WhatsApp

WhatsApp

Pyrolysis machines have gained popularity in the recycling industry, offering the ability to convert tires, plastics and oil sludge into valuable products such as fuel oil, carbon black, and steel wire (in the case of tires). Additionally, syngas produced during the process can serve as a heating fuel alternative to traditional oil. When establishing a pyrolysis machine project, it is important to consider the employees during the pyrolysis machine operation in addition to purchasing a suitable pyrolysis machine.

Employees needed for pyrolysis machine operation

Employees needed for pyrolysis machine operation

Generally, the operation of a pyrolysis machine involves three primary processes that need employees to work:

1. Feeding: The feeding process typically necessitates the presence of two employees. One employee controls the auto-feeder, while another operates the grabber to feed automated tires and plastic into the pyrolysis reactor. In cases where an auto-feeder is not available, additional employees may be required to manually feed the raw materials.

Auto-feeder of DOING pyrolysis machine

Auto-feeder of DOING pyrolysis machine

2. Heating: During the heating phase, at least one employee is essential to monitor and control the oil burners. Temperature regulation is crucial, with specific temperature ranges needing to be maintained depending on the type of material being processed. For tire recycling, temperatures between 280-320 degrees are optimal, while plastic recycling requires temperature control within the range of 260-280 degrees.

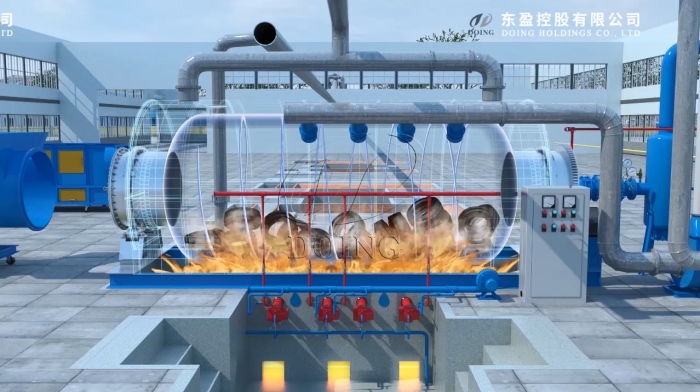

Reactor heating of DOING pyrolysis machine

Reactor heating of DOING pyrolysis machine

3. Discharging carbon black: Normally the process of discharging carbon black typically requires one employee to assist with packaging and the other employee to control lifter.

For tire recycling, an additional worker may be required for the steel wire drawing process. This worker would be responsible for controlling the grabber to facilitate the efficient extraction of steel wire. Therefore, in total, it is estimated that 3-4 employees are needed to effectively operate a pyrolysis machine.

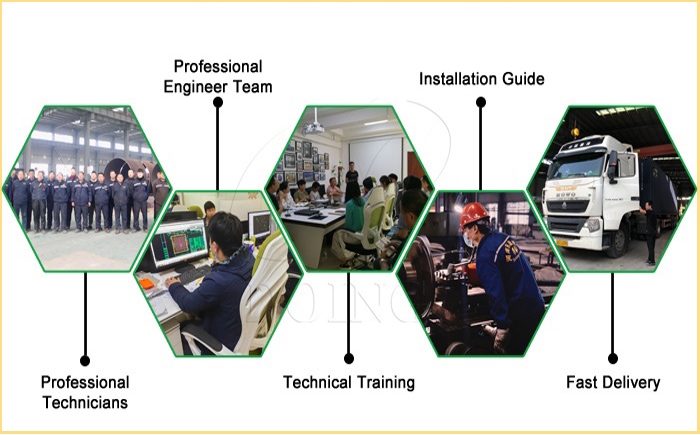

In summary, the number of employees that need pyrolysis machine operation is affected by the automation and design of the equipment. Over the past 14 years, DOING has been committed to updating the technology and design of pyrolysis machine to enhance its work performance and save time and labor cost for our customers. And now our new designed fully continuous pyrolysis machine has become a hot popular choice for many customers, which needs rather fewer employees during the operation. Additionally, DOING also can provide technical guidance and training for the employees to enhance the successful setting of the pyrolysis machine project.

Comprehensive services provided by DOING

Comprehensive services provided by DOING

Should you have any further questions regarding the operation of a pyrolysis machine or its labor requirements, please do not hesitate to contact us for more information.

contact us

CONTACT US