WhatsApp

WhatsApp

Pyrolysis machine is an attractive treatment solution and is widely used in the recycling and treatment of solid waste such as waste tires, waste plastics, waste aluminum plastics, waste oil sludge, coal tar residue, etc. When setting up a waste pyrolysis plant project, an environmental impact assessment (EIA) is a very critical part.

The following are some common EIA requirements for setting up a pyrolysis plant:

Environmental impact assessment of setting up pyrolysis plants

Environmental impact assessment of setting up pyrolysis plants

1. Environmental impact prediction: Predict the types, quantities and characteristics of waste gases, wastewater, and solid waste generated during the pyrolysis process. Assess the possible direct and indirect impacts on air, water, soil, ecosystems and human health.

2. Emission standards and control: Ensure that the waste gases (such as carbon dioxide, carbon monoxide, volatile organic compounds, heavy metals, etc. generated during the waste pyrolysis plant operation process meet national or regional emission standards.

3. Wastewater treatment: Pre-treat and post-treat the wastewater generated during the pyrolysis process to ensure that it meets the emission standards. It may be necessary to set up a sewage treatment plant or connect to the municipal sewage treatment system.

Environmental impact assessment of pyrolysis plants

Environmental impact assessment of pyrolysis plants

4. Solid waste disposal: Determine the disposal method of solid residues (such as carbon black) produced by pyrolysis, whether they can be reused or need to be safely landfilled. Develop a plan for the classification, collection, storage and transportation of solid waste.

5. Noise and vibration: Assess the noise and vibration levels during the operation of the pyrolysis plant, and take sound insulation and vibration reduction measures.

6. Risk assessment: Identify potential risks such as fire, explosion and leakage during the pyrolysis process, and develop emergency plans.

7. Legal and policy compliance: Ensure that the project complies with all applicable environmental laws, regulations and policy requirements.

The above highlights the reference items for environmental assessment of establishing a pyrolysis plant. For some countries with strict waste treatment and recycling requirements, a detailed environmental impact assessment report must be completed and approved by relevant government departments before setting up a pyrolysis plant project.

Environmental pyrolysis plant projects set up by Henan DOING

Environmental pyrolysis plant projects set up by Henan DOING

DOING pyrolysis machine adopts an environmentally friendly design and meets the relevant requirements of many countries. At present, our pyrolysis machines have been sold to more than 100 countries and regions, even including the requirements of Europe, America and even some tourist countries such as Fiji, without any problems.

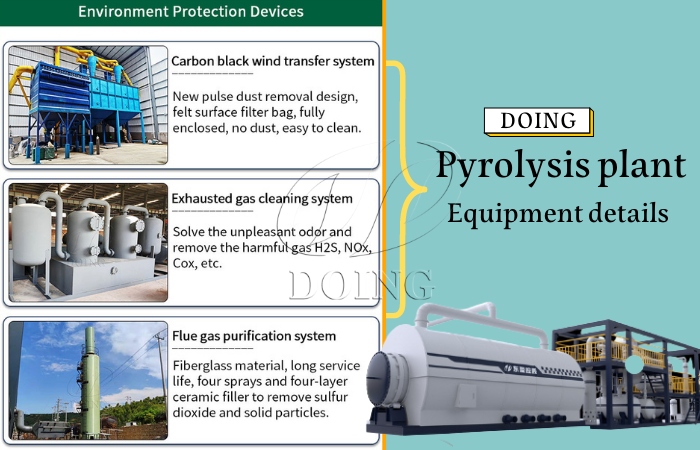

In view of the important indicators of environmental assessment standards, DOING Brand pyrolysis machine has undergone special environmental protection design:

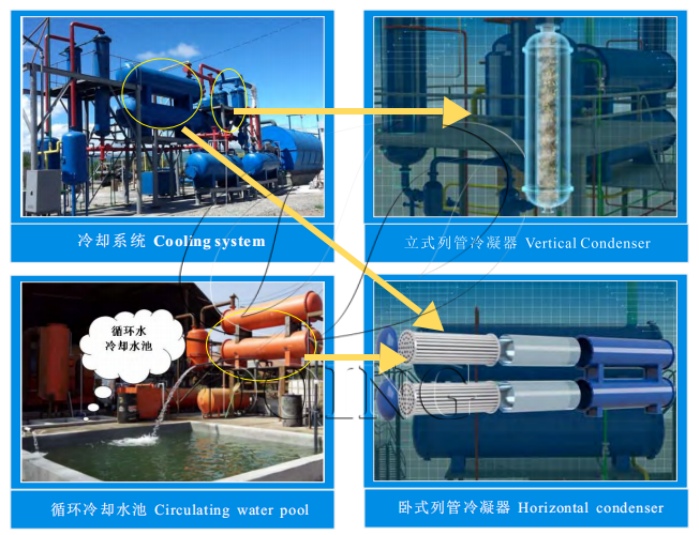

1. Water consumption: The water used in the entire pyrolysis system is divided into two parts. One part is used as circulating cooling water to cool the hot oil gas. The other part is used as flushing water to remove sulfur and dust during flue gas purification, which is also recycled and does not need to be discharged, but can be added regularly with evaporation.

Circulating water cooling system of DOING pyrolysis plant

Circulating water cooling system of DOING pyrolysis plant

2. Exhaust emissions: DOING environmental pyrolysis machine is designed with an effective and high-standard exhaust gas purification system, such as dust collector, desulfurization device, denitrification device and activated carbon adsorption, etc., to ensure that the exhaust gas meets the emission standards.

Exhaust gas purification system of pyrolysis plant

Exhaust gas purification system of pyrolysis plant

If you want to set up an environmentally friendly pyrolysis plant, you must choose a manufacturer with rich project experience, mature environmental protection technology, customized services, and pre-sales and after-sales services. Henan Doing Company is a good choice for you, please don’t hesitate to inquire us.

contact us

CONTACT US