To solve the problem of used tyres waste plastic and waste rubber in a green way, instead of landfill or burning.

With many years exploring and conquering ,Henan Doing productiong waste plastic continuous pyrolysis plants is feeding in every second and minute,automatic ejecting wastes residue,fuel product day and night.

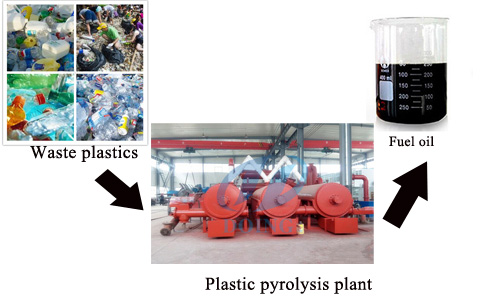

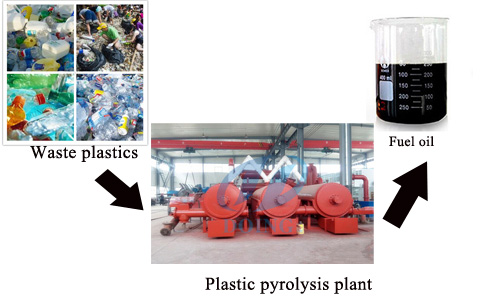

Waste plastic continuous pyrolysis plants

Doing waste plastic continuous pyrolysis plants is equipped with an automatic feeding system and two sealed discharging systems, which makes it easy to operate. It not only can dispose 10-100 tons of waste plastics per day, but also can work continuously for 24 hours per day without a stop. These latest designs make it popular among many customers.

Waste plastic continuous pyrolysis plants

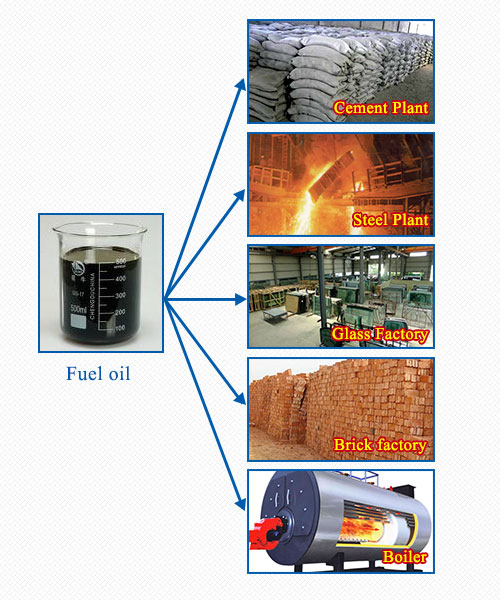

When using waste plastic continuous pyrolysis plants to dispose waste plastics, the pre-treated plastics will firstly be conveyed to the moving horizontal pyrolysis reactor through feeder system. Then the plastics will take a series of pyrolysis reactions under the action of catalyst. Finally we can get pyrolysis oil and carbon black. Both of them are available energy. For example, the pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. The carbon black can be used for making construction bricks with clay, or used as fuel.

The raw material of waste plastic continuous pyrolysis plants is waste tyre ,waste plastics,waste rubber .

Waste plastic continuous pyrolysis plant can process raw material

Oil rate of different plastics:

General Plastics: PET is not suitable (cannot be recycled).

PVC: Such as some of the films, cables, floor, pipes, windows, etc. These are not suitable (It’s acidic and will corrode the machine).

PE: Such as some films, diaphragms, film membrane, bottles, electrical appliances isolation materials, reticule, water pipes, oil drum, drink bottle, calcium feeding-bottle, milk bottle, some daily necessities, etc. The oil yield is 95%.

PP: Such as some thin films, plastic ropes, plastic crockery, plastic basin and barrel, furniture, woven bag, bottle cap, vehicle bumpers, etc. The oil yield is 90%.

PS: Such as some electrical appliance, stationery, cup, food container, household appliances shells, electric accessories, foam products, toys, etc. The oil yield is 90%.

ABS (Engineering plastics): about 40%

Pure white plastic cloth: about 70%

Bags of instant noodles: about 20%

Paper-mill waste: wet 15-20%, dry 60%

House hold garbage: 30-50%

Pure plastic cable skin: 80%

Pure clean plastic bags: more than 50%

General Rubbers:

Big truck tires: 45%

Small car tire and bike tire: about 35%

Rubber electric cable and shoe sole: about 35%

Mixture shoe sole: about 30%

Sport shoes: 20%-30%

Waste chemical fiber carpet: more than 30%

PMMA: 40%