WhatsApp

WhatsApp

At present, waste tire recycling regeneration projects mainly include waste tire retreading, waste tire regenerated rubber powder, and waste tire pyrolysis projects.

The retreading of waste tires does not change the general shape of the original tires, and there is no chemical reaction process, which can reduce costs and energy consumption to a certain extent. But the application scale of the retreaded tires is small, and the quality of retreaded tires cannot be guaranteed.

Reclaimed rubber powder from waste tires needs to undergo a series of treatment, such as steel wire drawing, tire cutting, grinding, etc. The obtained rubber powder is generally used in non-rubber fields such as road paving and anti-corrosion coatings.

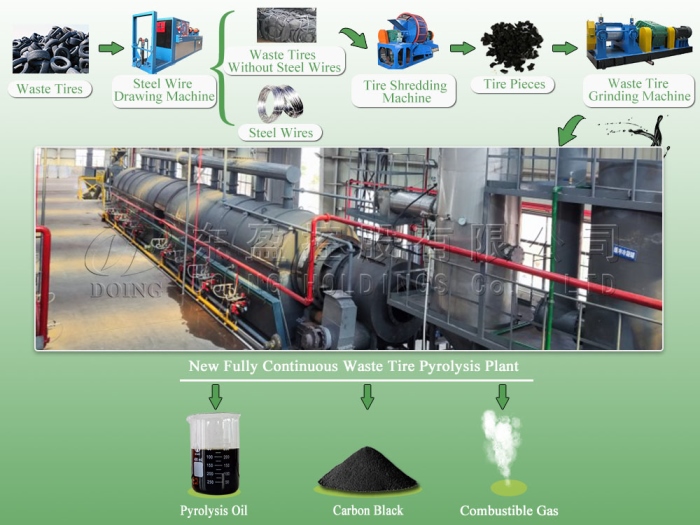

The process of waste tyres pyrolysis plant

The process of waste tyres pyrolysis plant

Retreading of waste tires, reclaimed rubber powder from waste tires only change the shape of the original tires, and cannot achieve real reduction, recycling and harmless treatment of the growing number of waste tires. In contrast, the waste tire pyrolysis way can regenerate tires into resources and energy, such as pyrolysis oil, carbon black, steel wire and combustible gas, while recycling tires in an environmentally friendly manner. It has large processing capacity, low cost, and high efficiency.

Pyrolysis of waste tires can be used as an ideal disposal method to recover various resources in waste tires to a greater extent, help tires and rubber to enter the industrial chain again, and extend the added value of products. The tire pyrolysis oil is a good industrial heating fuel, which can be widely used in iron factories, power plants, cement factories, restaurants, boiler, etc. Or you can refine the tire pyrolysis oil into diesel fuel for wide uses. The carbon black obtained from waste tire pyrolysis plant can be modified to achieve high value, and can be reused as raw materials for tires and rubber products.

The finnal product of waste tyre pyrolysis plant

The finnal product of waste tyre pyrolysis plant

In addition, the thermal pyrolysis energy consumption of waste tires is much lower than that of reclaimed rubber powder. According to data, the production of per ton of rubber powder consumes 600kW/h of electricity, while the pyrolysis of waste tires per ton/rubber consumes only 200kW/h of electricity. Therefore, the waste tire pyrolysis renewable energy project is more in line with the current long-term development trend, that's reducing energy consumption, recycling waste tires in an environmentally friendly way to seek high profits.

To learn more about investing in waste tire recycling pyrolysis projects, please call for consultation, and Henan DOING Company will serve you wholeheartedly! From small or middle scale batch waste tire pyrolysis plants to big scale fully continuous pyrolysis plant, we all can customize them for you at favorable prices!

contact us

CONTACT US