India Gujarat PCB Approves Continuous Pyrolysis Plants

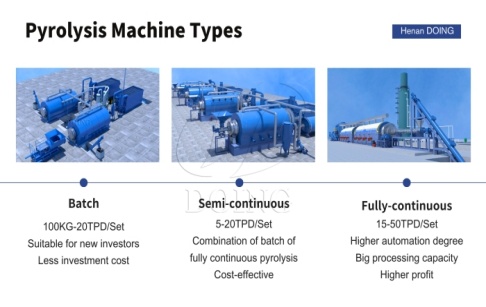

June 24,2025The Gujarat Pollution Control Board (GPCB) in India approved the operation of Continuous Pyrolysis Plants, in addition to the Advanced Batch Automated Pyrolysis Process, aiming to boost waste tyre and rubber recycling efforts.

English

English Русский

Русский Français

Français Español

Español Tiếng Việt

Tiếng Việt 한국인

한국인 日本語

日本語 แบบไทยไทย

แบบไทยไทย Indonesia

Indonesia Deutsch

Deutsch Português

Português عربي

عربي हिन्दी

हिन्दी Українська

Українська Türkçe

Türkçe Malaysia

Malaysia Italiano

Italiano