WhatsApp

WhatsApp

Waste tire pyrolysis plant is a kind of waste recycling plant which can convert the waste plastic into fuel oil, carbon black and steel wires. Now, it has been very popular all over the world. But after all, the waste tire pyrolysis plant is a big set of machine, in order to keep safety, we need to notice the following points during running the waste tire pyrolysis plant.

1.We do not recommend customer start the operation only by referring to the operation manual without the guidance of our professional technicians. The operators must be trained two or three times by our professional technicians.

The 3D pictuture of waste tire pyrolysis plant

The 3D pictuture of waste tire pyrolysis plant

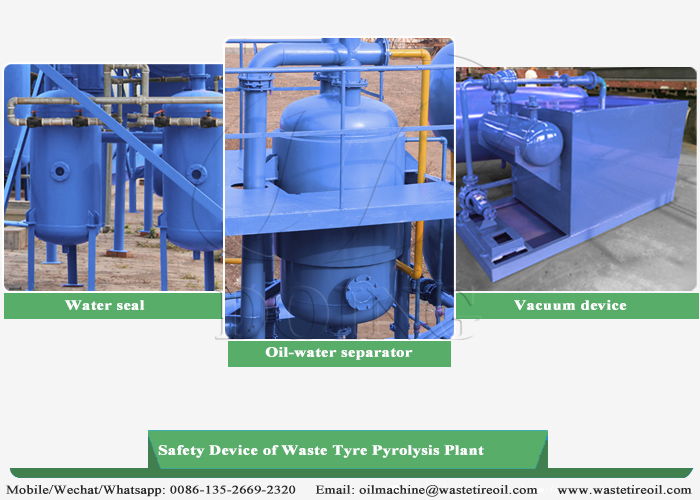

2.Before running the waste tire pyrolysis plant, you need to make sure all parts in good condition. Such as motors, pumps, power systems, etc. And checking the water level inside the oil-water separator and water seal devices.

Safety device of waste tire pyrolysis plant

Safety device of waste tire pyrolysis plant

3.During the running process of waste tire pyrolysis plant, you should check the temperature gauge, and record the temperature regularly. you need to control the heating burner based on different temperature. And the pressure gauge should be checked during operation to see if shows the normal operation pressure (there is no pressure under normal operation).

The pressure gauge of waste tire pyrolysis plant

The pressure gauge of waste tire pyrolysis plant

4.At the end of running the waste tire pyrolysis plant, you need to make sure all waste tiers has been pyrolyzed fully. After cooling the reaction vessel, it’s time to discharge the carbon black. Our waste tire pyrolysis plant uses an advanced carbon black wind conveying system that automatically discharges carbon black into storage tanks in a closed environment. By this system, to ensure the cleanliness of the scrap tire pyrolysis plant site.

The carbon black discharge device of waste tire pyrolysis plant

The carbon black discharge device of waste tire pyrolysis plant

5.Then opening the negative pressure device and reactor cooling system to quickly cool the pyrolysis reactor down which can help you start the next operation as soon as possible.

6.Except paying attention to the operation process, the general maintenance of waste tire pyrolysis plant also plays an import role of the working life of the equipment, such as adding lube oil regularly, checking pumps, changing V belts etc.

Now, this waste tire pyrolysis plant has been installed over 80 countries. If you also want to start the waste tire to fuel oil business, please feel free to contact us! And when you start running the machine, please pay attention to these points.

contact us

CONTACT US