WhatsApp

WhatsApp

In December 2025, Henan Doing Group completed the production and loading of a 15TPD batch-type plastic pyrolysis plant for a client in India. After rigorous quality inspections and careful packaging, all components were loaded onto trucks and dispatched to the port for their journey to the India. Here is shipping video:

As a practical and flexible waste treatment solution, batch plastic pyrolysis plant is well-suited for small and medium-sized recycling projects in India. It adopts a “start-stop” cycle operation mode, allowing easy switching between different types of plastic waste without major reconfiguration, which fits the diverse characteristics of India’s plastic waste streams.

The shipped 15TPD batch plastic pyrolysis plant has a complete configuration, covering the entire process of plastic pyrolysis and product collection, with outstanding environmental protection and operational stability. The detailed shipment list and key advantages are as follows:

Delivery of DOING waste plastic pyrolysis plant to India

Delivery of DOING waste plastic pyrolysis plant to India

1. 15TPD plastic pyrolysis reactor: Equipped with both a cold air device and water film dust removal system. The cold air device ensures stable reactor temperature during operation, extending plant service life; the water film dust removal effectively captures dust generated during the process, reducing air pollution and meeting India’s emission standards for particulate matter (PM).

2. Carbon black hoist: Used for automatic lifting and conveying of carbon black, a solid by-product of plastic pyrolysis plant. It simplifies the post-processing process, reduces manual labor intensity, and improves work efficiency.

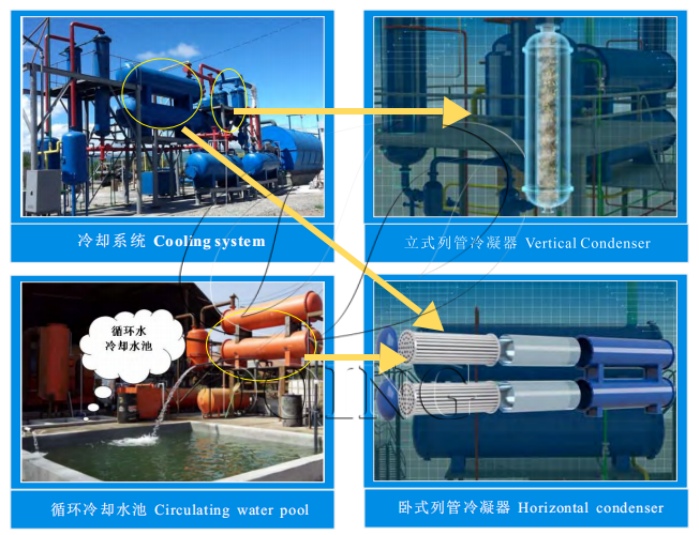

3.Tube condenser: Adopts efficient heat exchange technology to condense pyrolysis gas into liquid pyrolysis oil, improving the recovery rate of pyrolysis oil and ensuring stable product quality. The design is easy to clean and maintain, suitable for long-term operation in India’s working environment.

DOING tube cooling system

DOING tube cooling system

4.Heavy oil burner: Uses heavy oil produced during the pyrolysis process as fuel, realizing energy recycling, reducing fuel costs, and aligning with India’s circular economy development concept.

5.Oil tank: Used for sealed storage of pyrolysis oil, preventing oil leakage and ensuring safe storage and transportation of the product.

6.Chimney: Discharges treated exhaust gases at a reasonable height, further reducing the impact of exhaust gases on the surrounding environment and meeting local environmental protection requirements.

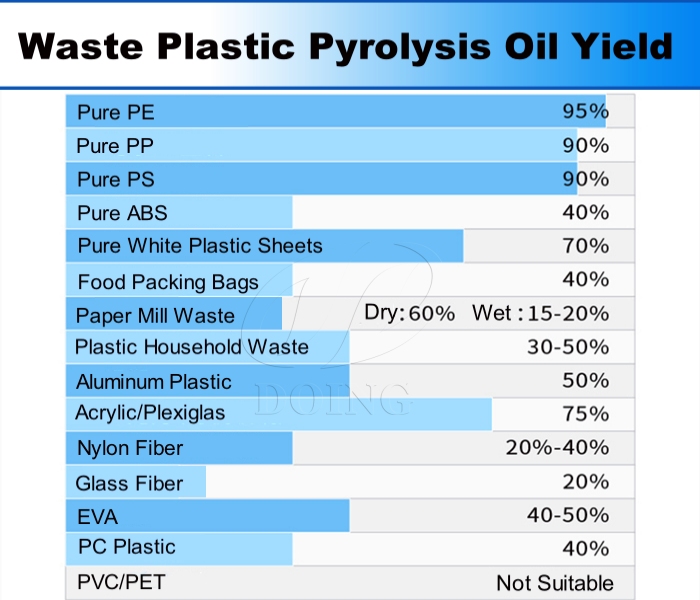

Plastic oil yield of pyrolysis

Plastic oil yield of pyrolysis

As the 15 TPD waste plastic pyrolysis machines arrive in India, Henan DOING engineering team will provide remote or on-site guidance to assist with the assembly, commissioning, and operator training, ensuring the project starts generating ROI as soon as possible. Welcome to follow our YouTube account mentioned above, Henan DOING will provide real-time updates on its operation.

contact us

CONTACT US