WhatsApp

WhatsApp

Waste plastic pyrolysis machine can convert waste plastic into fuel oil and carbon black. Since the whole running process of waste plastic pyrolysis machine meets the environmental protection standard, and the final products including fuel oil and carbon black have a good market in many countries, waste plastic pyrolysis machine project is becoming more and more popular. Doing Company has two kind of waste plastic pyrolysis machine: Batch waste plastic pyrolysis machine and continuous waste plastic pyrolysis machine. You can choose the most suitable equipment accoeding to your needs.

Batch waste plastic pyrolysis machine

Batch waste plastic pyrolysis machine

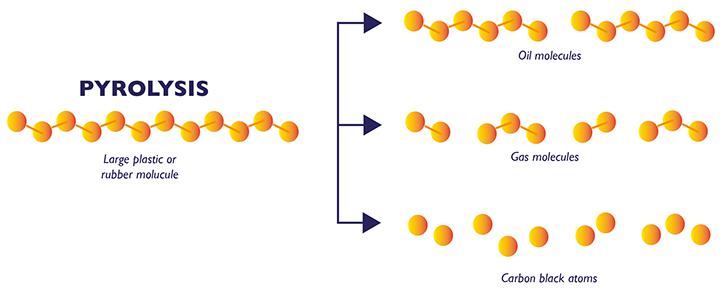

♦ Working principle:

Batch waste plastic prolysis plant uses pyrolysis technology, which can break down high molecular compounds into low molecular compounds in an oxygen-free environment.

Pyrolysis (Pyro = heat Lysis = break down)

Pyrolysis (Pyro = heat Lysis = break down)

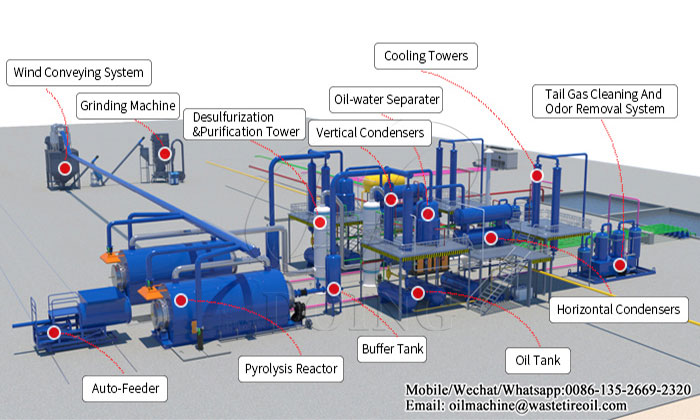

♦ Components:

Batch waste plastic pyrolysis machine consists of pyrolysis reactor, buffer tank, condensing system, oil-gas separator, tail gas purification device and desulfurization tower, etc.

Batch waste plastic pyrolysis machine 3D image

Batch waste plastic pyrolysis machine 3D image

♦ Operation process:

First, put waste plastic into the pyrolysis reactor by the feeder. Close the inlet of the pyrolysis reactor to ensure safety.

Second, heat pyrolysis reactor with fuel like coal, wood, fuel oil, gas. When the pyrolysis reactor reach a certain temperature, the oil gas will generate.

Third, liquify oil gas into pyrolysis oil through four-stage cooling system including buffer tank, vertical condensers, horizontal condensers and condensing towers. The cooling system can ensure adequate contact area and high oil yield. The liquid oil will then be collected into the tank.

Fourth, some uncondensable gas will go through tail gas purification system and then be recycled to heat pyrolysis reactor.

Fifth, the flue gas from combustion of fuel in the heating furnace is exhausted after passing through the desulfurization tower to meet environmental protection standard.

Finally, after completing the pyrolysis, the carbon black will be automatically discharged through the carbon black screw elevator.

♦ Main features:

Safety:

1. Reactor with auto welding to guarantee the quality of welding seam and avoid cracking.

2. Professional heating treatment and x-ray detection chamber for welding seam.

3. Vacuum system to prevent oil gas be back to reactor causing accident.

4. with temperature meter, pressure meter and safety valve.

Environment friendly:

1. Dedusting system to prevent gas and dust from coal burning.

2. The exhaust gas will be recycled for heating reactor, no gas pollution.

3. Well sealing on every junction parts to prevent gas leak, no smelly.

Longer life:

1. Use Q245R special steel plate, thickness 16mm.

2. Adopt welding seam with auto welding, get heating treatment and x-ray detection to extend the life of reactor to the most extend.

Energy saving:

1. Well sealed for heating system, no gas leak and saving fuel.

2. Tail gas recycling system can recycle combustible gas for heating pyrolysis reactor to save energy.

| Technical parameter of waste plastic pyrolysis machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre/plastic | Waste tyre/plastic | Waste tyre/plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

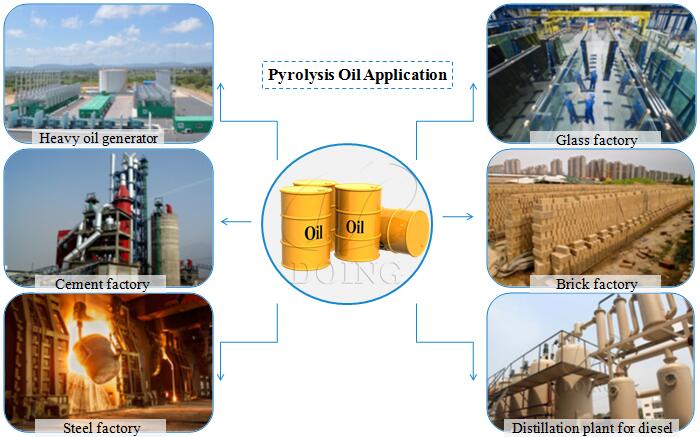

The final products are mainly pyrolysis oil and carbon black, which can be applied in many industries.

1. Pyrolysis oil: Pyrolysis oil can be used as fuel oil for steel plants, heavy oil generators, cement plants and other large factories.

Pyrolysis oil applications

Pyrolysis oil applications

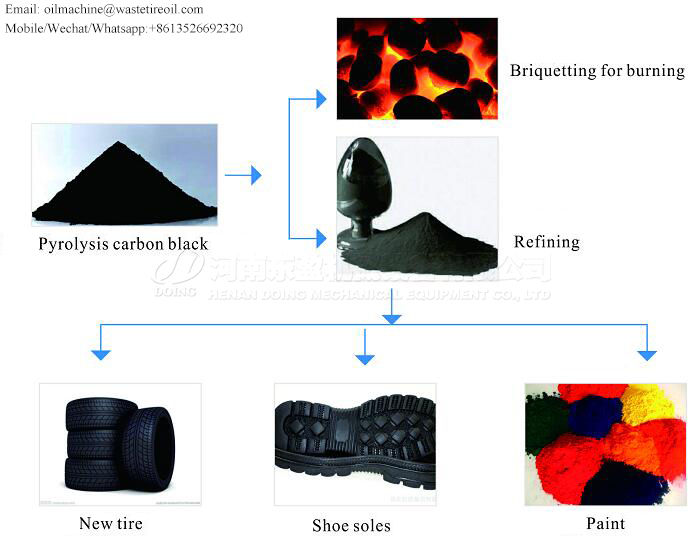

2. Carbon black: Carbon black can be pressed into briquette and then sold as fuel or processed into powder used as a raw material for tires, rubber shoe soles or pigments.

Carbon black applications

Carbon black applications

Doing batch waste plastic pyrolysis machine has been sold to more than 70 countries and regions. We have small batch waste plastic pyrolysis machine of 500 kg or 1 ton/day, batch waste plastic pyrolysis machine of 10, 12, 15 ton/day and continuous waste plastic pyrolysis machine of 20, 30, 50 ton available and we can also provide customized machines according to your specific situation. If you are planning to buy this equipment, please contact us directly.

contact us

CONTACT US