WhatsApp

WhatsApp

Can sludge be used as fuel? The answer is yes—with professional pyrolysis technology. Sludge is often considered a toxic waste and difficult to dispose of due to its high moisture, heavy metal, and organic contaminant content. However, its inherent organic matter (30–60% by dry weight) contains recoverable energy, making it a viable fuel source when processed correctly. DOING sludge pyrolysis equipment transforms this "environmental burden" into usable fuel, solving disposal challenges while creating economic value.

1.Why raw sludge can’t be used as fuel directly

Raw sludge lacks fuel usability and poses severe risks if burned without treatment:

①High moisture content: Sewage sludge typically has 70–90% moisture, and oil sludge 50–80%. Burning wet sludge requires massive energy to evaporate water, leading to low combustion efficiency (often<30%) and high fuel consumption for auxiliary heating.

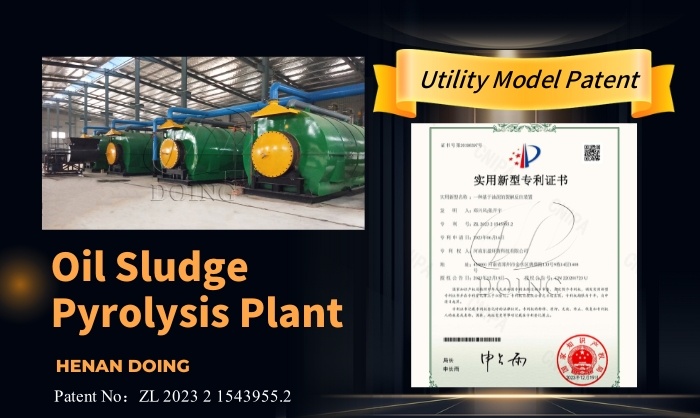

DOING sludge pyrolysis equipment

DOING sludge pyrolysis equipment

②Toxic emissions: Direct incineration of raw sludge releases heavy metals (lead, mercury), dioxins, and sulfur oxides which endanger public health.

③Poor handling: Raw sludge is viscous and odorous, making transportation and storage difficult. It also risks leaching pollutants into soil and groundwater if landfilled, rather than being repurposed as fuel.

2.How does oil sludge pyrolysis work?

Pyrolysis is a chemical process that breaks down materials under high-temperature, oxygen-free conditions. For oil sludge, this means that long-chain hydrocarbon molecules are broken down into smaller molecules, producing oil and gas vapors. These vapors are then cooled and condensed into pyrolysis oil, which can be used as fuel.

This method provides a sustainable solution for oil sludge management while also recovering valuable energy. As a leading sludge pyrolysis equipment manufacturer, DOING offers professional solutions for oil sludge fuel conversion. Our sludge pyrolysis equipment is designed to be efficient, safe, and environmentally friendly.

DOING sludge pyrolysis equipment advantages

DOING sludge pyrolysis equipment advantages

Key advantages of DOING sludge pyrolysis equipment:

①High oil yield: DOING sludge pyrolysis equipment features an advanced four-stage condensing unit. This design maximizes the condensing surface area, ensuring thorough cooling of the oil and gas vapors, significantly increasing oil yield.

②High-quality oil: The oil-water separator is a crucial component of the condensation system, preventing gas backflow and filtering out water vapor and impurities, thereby improving the purity of the final pyrolysis oil.

③Safe. DOING sludge pyrolysis equipment is equipped with a negative pressure device to extract residual oil and gas from the reactor after treatment. This reduces the internal pressure of the reactor, ensuring safe operation under normal atmospheric conditions, protecting workers and equipment.

④Environmental: DOING sludge pyrolysis equipment is designed with a comprehensive environmental protection system. Harmful gases generated during operation are treated in a desulfurization and purification tower, ensuring emissions meet international environmental standards. The entire process is clean and pollution-free.

⑤Smooth operation:In order to solve the inevitable coking problem caused by the complex composition of oil sludge, DOING has configured a decoking device to solve it.

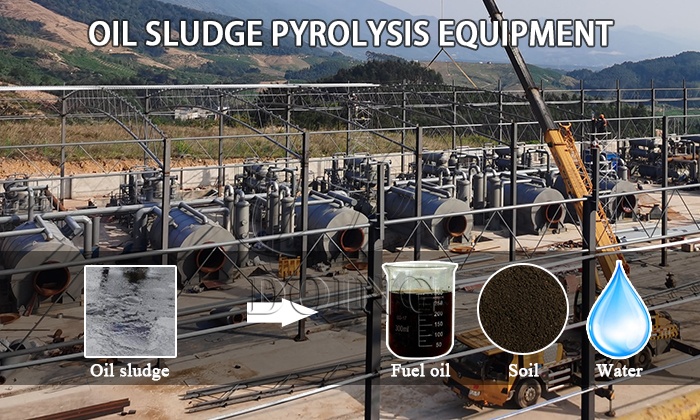

3.Applications of sludge pyrolysis product

DOING sludge pyrolysis equipment

DOING sludge pyrolysis equipment

①15-70% pyrolysis oil: It can be used in a variety of industrial environments, including heavy oil generators, boiler heating systems, cement plants, and steel mills, etc..

②20-25% residue: It is used for fuel additive or asphalt filler or safely landfilled.

③ 5-10% syngas: It is used for heat reactor.

4.Who benefits from DOING sludge pyrolysis equipment?

①Oil refineries/petrochemical plants: Recycle oil sludge into pyrolysis oil, replacing purchased heavy fuel oil and reducing environmental fines for improper sludge disposal.

②Industrial facilities: Factories generating chemical or printing sludge can turn waste into fuel for production lines, improving sustainability and lowering operational expenses.

③Waste management companies: Offer sludge-to-fuel services to clients, creating a new revenue stream.

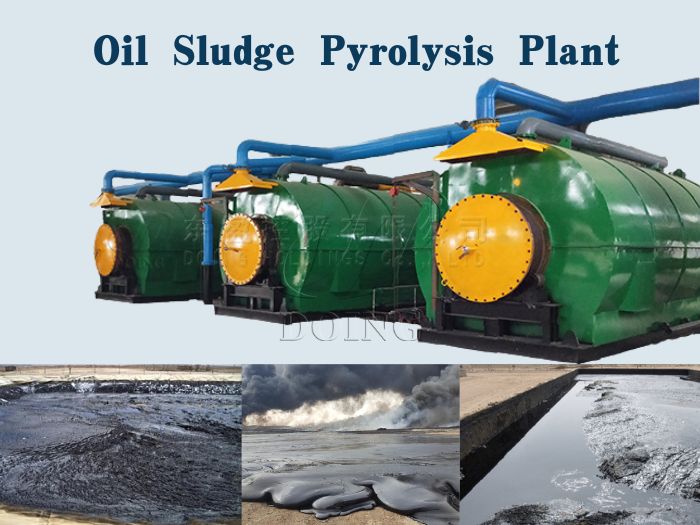

DOING sludge pyrolysis equipment

DOING sludge pyrolysis equipment

Many people are unaware that oil sludge, such as drilling mud, tank-bottom sludge, oil-based cuttings, contaminated soil, drill cuttings, water-based mud, tank-bottom oil sludge, oil/synthetic mud, coastal sludge, etc., can be reused as fuel. DOING sludge pyrolysis equipment unlocks this potential, converting toxic sludge into usable fuel while meeting environmental standards. For those looking to solve sludge disposal problems and create value from waste, DOING solutions are a reliable choice. Contact DOING for a complete solution.

contact us

CONTACT US