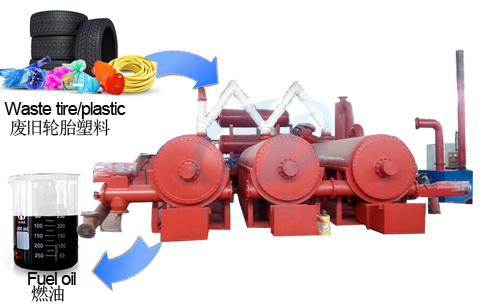

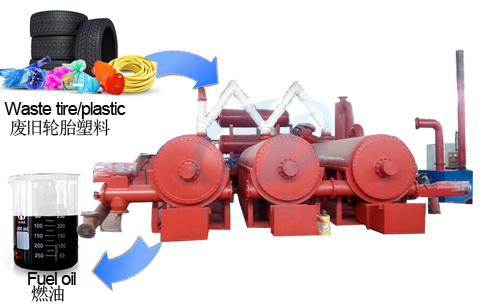

Waste tire/plastic

Plastics are user friendly but not eco-friendly as they are non-biodegradable. Generally it is disposed by way of land filling or incineration of materials which are hazardous. The better binding property of plastics in its molten state has helped in finding out a method of safe disposal of waste plastics, by using them in road laying.

Only in the EU, USA and Japan around 6 million tones per year of scrap tires are produced. The huge quantity of waste tires presently produced in the world will certainly increase in the future as the associated automotive industries grow. The dispos al of scrap tires becomes a serious environmental problem. The accumulation of discarded waste tires leads to environmental pollution. A large fraction of the scrap tires is simply dumped in sites where they represent hazards such as diseases and accidental fires. Rubbers are not biologically degr adable, and this fact creates problems with their disposal. The impact of waste rubber on the environment can be minimized by recycling with material or energy recovery. However, during processing and moulding rubber materials are crosslinked, and therefore they cannot be simply again softened and remoulded by heating. For many years landfill, was the main, practical mean s for dealing with the problem of waste tires. However, landfilling of tires is declining as a disposal option, since tires do not degrade easily in landfills, they are bulky, taking up valuable landf ill space and preventing waste compaction.

A very popular investment that people are making, one that is going to cater to those that are environmentally oriented, is to invest in a continuous pyrolysis plant for waste. This is a factory of sorts that is able to take plastic/tire that has been discarded into a landfill, or even rubber tires, and create marketable products as the end result. All over the world, millions of plastic/tire are being discarded, ending up in landfills, and huge mounds of tires that can sometimes be seen from space are getting even larger with each passing decade. By taking advantage of this thermochemical process called waste pyrolysis, not only can it diminish the amount of waste that is going into landfills, but it will also help shrink the enormous volume of used vehicle tires that are piling up continuously.

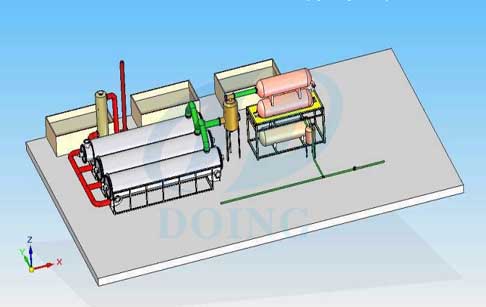

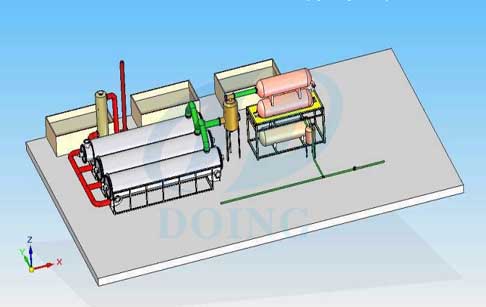

Continuous pyrolysis of plastic and waste tires 3D picture

Here are a few reasons why a continuous waste pyrolysis plant from Doing manufacturer has become so popular as an investment for those that have money that are environmentally oriented.

HennanDoing company produced the continuous pyrolysis of plastic and waste tires ,the pyrolysis plant can convert waste plastic into fuel oil ,carbon black .the fuel oil can apllicatin glass factory,cement factory ,brick factory,etc.

Technical data of continuous pyrolysis of plastic and waste tires

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tire/plastic/rubber |

|

12 |

Output |

Fuel oil, carbon black |

Final product of continuous pyrolysis of plastic and waste tires

Fuel oil application

The main application of fuel oil products by Doing continous pyrolysis of plastic and waste tires is used for industrial and connercial .Such as glass factore ,brick factory,cement factory ,etc

WhatsApp

WhatsApp