WhatsApp

WhatsApp

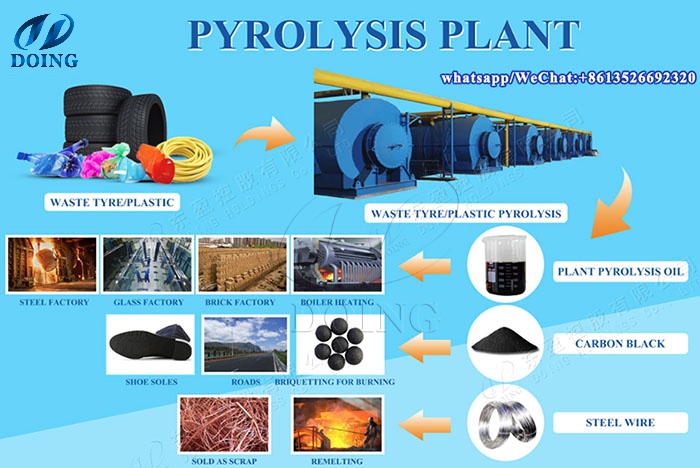

Pyrolysis oil produced by pyrolysis plant at high temperature is a high calorific value renewable fuel oil. The tire pyrolysis oil calorific value is 10300kcal, the density is 0.91-0.93g/cm3, and there is no water and no mechanical impurities. The calorific value of plastic pyrolysis oil is about 9700-10000kcal. Due to the complexity of plastics, the calorific value fluctuates relatively large. However, both tire pyrolysis oil and plastic pyrolysis oil are good industrial fuel oils.

Due to the high calorific value of pyrolysis oil, it is a good industrial heating fuel, and it is mostly used for heating in boiler factories, cement factories, glass factories, ceramic factories and steel factories; it is used for power generation of heavy oil generators; it can also be further refined by waste oil distillation plant and processed into diesel oil, which is used in diesel combustion engines, generators, agricultural machinery, heavy machinery, such as cruise ships, tractors, etc.

Tire plastic pyrolysis oil and carbon black applications

Tire plastic pyrolysis oil and carbon black applications

Nowadays, with the rise of international oil prices, the influence of coal industry control and high cost of electric heating, more and more enterprises that need industrial fuel heating have begun to rely on fuel oil such as tire pyrolysis oil and plastic pyrolysis oil to reduce energy costs of enterprises and improve economic benefits. Therefore, the market and sales of fuel oil produced waste tires/plastic pyrolysis plant are very good.

In addition topyrolysis oil, the carbon black extracted from pyrolysis plant also has a high calorific value of combustion, which can reach 7000 kcal, which is similar to the combustion value of coal. Therefore, after the carbon black is pressed into balls by briquetting machine, it can completely replace coal for industrial heating, and has high industrial utilization value.

This is why more and more bosses want to set up waste tire/plastic pyrolysis plant projects. If you want to do related projects, one of the most important preparations is to choose the appropriate pyrolysis machines.

Different types of batch continuous pyrolysis machine for sale

Different types of batch continuous pyrolysis machine for sale

The waste tire plastic pyrolysis machines of Henan Doing Company is mainly divided into four types: skid-mounted type, batchtype, semi-continuous type and full-continuous type according to different working methods. The process principles of these four types of equipment are basically the same. The main difference lies in the processing capacity of the equipment, the degree of automation, the design of feeding and slag discharge, etc. Our pyrolysis machines are sold well in more than 100 countries and regions around the world, and highly praised by many new and old customers.

Pyrolysis plant project cases installed by DOING pictures

Pyrolysis plant project cases installed by DOING pictures

Our pyrolysis machine adopts external heating, micro-negative pressure, oxygen-poor thermal pyrolysis technology. The pyrolysis reactor body is sealed, and the furnace door is made of high-temperature sealing materials, so as to ensure that the gas does not leak out during the production process. It can improve efficiency, save energy and reduce consumption. And at the same time, it can eliminates unsafe hidden dangers and fugitive emissions caused by gas leakage. In addition, DOING pyrolysis machine is equipped with comprehensive environmental protection facilities and pollution prevention and control measures to meet different countries standards. Welcome to consult us if you are interested!

contact us

CONTACT US