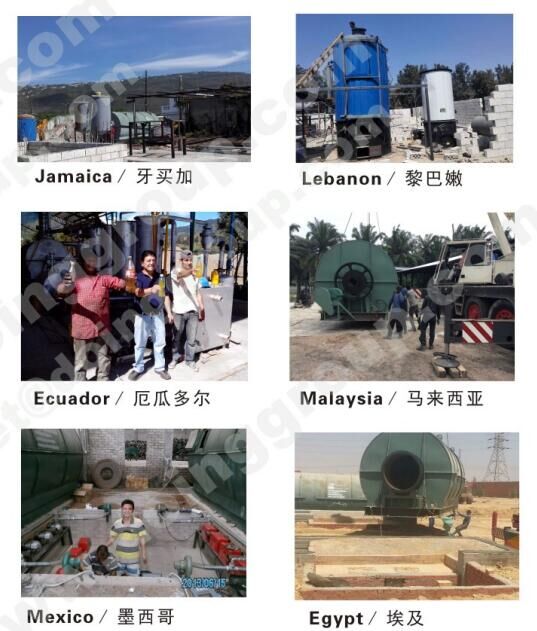

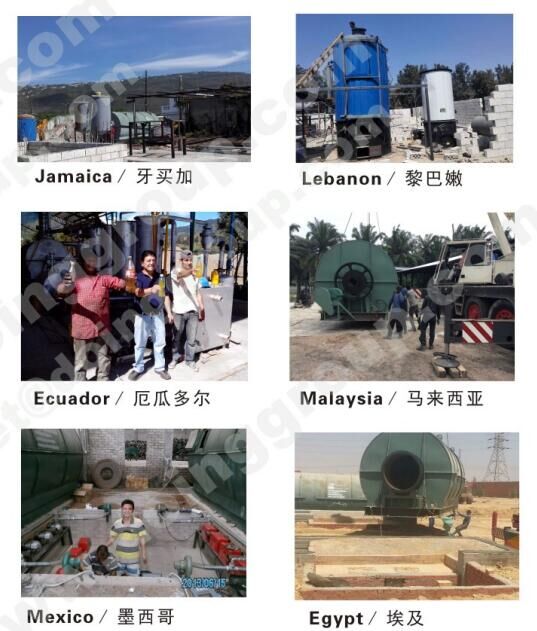

Pyrolysis plant installed in different countries

With the improvement of our technology and the growing of foreign trade business, Doing has opened our international market preliminarily. Our machinery have been sold to Italy, Romania, Macedonia, Albania, Estonia, Rusia, Egypt, Ethopia, Nigeria, Congo, Lebanon, Jordan, Iran, Pakistan, Kazakhstan, India, Tailand, Malaysia, Mexico, Panama, Guatemala, Aruba, Jamaica, Ecuador, Haiti etc.

Our considerate service is highly appreciated by foreign governments and customers. Doing promises we have and always will serve customers with high quality turnkey and plant output.

Technical data of fully continuous waste plastic pyrolysis plant

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tire/plastic/rubber |

|

12 |

Output |

Fuel oil, carbon black |

Final product applicatin of fully continuous waste plastic pyrolysis plant

Fully continuous waste plastic pyrolysis plant is a very good investment, not only can efficiently deal with a large number of abandoned plastic, turn waste into treasure, but also can avoid environmental pollution caused by landfill or burning these waste.

Fuel oil application