WhatsApp

WhatsApp

In May,2025, we have successfully closed a deal with a Zambian customer who ordered a set of our advanced DOING 14-ton new type distillation equipment. This Zambian customer runs a glass manufacturing plant and owns a set of waste tire pyrolysis equipment, converting waste tires into high-calorific-value fuel oil. By distilling this tire derived fuel (TDF) through DOING 14-ton new type distillation equipment, this Zambian customer aims to supply cleaner, more sustainable fuel for their glass furnace while significantly cutting operational costs.

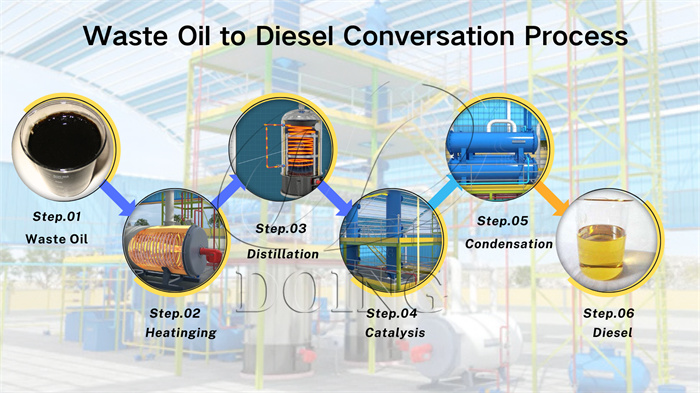

Process of waste oil to diesel distillation machine

Process of waste oil to diesel distillation machine

Tire pyrolysis oil boasts a calorific value of 9,500–10,500 kcal/kg, comparable to industrial diesel, but at a low cost. However, raw tire oil contains impurities, In order to obtain cleaner oil, ensure its combustion in the glass production process is more environmentally friendly and broaden the use of tire pyrolysis oil. This Zambian customer ordered a set of DOING 14-ton new type distillation equipment.

Refined tyre pyrolysis oil application

Refined tyre pyrolysis oil application

The reason why this Zambian customer chose DOING is multi - fold. First of all, after visiting DOING factory, the customer was deeply impressed by our well - developed technology. Our R & D team has been constantly working on improving and innovating the distillation technology to ensure the high - quality output of refined oil. Secondly, the scale and strength of DOING factory also left a strong impression on this Zambian customer. With advanced production lines and a large - scale manufacturing base, we can guarantee the timely delivery of equipment and reliable after - sales service. In addition, there are already numerous customers who have purchased DOING distillation equipment and put it into successful operation, such as South Africa, India, Ghana, Mexico, Colombia, Egypt, United States, New Zealand, France, United Kingdom, Philippines. These practical cases are the best demonstration of the reliability and effectiveness of our products.

Customer cases of DOING distillation equipment

Customer cases of DOING distillation equipment

For customers in industries such as cement factories, brick factories, glass factories, gypsum factories, ceramic factories, power plants, steel mills, and boiler plants, if you are looking for ways to reduce factory operating costs, please do not hesitate to contact us. We can provide you with a complete solution from pyrolysis to distillation. Our professional team will customize the most suitable plan according to your specific needs, helping you to achieve cost - savings and efficiency improvements.

contact us

CONTACT US