WhatsApp

WhatsApp

Vegetables, fruits and other kitchen waste can be processed by carbonization technology and converted into biochar. This type of organic waste contains rich cellulose and lignin components, and can complete pyrolysis reactions under appropriate temperature conditions. The carbonization process can convert organic matter in kitchen waste into stable carbonaceous materials. This process belongs to thermochemical conversion technology. This conversion not only solves the problem of waste disposal, reduces environmental problems caused by landfill or incineration, but also obtains valuable biochar products.

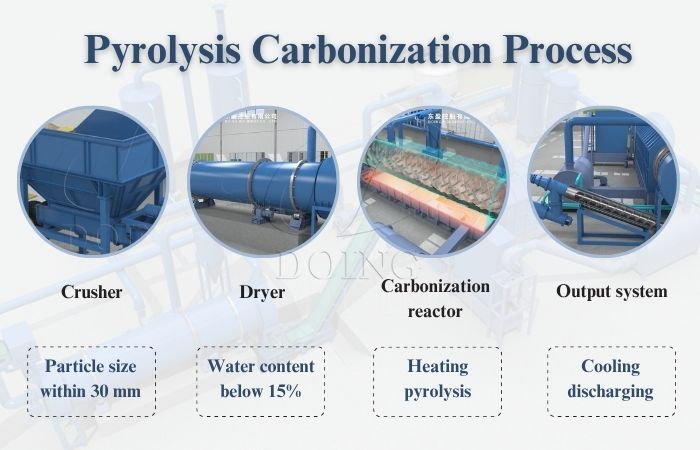

Pyrolysis refers to the process of thermally decomposing organic matter in an oxygen-deficient environment by heating (usually at a temperature of 300~700℃) to generate solid carbon (biochar), combustible gas and liquid products. The following is a detailed introduction to the key steps of kitchen waste carbonization.

First, the kitchen waste should be crushed into smaller particles, and the particle size should be ensured to be within 30 mm. This helps to reduce its volume, thereby improving the effect of uniform heating. The surface area of the crushed material increases, which can more easily contact the heat source, ensuring more uniform heat transfer during the carbonization process.

Kitchen waste pyrolysis carbonization process

Kitchen waste pyrolysis carbonization process

Next is dehydration. Kitchen waste contains a high amount of water, and it is usually recommended to reduce its water content to less than 15%. Reducing the water content not only helps to improve the carbonization efficiency, but also avoids excessive water content causing energy waste and environmental pollution during the carbonization process.

After pretreatment, the carbonization stage begins. In this process, the material is fed into the carbonization furnace and heated at high temperature to cause pyrolysis. The temperature and residence time of the carbonization furnace are important factors that determine the characteristics of the product. Usually, the temperature of the carbonization process is controlled between 300℃ and 700℃, and the residence time is generally 1 to 2 hours.

Biochar pyrolysis machine for kitchen waste

Biochar pyrolysis machine for kitchen waste

Low-temperature carbonization (below about 400℃) will produce relatively rich biochar, which is suitable for soil improvement. At this time, the biochar has smaller pores, mainly by increasing the organic matter content and water retention capacity of the soil, improving the structure and fertility of the soil. In contrast, high-temperature carbonization (above 600℃) will produce carbonized products with larger pores, which are more suitable as adsorbents and can effectively adsorb harmful substances in the air or water, such as heavy metals and organic pollutants.

The biochar generated by carbonization of kitchen waste needs to be cooled by a cooling system to ensure safe handling and storage. Generally speaking, the cooling temperature needs to be controlled below 50 degrees. The main purpose of the cooling stage is to reduce the temperature of the biochar, prevent spontaneous combustion, and ensure the quality and safety of the product. The cooled biochar has good structural stability, high energy density, and higher value.

The final products of the carbonization process of kitchen waste such as vegetables, fruits and melons mainly include biochar, combustible gas and tar. These products have broad application prospects. As an important environmentally friendly material, biochar has multiple functions such as improving soil structure, fixing carbon and reducing emissions, and adsorbing pollutants. It can effectively improve the water retention capacity of the soil, promote plant growth, and can also serve as a carbon sink to help reduce greenhouse gas emissions. At the same time, the combustible gas and tar produced during the carbonization of kitchen waste can be recycled.

Products and applications of biochar pyrolysis

Products and applications of biochar pyrolysis

In general, the carbonization process of kitchen waste not only helps to reduce the amount of waste, but also creates economic and environmental benefits through resource utilization. With the continuous development and application of carbonization technology, it is expected to play an increasingly important role in the field of waste treatment and resource recovery.

In view of the characteristics of kitchen waste, it is very important to choose the right biochar pyrolysis machine. As a professional biochar pyrolysis machine manufacturer, the pyrolysis machine provided by DOING can efficiently and stably carry out carbonization treatment of kitchen waste such as vegetables, fruits, etc. Our equipment adopts advanced pyrolysis technology to ensure efficient use of energy in the treatment process, minimize energy consumption, and achieve efficient conversion while ensuring safety.

DOING biochar pyrolysis machine for sale

DOING biochar pyrolysis machine for sale

We provide a variety of models of biochar pyrolysis machine, suitable for different scales of waste treatment needs. Whether it is small equipment or processing equipment for large commercial facilities, we can provide professional technical support and customized solutions to help customers reduce operating costs while protecting the environment. If you are interested in our machine, please feel free to consult us. We will provide you with detailed product information and technical support to help you choose the most suitable solution.

contact us

CONTACT US