WhatsApp

WhatsApp

Common waste oil recycling ways include oil-water separation, biological treatment, thermochemical treatment, marine recycling and re-refining. Among them, waste oil refining is one recommended way for waste oil recycling. Because it is more environmentally friendly than other ways and can realize resource reuse.

Waste oil refining mainly uses refining plants to convert waste oil into diesel. After proper processing, the diesel got from waste oil can be used for diesel machinery. So what is the waste oil refining recycling process? Here will introduce the process of DOING waste oil refining plant.

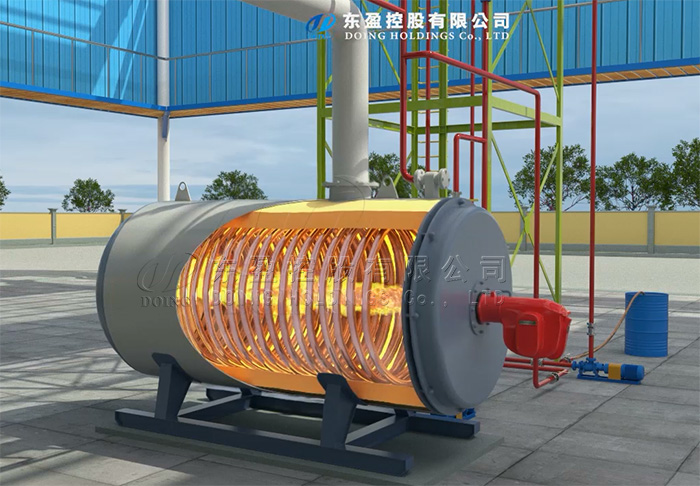

Pump the waste oil into the reactor through the oil pump machine, then start the thermal oil preheating system. After the thermal oil fills the entire system, start heating the reactor.

DOING dual-heating system

DOING dual-heating system

As the temperature of the reactor continues to increase, the waste oil gradually boils and vaporizes. At the same time, as the waste oil heats up, the impurities in it will continue to settle, and the remaining oil and gas will enter the catalytic tower.

DOING's double-layer structure catalytic tower can remove colloids and waxes from oil and gas. After degumming and dewaxing, the oil will become clearer.

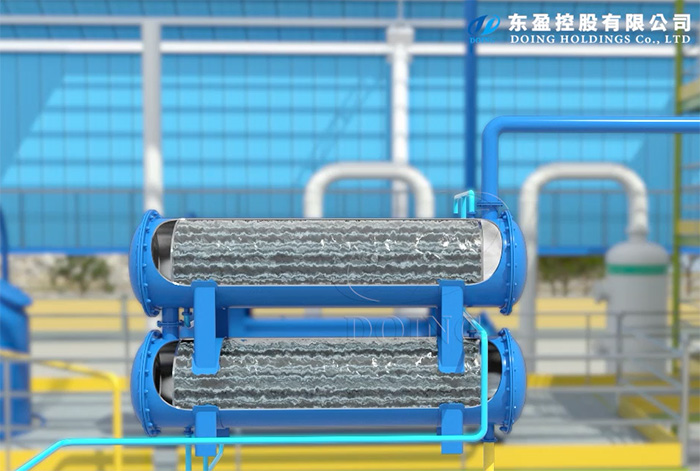

The oil gas will enter the condensation system after a catalytic reaction. The oil and gas pass through the circulating cooling water in the condensation system to be cooled down, then get primary diesel oil and it will be collected into the oil tank.

The condensation process of waste oil refining

The condensation process of waste oil refining

For now, diesel has got a darker color compared with standard diesel. In order to get a better quality diesel, the next step of decoloring and purification system was needed.

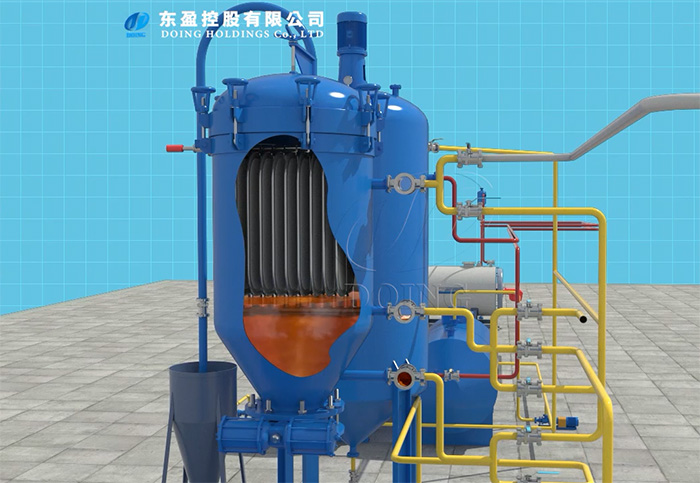

Introduce the diesel in the oil tank into the clay decolorization system, and then enter the plate filter and bag filter to filter out the clay, and you will get a clear and translucent diesel.

The decolorization process of waste oil refining

The decolorization process of waste oil refining

After the process of refining, there is no oil content in the residues and these will be discharges automatically.

The flue gas enters into the desulfurization and dust removal purification system for treatment. DOING's desulfurization and dust removal purification system is an environmental protection device, which is filtering the dust and removing some little sulfide. Making sure that the emission is friendly to the environment and meet the policy requirements of each country.

The above is an introduction to the DOING waste oil refining process. Henan DOING's waste oil refining plant has different models and processing capacity, on the basis of the latest design of refinery machine, which is getting very popular with its high efficiency and safety.

DOING waste oil reining plant

DOING waste oil reining plant

In a word, the refining plant is the suitable and best way for you to recycle waste oil like waste engine oil, used motor oil, old lube oil, tire plastic pyrolysis oil, crude oil, etc. Any unclear information, please always feel free to contact us. Get free quote of our waste oil refining plant, welcome to leave us a message via the message box below.

contact us

CONTACT US