WhatsApp

WhatsApp

In May 2024, Henan Doing Company was proud to announce the successful installation and commissioning of its 30 tons/day tire oil production pyrolysis plant in Uzbekistan. This waste to fuel project highlights our commitment to providing sustainable energy solutions globally.

Waste tire oil production pyrolysis plant installed in Uzbekistan

Waste tire oil production pyrolysis plant installed in Uzbekistan

The Uzbek customer, a prominent brick factory operator. Uzbekistan had recently implemented new policies restricting natural gas consumption, which severely impacted their factory’s production and profitability. This created a pressing need for an alternative, reliable, and cost-effective fuel source to ensure uninterrupted operations of their brick factory.

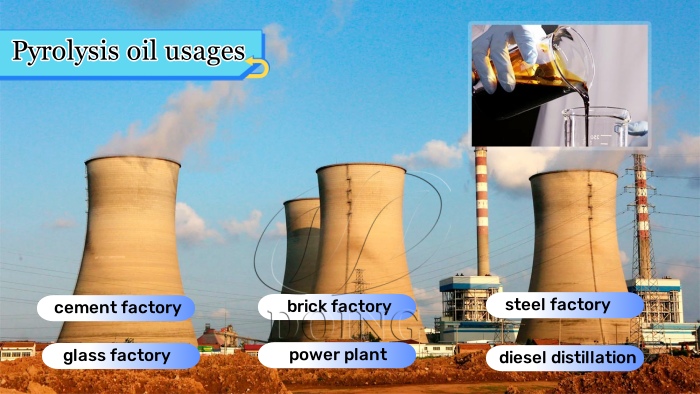

Fortunately, DOING tire oil production pyrolysis plant, leveraging advanced pyrolysis technology, offered an ideal solution. Specifically, the tire oil produced from waste tires through a low-temperature pyrolysis process boasts a high calorific value, making it an excellent alternative fuel for various industrial applications such as boilers, steel mills, cement plants, ceramic facilities, and, crucially, brick factories. This perfectly aligned with the Uzbek customer’s fuel requirements.

Pyrolysis oil usages as alternative heating fuel for brick factory

Pyrolysis oil usages as alternative heating fuel for brick factory

Based on a thorough assessment of the Uzbek customer’s operational requirements and the specific needs of their brick factory, Henan DOING’s project management team strategically recommended a solution featuring two sets of 15 tons/day batch tire oil production pyrolysis plants operating in series.

The main configuration of each tire oil product pyrolysis plant:

Automatic Feeder: A 50-ton hydraulic thrust mechanism facilitates automated feeding, ensuring efficient and continuous feeding of waste tires.

Automatic feeder for tire oil production pyrolysis plant

Automatic feeder for tire oil production pyrolysis plant

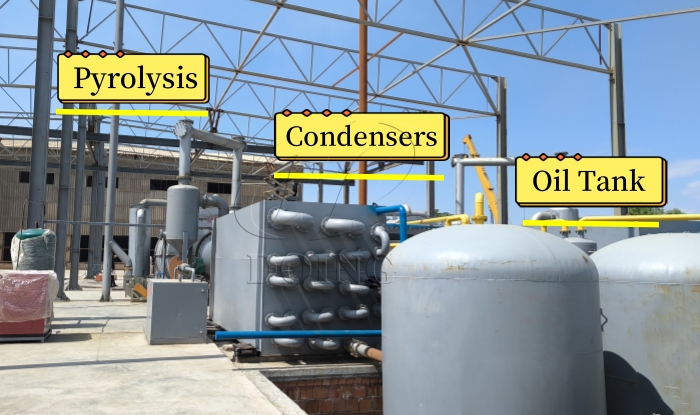

Pyrolysis Reactor (Cracking Furnace): The core component of the tire oil production pyrolysis plant, where waste tires undergo thermal decomposition (pyrolysis) at controlled temperatures to yield valuable oil and gas.

Buffer Tank: Designed to manage the flow of pyrolysis oil and gas, preventing rapid surges and ensuring sufficient time for condensation. It also acts as a preliminary separator, settling carbon black impurities to protect downstream condensers and pipelines within the tire oil production pyrolysis plant.

Tire Oil Condensation System (Water Tank Condenser): Utilizes a circulating cooling water system to efficiently condense the pyrolysis oil and gas generated by the tire oil production pyrolysis plant into liquid fuel oil.

Waste tire oil production pyrolysis line equipment configuration

Waste tire oil production pyrolysis line equipment configuration

Negative Pressure Safety Device: Maintains a slight negative pressure within the tire oil production pyrolysis plant reactor system, ensuring safe operation by continuously drawing out residual oil and gas for further condensation, preventing pressure buildup and maximizing oil recovery. The recovered oil gas is safely routed back into the condensation system.

Exhaust Gas Treatment (Desulfurization and Deodorization Device): This crucial component processes non-condensable exhuast gases, removing harmful elements like hydrogen sulfide. The purified syn-gas is then safely recycled back to the pyrolysis reactor of the tire oil production pyrolysis plant as supplemental fuel, significantly reducing operational costs and ensuring environmental compliance in Uzbekistan.

Dust Collector (Water Film Dust Collector): An integral part of the emission control system, effectively purifying exhaust gases and significantly reducing particulate matter emissions from the entire tire oil production pyrolysis plant.

Uzbekistan tire oil production pyrolysis plant installation site

Uzbekistan tire oil production pyrolysis plant installation site

This comprehensive 30 tons/day tire oil production pyrolysis plant is designed for high automation and impressive oil yield. Capable of processing 30 tons of waste tires daily, with an estimated tire oil yield of 45%, the plant is projected to produce 13-14 tons of high-quality pyrolysis oil per day. This output is more than sufficient to meet the daily fuel demands of the Uzbek customer’s brick factory, providing them with a reliable and independent energy supply.

The successful commissioning of this tire oil production pyrolysis plant in Uzbekistan, not only provides a sustainable and reliable fuel source for the client’s brick factory, but also champions the circular economy by transforming waste tires into valuable resources. This project showcases substantial economic benefits for the client and considerable environmental advantages for the region of Uzbekistan by reducing waste and promoting cleaner energy alternatives.

contact us

CONTACT US