WhatsApp

WhatsApp

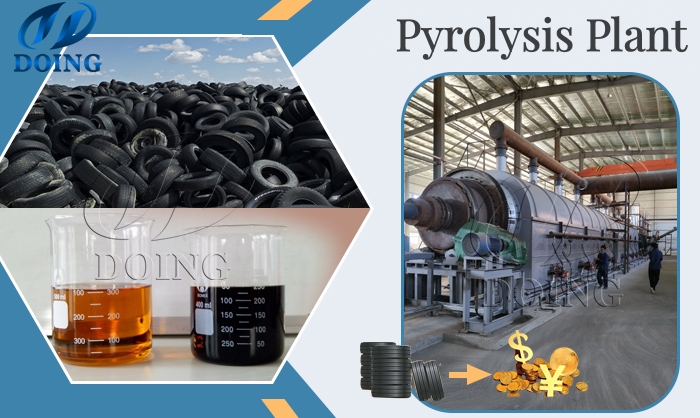

It's reported that the Netherlands is making strides in sustainable tire recycling with the construction of the world's largest tire pyrolysis plant, set to process 20 million end-of-life tires annually. Unlike traditional recycling methods, this facility will convert waste tires into high-value outputs: pyrolysis oil for marine fuel amd petrochemical production, and recovered carbon black (rCB) for rubber and plastics manufacturing.

Waste tire to renewable fuel and carbon black recycling pyrolysis plant

Waste tire to renewable fuel and carbon black recycling pyrolysis plant

From Waste Tires to Renewable Resources

Pyrolysis technology is gaining global recognition for its ability to transform discarded tires into commercially viable products:

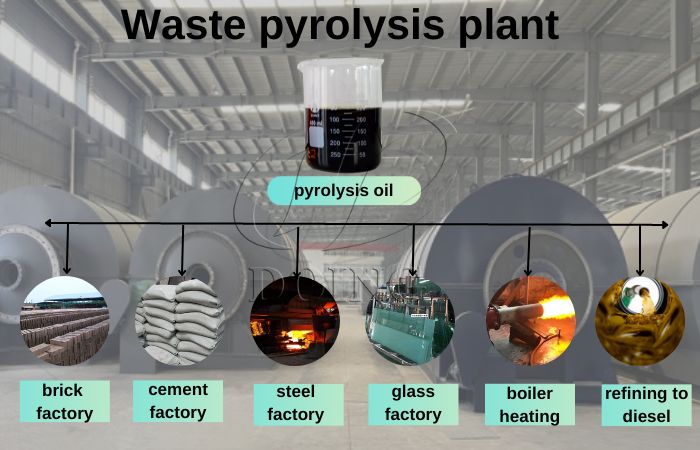

·Pyrolysis Oil: A cleaner alternative to conventional marine fuels, helping the shipping industry, cement/brick/boiler/china/glass heating industries and heavy oil power plant, reduce its carbon footprint. And after refinery by pyrolysis oil distillation plant, the renewable pyrolysis oil can be turned into diesel fuel, which can be used in diesel generators, trucks, marine ships/boats, heavy machinery, etc.

Waste tire renewable pyrolysis oil

Waste tire renewable pyrolysis oil

·Recovered Carbon Black (rCB): Replaces virgin carbon black in tire manufacturing and plastic products, cutting CO₂ emissions by up to compared to traditional production.

Why Pyrolysis Machines Are the Future of Tire Recycling?

Modern tire pyrolysis machines offer an efficient, closed-loop solution for tire waste, ensuring:

✔ Minimal environmental impact – Low emissions and energy-efficient processing.

✔ High economic value – Converts waste into profitable commodities.

✔ Scalability – Suitable for both large industrial plants and smaller recycling operations.

Waste tire recycling pyrolysis benefits

Waste tire recycling pyrolysis benefits

As industries seek sustainable alternatives to fossil fuels and raw materials, pyrolysis-based tire recycling presents a win-win solution—reducing landfill waste while supplying renewable resources.

DOING's tire pyrolysis machine has a single unit capacity ranging from 500kg to 50 tons per day. Models include easy-to-install skid-mounted pyrolysis unit, cost-effective batch pyrolysis reactor, efficient semi-continuous pyrolysis machine, and intelligent fully continuous pyrolysis plant. Our diverse range of models and specifications can meet the operational needs of tire recycling pyrolysis projects, from small-scale to large-scale industrial-scale projects.

Four types of tire pyrolysis machines for sale

Four types of tire pyrolysis machines for sale

Interested in tire pyrolysis oil and rCB production? Contact us to explore how our waste tire to fuel oil production pyrolysis technology can support your sustainability goals.

contact us

CONTACT US