Features

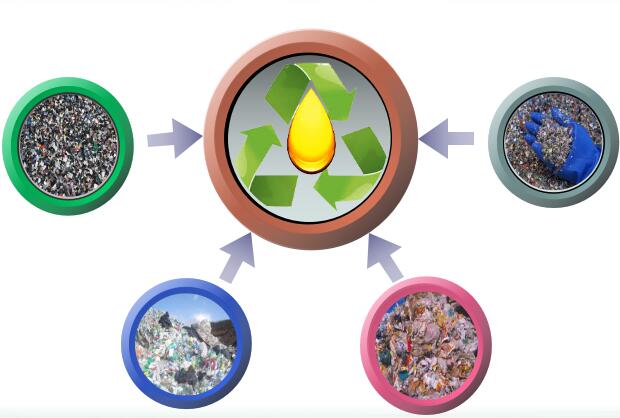

Waste plastic

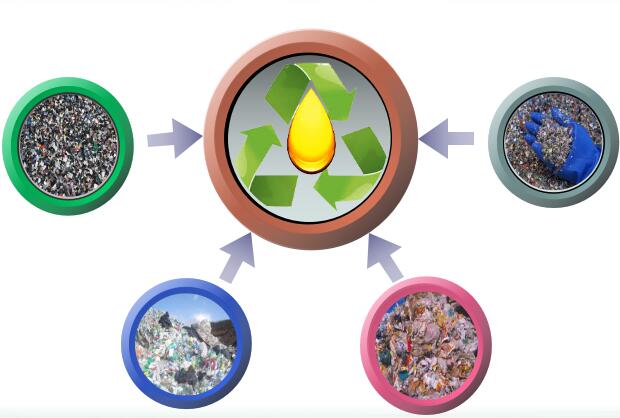

Waste plastic recycling to fuel oil plant can reduce the volumes of the waste products and help human protect the environment. And the plastic has been one of the most common materials since the beginning of 20th century because of its durability, low cost and light weight. Plastic makes up around 30% of all rubbish collected. This includes plastic bottles, containers, plastic wrap, packaging, electronic goods, car body parts, etc. Because the plastic is slow to degrade, this kind of waste becomes a problem for many people. As we all know, plastics are not only pollute the lands, waterways and oceans, but also affect the marine animals and humans, leading to the metabolic disturbance. So, solving the plastic pollution has become the imminent thing and is the primary task for people.

Waste plastic recycling to fuel oil plant

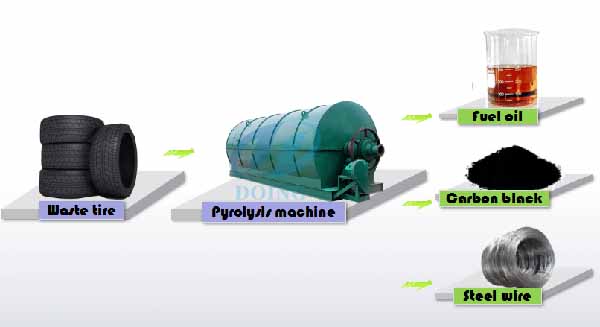

Waste plastic recycling to fuel oil plant is very popular in recent days, it can create wealth and solve environmental pollution. In most countries people handle waste tires and plastic with landfill or burning. But it causes serious pollution to environment and could probably lead to fire disaster or disease spread. By contrast, waste plastic recycling to fuel oil plant is a green way for waste management. Waste plastic recycling to oil plant can convert waste plastic to fuel oil and carbon black.

Waste plastic recycling to fuel oil plant some information

Waste plastic recycling to fuel oil plant

Henan DOING Mechanical Equipment Co.ltd is a leading manufacturer specialized in large and medium-sized oil-related machineries, including waste plastic recycling to fuel oil plant, and waste tire recycling pyrolysis machine to get fuel oil, waste oil/black oil refinery machine to get diesel oil.

1. End product percentage: plastic oil 85%-90% for PP, PE, PS, ABS.

2. Delivery time: the delivery time shall be 25days more or less after get the advance payment.

3. Warranty and machine life: We guarantee the complete machine 1 year, the reactor service life can be 6-8 years.

4. The machine Raw material: Q245R Boiler plate with 16mm thickness.

5. The machine installation: we will send engineer to buyer’s place when getting the machine. The engineer mainly installs the machine and training your workers. Until the machine can running well.

6. Port (China): Qingdao port or shanghai port.

Technical Data

Waste plastic recycling to fuel oil plant technical data

|

Technical parameter of waste plastic recycling to fuel oil plant |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste plastic |

Waste plastic |

Waste plastic |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about waste plastic recycling to fuel oil plant |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

Application

Waste plastic recycling to fuel oil plant

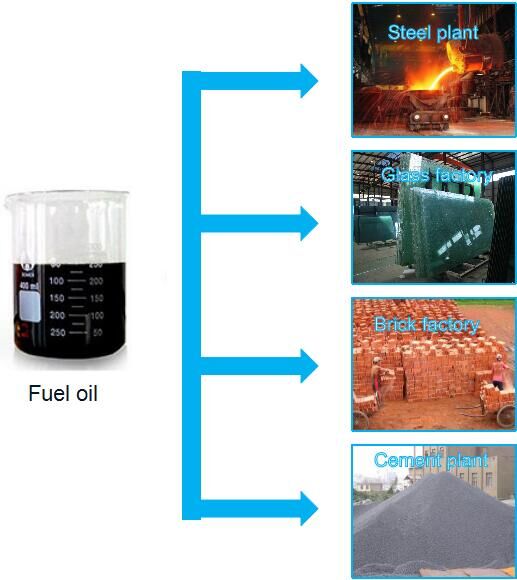

Fuel oil

Fuel oil application

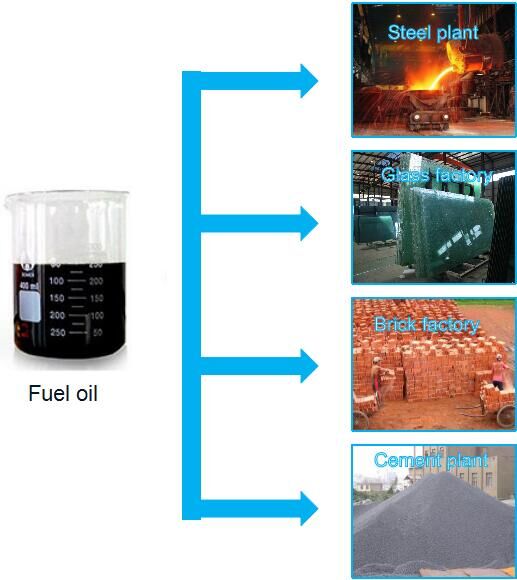

This oil product is a kind of crude fuel oil, which can be used for industrial heating used in any fuel needed industrial factories, such as cement plant, steel mill, glass factory, brick factory, boiler used factory, etc. Or can be refined to diesel, directly used in diesel burners, generators, heavy trucks, agricultural machinery, and mix with normal diesel used for cars.

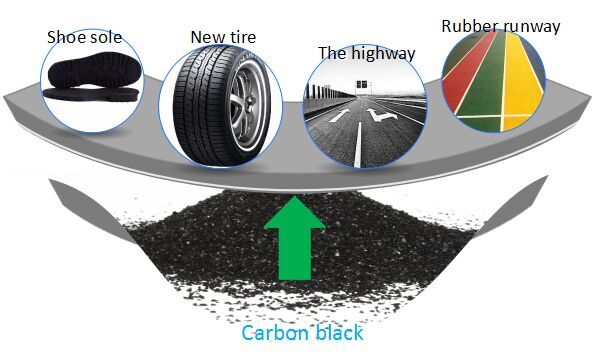

Carbon black

Carbon black application

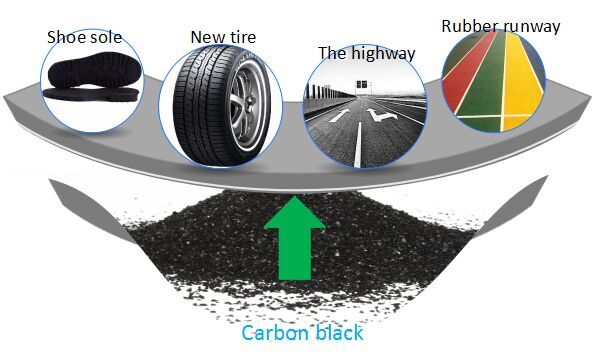

Carbon black produced from this system is crude powdery material, which can be directly sold to cement factory mix with cement. Or made into briquettes used for heating, just like coal. Or grinded into fine powder used for making paint and printing ink.