WhatsApp

WhatsApp

In March, 2025, Henan Doing Company successfully installed and initiated the commissioning of a 15 TPD batch waste plastic pyrolysis plant at a plastic pellet manufacturing facility in India. This set of pyrolysis machine transforms waste plastic pellet waste into high-quality fuel oil and carbon residue, achieving dual goals of environmental protection and resource recovery.

Waste plastic pellet pyrolysis plant installed in India

Waste plastic pellet pyrolysis plant installed in India

Waste plastic pellet pyrolysis plant installed in India

Waste plastic pellet pyrolysis plant installed in India

The client, a leading plastic pellet producer in India, generates significant amounts of irregular, non-recyclable plastic pellets during daily production. Disposing of these pellets conventionally would lead to resource waste and environmental hazards . After extensive market research and technical evaluations, the client chose Henan Doing Company as the batch waste plastic pyrolysis plant manufacturer.

DOING plastic pyrolysis plant stands out for its cost-effective investment, compact footprint and flexible operation , tailored to their scale production needs.

DOING plastic pyrolysis plant for sale in India

DOING plastic pyrolysis plant for sale in India

Our team designed and delivered a set of plastic pyrolysis plant capable of processing 15 tons of plastic pellets daily. Key features include:

Advanced Thermal Cracking Technology: Optimized heating systems and control system to ensure rapid pyrolysis at 280–400°C, maximizing oil yield. It can effectively convert plastic waste into fuel oil (more than 70% yield for PP/PE plastic pellet), carbon black residue and syn-gas.

Closed-Loop Pyrolysis Process: Multi-stage gas filtration and dust removal systems to minimize emissions, ensuring compliance with international environmental standards.

From pyrolysis plant solution customization, machine fabircation and shipment to on-site assembly, our engineers provided full technical support, guiding the client’s local team through installation, pipeline connection, and system calibration.

Waste plastic pyrolysis plant delivered to India

Waste plastic pyrolysis plant delivered to India

Waste reduction: this 15TPD plastic pyrolysis plant installed in India can reduce the waste reduction in plastic pellet landfilling.

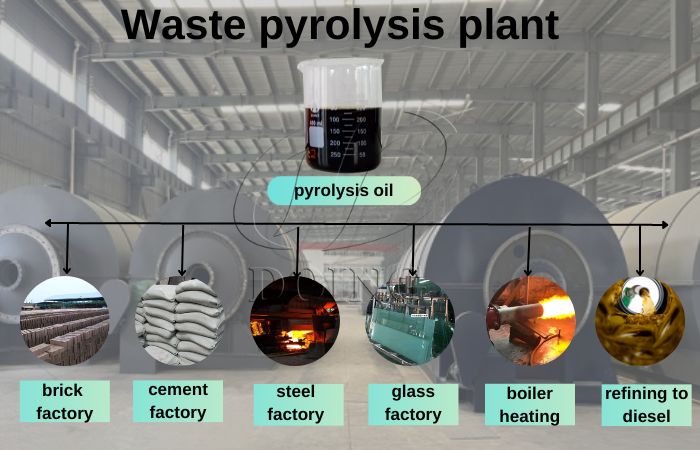

Energy Recovery: Produced fuel oil replaces fossil fuels, reducing CO emissions and offering valuable heating fuel for heavy insudtries, such as steel/cement/brick/china production factories and heavy oil power plant.

Applications of plastic pyrolysis fuel oil

Applications of plastic pyrolysis fuel oil

Economic Benefits: Lower operational costs and revenue from fuel oil and carbon residue sales.

By transforming plastic waste into valuable resources, pyrolysis technology empowers industries to align with sustainability goals while achieving operational excellence. Beyond this kind of batch pyrolysis plant project installed in India, we Henan Doing Company also offer:

Semi-Continuous Pyrolysis Plants: Ideal for medium-scale operations, balancing efficiency and cost.

Fully Automated Continuous Pyrolysis Plants: Designed for 24/7 industrial applications with minimal manual intervention.

For inquiries about DOING pyrolysis plant or customized solutions compatible with versatile feedstocks like plastic waste, tire crumbs, oil sludge, coal tar oil and drilling cuttings, contact us today

contact us

CONTACT US