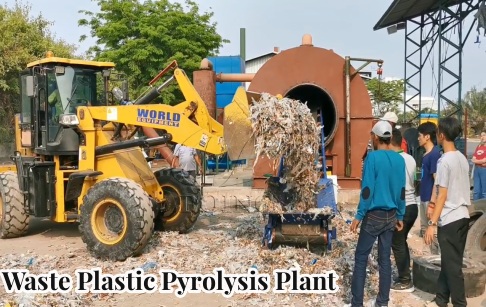

What are the input costs, output, and net profit of plastic pyrolysis equipment?

February 6,2026Plastic pyrolysis equipment converts waste plastic into pyrolysis oil and carbon black. Input costs include pyrolysis equipment, feedstock, and fuel. Daily net profit can reach approximately $1,500.

English

English Русский

Русский Français

Français Español

Español Tiếng Việt

Tiếng Việt 한국인

한국인 日本語

日本語 แบบไทยไทย

แบบไทยไทย Indonesia

Indonesia Deutsch

Deutsch Português

Português عربي

عربي हिन्दी

हिन्दी Українська

Українська Türkçe

Türkçe Malaysia

Malaysia Italiano

Italiano