WhatsApp

WhatsApp

The tire to oil recycling line, also known as a waste tire pyrolysis plant, converts scrap tires into valuable products like fuel oil, carbon black, and steel wire through a thermal decomposition process. This technology helps manage tire waste while generating revenue from byproducts. For those exploring this business, understanding the costs is essential.

The price of a tire to oil recycling line is not a fixed figure; it's a dynamic calculation influenced by several critical factors. These include:

Machine Capacity: The daily processing volume of raw materials directly correlates with the size of the plant, thus impacting the cost.

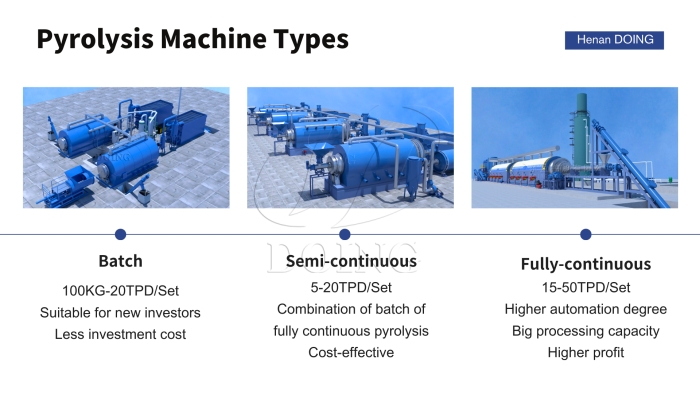

Machine Type/Configuration: Different operational modes (batch, semi-continuous, fully continuous) offer varying levels of automation, efficiency, and initial investment.

DOING tire to oil recycling line types

Environmental Emission Standards: Local regulations regarding emissions (such as sulfur content or particulate matter) necessitate specific, often more advanced, treatment systems, which add to the overall cost.

Customer-Specific Requirements: Customization for specific raw material characteristics, desired output quality, or unique site conditions can also influence the final price.

Let’s break down the general price ranges based on common machine capacities and types.

For individuals or businesses looking to validate the economic feasibility of waste tire pyrolysis with their specific local feedstock, small-capacity pyrolysis plants are a prudent starting point.

Capacity: Typically ranges from 100 kg to 1ton per day.

Machine Type: skid-mounted, making them relatively portable and quicker to set up for initial trials.

Investment Suitability: These are ideal for new entrants or those with limited initial capital who prioritize understanding oil yields and operational parameters before committing to larger investments. Testing oil yield (typically 40-45% from tires) helps confirm profitability without high upfront costs. They're also practical for research or small workshops, as they require minimal space and fewer operators. Once feasibility is proven, investors can transition to larger setups.

Estimated Price Range: Approximately 15,000 to 21,000 USD.

Small scale tire to oil pyrolysis recycling line

Medium-capacity lines strike a balance between processing volume and initial capital outlay, making them a popular choice for many businesses. This category offer two options: batch pyrolysis and semi-continuous pyrolysis lines.

Capacity: Commonly available in daily processing capacities of 5 tons - 20 tons.

Machine Types:

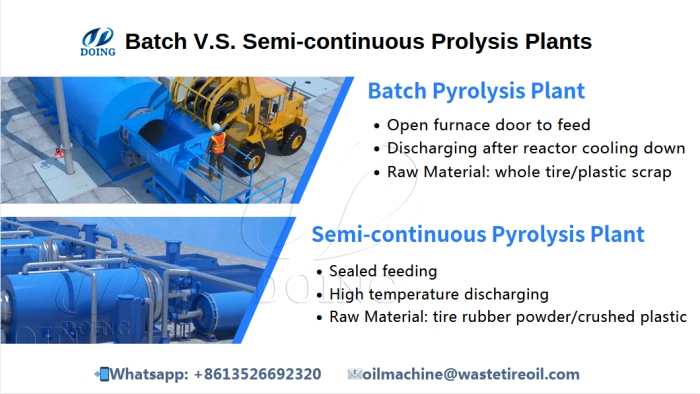

Batch Tire to Oil Recycling Line: This line operates in batches, requiring shutdown after each processing cycle (feeding, pyrolysis, slag discharge). It features a compact structure, low investment cost, and is suitable for small to medium scale production or scenarios with variable raw materials. It offers high operational flexibility and typically lower initial costs, but requires relatively high levels of manual intervention.

Semi-Continuous Tire to Oil Recycling Line: Semi-continuous pyrolysis line strikes a balance between batch and fully continuous operation. It achieves continuous operation of feeding and cracking, with significantly higher thermal efficiency and automation than batch systems, while its investment cost and technical requirements are much lower than those of fully continuous systems. It is an ideal compromise for those seeking stable mass production with limited budgets.

Batch and semi-continuous tire to oil recycling line

Investment Suitability: Suitable for businesses with moderate capital who require a consistent processing volume to achieve economies of scale. Popular capacities like 10tpd and 15tpd are well-established in the market.

Configuration Options:

Standard Configuration: Offers reliable operation and essential features for efficient pyrolysis, typically at the lower end of the price spectrum for this capacity range.

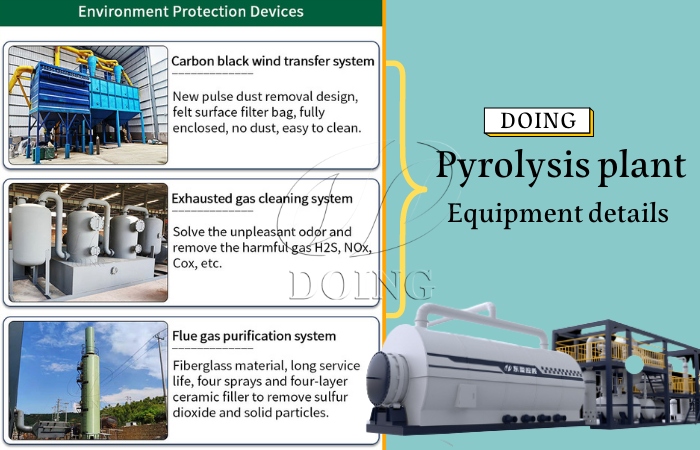

High Configuration: Includes advanced flue gas treatment systems (e.g., desulfurization towers, enhanced dust removal devices) to meet stringent local environmental emission standards. This option represents a higher investment but ensures regulatory compliance.

DOING tire to oil pyrolysis line environment protection devices

Estimated Price Range: 60,000 to100,000 USD. The price varies significantly based on whether it’s a batch or semi-continuous system and the level of environmental protection equipment included.

For enterprises aiming for significant production volumes and operational efficiency, large-capacity, fully continuous tire to oil recycling line are the solution.

Capacity: Available in daily processing capacities of 20 tons to 50 tons per day.

Machine Type: Fully Continuous Pyrolysis Line. This line are designed for extended operational periods, often running for 45-60 days without interruption from feeding to carbon black discharge. They typically integrate PLC control systems to minimize manual labor and optimize production.

Investment Suitability: This type is well-suited for large-scale waste management operations, regions with abundant tire waste, and companies prioritizing high throughput and reduced operational manpower.

Estimated Price Range: 650,000 to1,000,000 USD. The higher end of this range reflects advanced automation, robust environmental controls, and integrated waste heat recovery systems.

DOING fully continuous tire to oil pyrolysis recycling line

While capacity and machine type are primary cost drivers, other elements play a role:

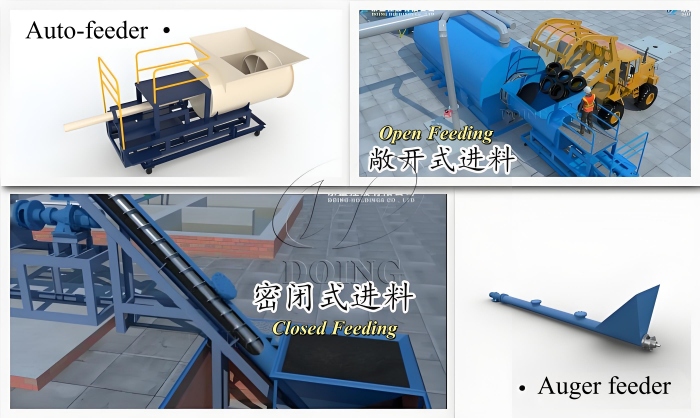

Equipment Configuration: For equipment with the same capacity, different furnace types and materials, levels of automation (e.g., automatic feeding systems), whether pretreatment (e.g., rubber powder equipment) is included, whether flue gas treatment systems (desulfurization, dust removal, flue gas monitoring) are included, and product processing (e.g., carbon black briquetting equipment) all significantly impact price.

DOING tire to oil pyrolysis recycling line feeding systems

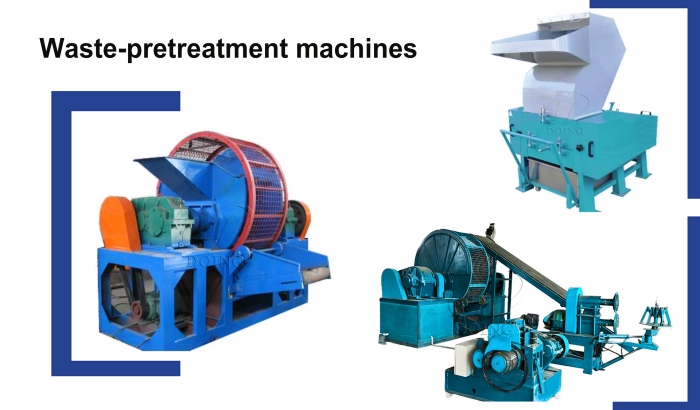

DOING tire to oil pyrolysis recycling line pre-treatment machines

Carbon black refining machine

Customer Needs: The combination of skid-mounted, batch, semi-continuous, and fully continuous systems, the degree of automation, data acquisition and monitoring software, and after-sales maintenance services all affect total cost.

Installation and Commissioning: Site conditions, foundation engineering, installation time, training plans, and after-sales service cycles also affect total investment.

Regional Regulations and Certifications: Emission standards, environmental certifications, and import tariffs affect equipment configuration and price.

Return on Investment and Operating Costs: A preliminary return on investment analysis needs to be conducted, taking into account factors such as electricity, fuel, maintenance, wear parts, labor costs, and capacity utilization.

Understanding these cost factors is the first step toward a successful tire to oil recycling line. Each project has unique parameters, including local waste availability, market demand for pyrolysis oil and carbon black, and specific environmental regulations.

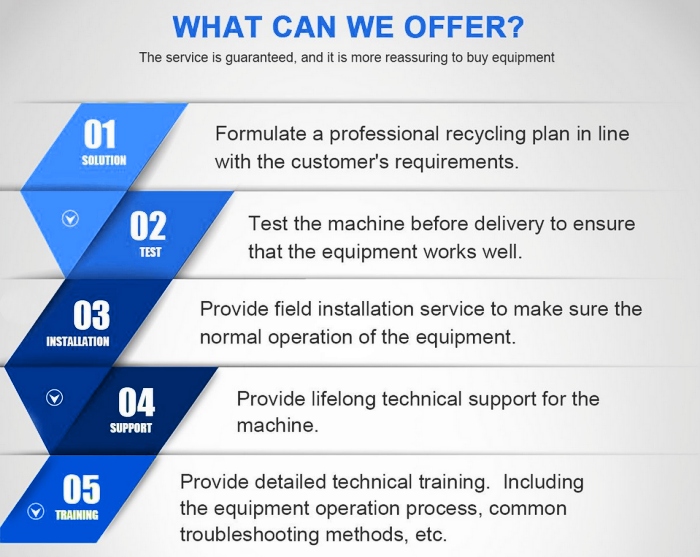

At DOING Company, we are committed to assisting entrepreneurs in navigating these complexities. We offer tailored solutions and expert advice to help you select the most suitable and cost-effective pyrolysis line based on your budget, operational goals, and local compliance requirements.

DOING tire to oil pyrolysis recycling line manufacturer

If you are considering entering the waste tire to oil recycling pyrolysis business and would like a detailed assessment of potential plant costs and operational strategies, we encourage you to connect with us. Our team is ready to provide personalized guidance to help you establish a profitable and sustainable operation.

contact us

CONTACT US