What is pyrolysis?

Pyrolysis

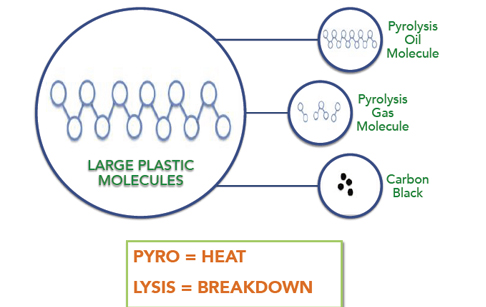

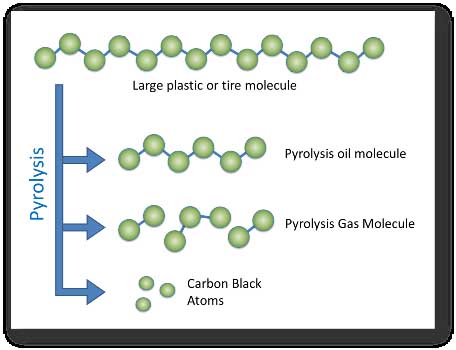

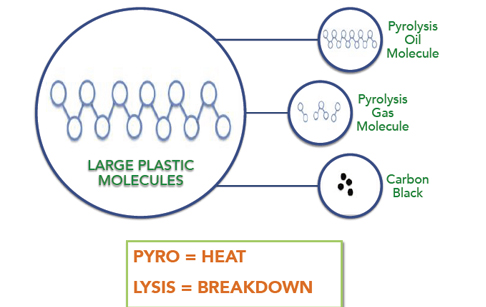

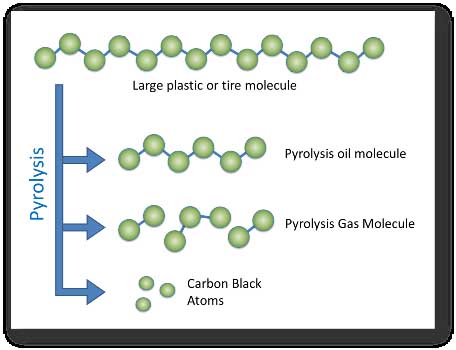

Pyrolysis is a process of chemically decomposing organic materials at elevated temperatures in the absence of oxygen. The process typically occurs at temperatures above 430°C (800°F) and under pressure. It simultaneously involves the change of physical phase and chemical composition, and is an irreversible process. The word pyrolysis is coined from the Greek words "pyro" which means fire and "lysis" which means separating.

Pyrolysis is commonly used to convert organic materials into a solid residue containing ash and carbon, small quantities of liquid and gases. Extreme pyrolysis, on the other hand yields carbon as the residue and the process is called carbonization. Unlike other high-temperature processes like hydrolysis and combustion, pyrolysis does not involve reaction with water, oxygen or other reagents. However, as it is practically not possible to achieve an oxygen- free environment, a small amount of oxidation always occurs in any pyrolysis system.

Types of Pyrolysis

Pyrolysis

There are three types of pyrolytic reactions differentiated by the processing time and temperature of the biomass.

Slow Pyrolysis

Slow pyrolysis is characterized by lengthy solids and gas residence times, low temperatures and slow biomass heating rates. In this mode, the heating temperatures ranges from 0.1 to 2°C (32.18 to 35.6°F) per second and the prevailing temperatures are nearly 500°C (932°F). The residence time of gas may be over five seconds and that of biomass may range from minutes to days. During slow pyrolysis, tar and char are released as main products as the biomass is slowly devolatilized. Repolymerization/recombination reactions occur after the primary reactions take place.

Flash Pyrolysis

Flash pyrolysis occurs at rapid heating rates and moderate temperatures between 400 and 600°C (752 and 1112°F). However, vapor residence time of this process is less than 2s. Flash pyrolysis produces fewer amounts of gas and tar when compared to slow pyrolysis.

Fast Pyrolysis

This process is primarily used to produce bio-oil and gas. During the process, biomass is rapidly heated to temperatures of 650 to 1000°C (1202 to 1832°F) depending on the desired amount of bio- oil or gas products. Char is accumulated in large quantities and has to be removed frequently.

Microwave Pyrolysis Fast pyrolysis has been shown to benefit from the use of microwave heating. Biomass typically absorbs microwave radiation very well, making heating of the material highly efficient - just like microwave heating of food, it can reduce the time taken to initiate the pyrolysis reactions, and also greatly reduces the energy required for the process. Because microwave heating can initiate pyrolysis at much lower overall temperatures (sometimes as low as 200-300°C), it has been found that the bio-oil produced contains higher concentrations of more thermally labile, higher value chemicals, suggesting that microwave bio-oil could be used as a replacement to crude oil as a feedstock for some chemical processes.

Advantages of Pyrolysis

The key benefits of pyrolysis include the following:

1.It is a simple, inexpensive technology for processing a wide variety of feedstocks.

2.It reduces wastes going to landfill and greenhouse gas emissions.

3.It reduces the risk of water pollution.

4. It has the potential to reduce the country's dependence on imported energy resources by generating energy from domestic resources.

5.Waste management with the help of modern pyrolysis technology is inexpensive than disposal to landfills.

6.Construction of a pyrolysis power plant is a relatively rapid process.

7.It creates several new jobs for low-income people based on the quantities of waste generated in the region, which in turn provides public health benefits through waste clean up.

Applications

Some of the major applications of pyrolysis include the following:

It is widely used in chemical industry to produce methanol, activated carbon, charcoal and other substances from wood.

Synthetic gas produced from the conversion of waste using pyrolysis can be used in gas or steam turbines for producing electricity.

A mixture of stone, soil, ceramics and glass obtained from pyrolytic waste can be used as a building material - construction slag or for filling landfill cover liners.

It plays a major role in carbon-14 dating and mass spectrometry.

It is also used for several cooking procedures like caramelizing, grilling, frying and baking.

Henan Doing produced waste tyre/plastic pyrolysis plant adopt this pyrolysis technology ,the pyrolysis plant can conversion waste tyre/plastic to fuel oil ,carbon black and steel .