WhatsApp

WhatsApp

Pyrolysis reactor, also called pyrolysis machine or pyrolysis system, which plays an important role in recycling waste tires, plastics, oil sludge, etc. to fuel oil.

In general, the common cost of pyrolysis reactor is between 11,000 dollars and 70,000 dollars, which is affected by the following factors:

1. Processing capacity of pyrolysis reactor

The common processing capacity of pyrolysis reactor is 100/500KG and 1/5/10/12/15 tons per day; If you require a larger processing capacity, DOING can provide you with customized options, such as 30/40/50 tons per day. However, the larger the processing capacity, the higher the cost.

2. Types of pyrolysis reactor

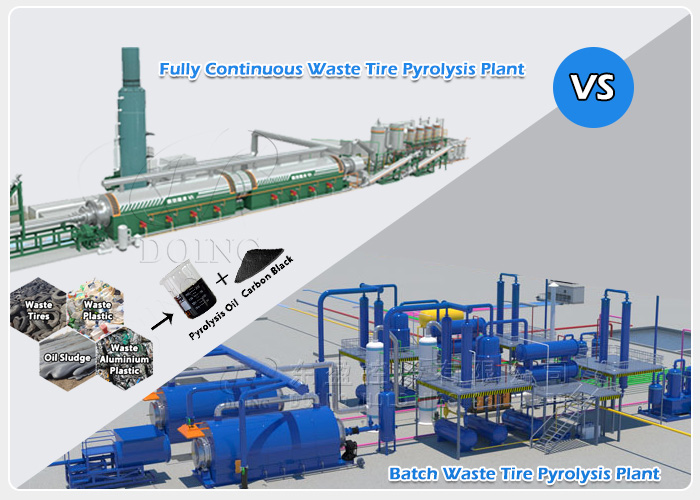

The common type of pyrolysis reactor is the batch type, whose cost is relatively cheap; while fully continuous pyrolysis reactors are more expensive due to their higher work efficiency and larger processing capacity, costing more than 400,000 dollars.

DOING Batch and fully continuous pyrolysis reactors for sale

DOING Batch and fully continuous pyrolysis reactors for sale

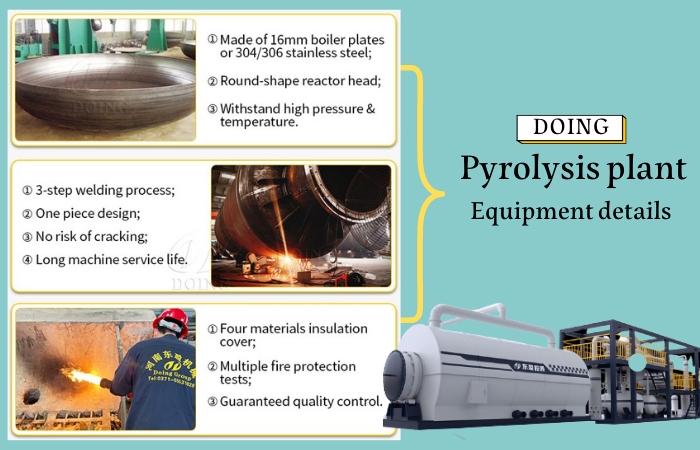

3. Materials and technology of pyrolysis reactor

As we all know, the materials and technology of pyrolysis reactor affect its working efficiency, service life, working safety, etc. So the better the materials and technology the pyrolysis reactor adopts, the higher the cost will be. Take DOING as an example, while manufacturing, DOING uses the Q345R and Q245R materials, which can withstand high temperature and pressure to enhance working safety and service life; and the newly designed fully continuous pyrolysis reactor adopts the fully automatic PLC control system to improve its working efficiency, which all increase the cost of pyrolysis reactor.

Advantages of DOING pyrolysis reactor

4. Optional configurations of pyrolysis reactor

For batch-type pyrolysis reactor, DOING researched auto-feeder to enhance working efficiency and reduce labor cost; and if you choose the fully continuous pyrolysis reactor, we also have the waste tyre to rubber powder device to pretreat waste tyres; what's more, in order to meet the exhaust emission standards of different regions, DOING also has the dedusting system and tail-gas purification system for your choice. Of course, these optional configurations will increase your cost while bringing you benefits.

5. Manufacturers of pyrolysis reactor

Various manufacturers will offer customers different cost quotes according to their own material cost, labor cost, technology cost, etc. So some agent factories and middlemen will offer relatively higher costs. While DOING-the top pyrolysis reactor manufacturer in China, has our own manufacturing factory, we can provide you with relatively reasonable quotations.

DOING professional technical team

So far, thousands of customers have ordered pyrolysis reactors from DOING Company and given great feedback. So if you are interested in waste recycling or want to invest in pyrolysis reactor, DOING Company will be your best choice, welcome for consultation!

contact us

CONTACT US