WhatsApp

WhatsApp

In late May 2025, a 15-ton-per-day (TPD) semi-continuous waste tire pyrolysis plant, customized by Henan DOING Group for a Singaporean client, was successfully installed and commissioned at the project site in Indonesia.

The entire tire to fuel oil recycling pyrolysis system was assembled, tested, and debugged following standardized procedures to ensure reliable performance and long-term stability, earning high praise from the client.

Semi-continuous tire pyrolysis plant in Indonesia

Semi-continuous tire pyrolysis plant in Indonesia

Indonesia Tire to Fuel Pyrolysis Project Objectives

The client, a Singaporean entrepreneur with mining operations in Indonesia, sought to convert locally sourced waste tires into fuel. While familiar with conventional batch-type pyrolysis plants, the client recognized their limitations—particularly in labor-intensive slag discharge (requiring manual removal of steel wires through the reactor door, which generates dust). To address these environmental and efficiency concerns, the client approached DOING Group for a cleaner, more sustainable solution.

DOING's Semi-Continuous Pyrolysis Solution

DOING Group proposed a semi-continuous pyrolysis plant, which improves upon traditional batch tire pyrolysis systems in two key areas:

1. Feeding Process: Pre-shredded tires are automatically conveyed into the tire pyrolysis reactor via an enclosed screw feeder, eliminating manual loading.

Waste tire to ubber powder processing line

Waste tire to ubber powder processing line

2. Slag Discharge: The system enables hot slag extraction without cooling the reactor. A screw discharger transfers carbon black residue to a cooling tank, freeing up the pyrolysis chamber for the next cycle.

This design significantly boosts productivity while maintaining a dust-free workshop environment, aligning with the client’s emphasis on operational safety and environmental compliance.

Waste tire pyrolysis carbon black discharge system

Waste tire pyrolysis carbon black discharge system

Why Choose DOING Group?

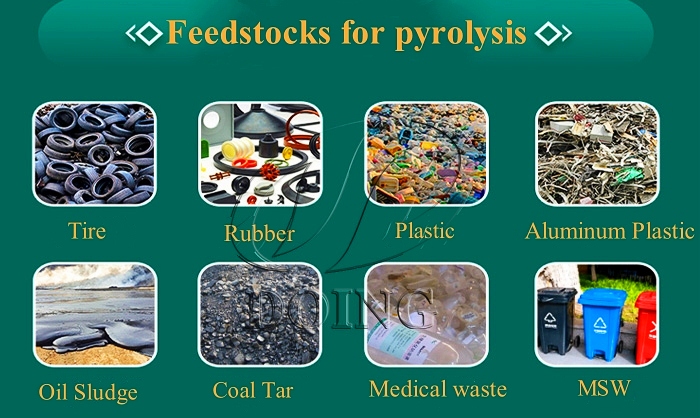

With years of expertise in solid waste pyrolysis, DOING Group offers four product lines: skid-mounted, batch, semi-continuous, and fully continuous pyrolysis plants. Our pyrolysis plants process diverse materials, including: Waste Rubber Tires & Plastics, Oil sludge & drill cuttings, Aluminum-plastic composites, Wind turbine blades & epoxy resin, MSW, etc.

Waste pyrolysis plant recycling feedstocks

Waste pyrolysis plant recycling feedstocks

Backed by stable performance, technical support, and after-sales service, DOING’s solutions serve clients across 90+ countries and won great recognition. For inquiries about waste pyrolysis plant solutions, contact us today.

contact us

CONTACT US