WhatsApp

WhatsApp

As the agricultural center of West Bengal, Kolkata has abundant raw materials for charcoal production, such as coconut shells and rice husks. In addition, the abundant wood resources in Kolkata, India also provide excellent opportunities for charcoal production. As an important industrial equipment, charcoal making machine is widely used in various charcoal production activities and is attracting more and more attention from enterprises and individuals. As a manufacturer focusing on the research and development and production of charcoal making machines, we understand that many Kolkata customers have a keen interest in the price of equipment.

Charcoal making machine for India charcoal production

Charcoal making machine for India charcoal production

The price of charcoal making machines varies depending on factors such as brand, model, output and technical level. In the Kolkata market, the price of a basic charcoal making machine is usually around $140,000, while the price of a higher-capacity and more automated model is between $200,000 and $400,000.

Generally speaking, low-output charcoal making machines are usually more economical and suitable for small charcoal production lines. For large-scale production factories, efficient and highly automated charcoal making machines may be more expensive, but their long-term savings in labor costs and energy consumption will be more advantageous.

Equipment specifications and capacity: Different models of charcoal making machines have different abilities to process raw materials, which directly affects the price range. High-yield and high-efficiency machine is usually more expensive, but can greatly improve production efficiency and reduce unit costs.

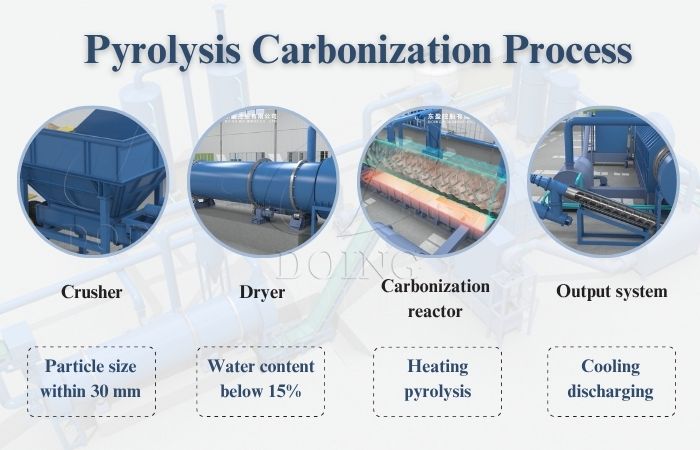

Automation: Some charcoal making machines are equipped with advanced automation technology, which can reduce manual intervention and improve production stability, so equipment with more functions is usually more expensive. DOING charcoal making machine has close connection between each section of equipment from feeding, crushing, drying, carbonization to the final unloading and pressing, which can achieve full continuous operation and greatly reduce labor input costs.

Each section of DOING charcoal making machine process

Each section of DOING charcoal making machine process

Brand and quality: There are many brands on the market that provide charcoal making machines. Equipment from well-known brands usually provides better after-sales service and technical support, such as installation guidance, operation training and regular maintenance, so this will also affect the overall price of charcoal making machines in Kolkata, India.

Raw materials and equipment design: Equipment manufacturing materials, such as the choice of pyrolysis furnace materials and machines with mature technical designs will result in higher prices, but it also means that the durability and production efficiency of the charcoal making machine are more guaranteed.

When purchasing a charcoal making machine in Kolkata, companies should choose the right equipment based on their production scale, budget, and required production efficiency. Small companies can choose equipment with smaller output and relatively cheaper prices, while large-scale production companies should consider equipment with high automation and strong production capacity. We at DOING can provide a variety of options from small and medium-sized to industrial-grade charcoal making machines for the Indian region. In addition, our charcoal making machines have many equipment advantages with more than ten years of global professional experience:

Advantages of DOING charcoal making machine

Advantages of DOING charcoal making machine

DOING charcoal making machines can efficiently process 1-5 tons of raw materials per hour and run continuously 24 hours a day, so they can realize continuous feeding, continuous carbonization, continuous charcoal production and other production processes, greatly improving production efficiency, and are ideal for large-scale production. We can customize according to different processing needs to maximize production efficiency while reducing labor costs.

Our charcoal machine adopts an advanced PLC automation control system, which requires very little manpower (usually only 2-4 workers) to achieve smooth operation. By automatically controlling the temperature and controlling the discharge, high-quality charcoal can be produced to meet market demand.

PLC automation control system for charcoal making machine

PLC automation control system for charcoal making machine

The entire equipment is heated by the syngas produced during the carbonization process. DOING's patented design significantly reduces fuel consumption during the carbonization process, thereby reducing operating costs and improving profitability. Our charcoal making machine integrates advanced emission control systems (cyclone separators, spray towers, etc.), effectively reducing harmful gases and pollutants (smoke, odor, dust), ensuring compliance with Indian and international environmental regulations (such as CPCB specifications).

Key components such as the carbonization furnace used in DOING charcoal making machines are made of industrial-grade Q345R boiler steel plates or stainless steel, which have excellent strength and corrosion resistance. This structure ensures the reliability of the equipment under the harsh conditions of Kolkata, minimizes maintenance downtime, and significantly extends the service life of the equipment (more than 5-8 years).

DOING charcoal making machine with high quality manufacturing materials

DOING charcoal making machine with high quality manufacturing materials

If you are looking for a charcoal making machine suitable for use in the Kolkata area of India, please feel free to contact us. Due to the different raw material types, output requirements and site conditions of each customer, we recommend that you contact our professional team to obtain targeted Kolkata charcoal making machine price plans. Our professional consultants can recommend the most suitable equipment configuration based on your specific situation.

contact us

CONTACT US