WhatsApp

WhatsApp

|

Technical datar of Pyrolysis of plastic to oil process machine |

||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

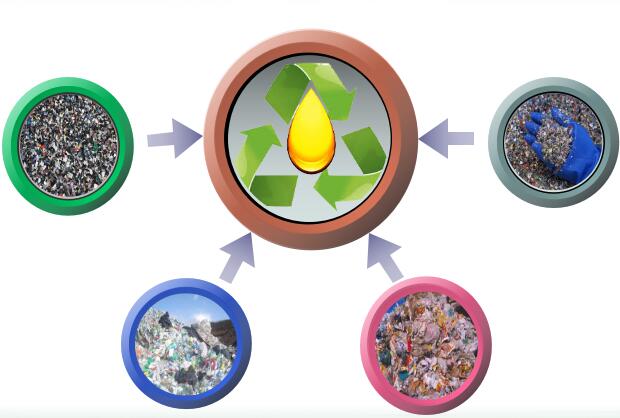

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Pyrolysis of plastic to oil process machine | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

contact us

CONTACT US