WhatsApp

WhatsApp

Welcome to our video about the working principle of pyrolysis technology! If you’ve ever wondered how common wastes like rubber tires and plastics are turned into valuable resources, this video will give you a clear and easy-to-understand explanation:

As the video opens, we directly focus on the core question: What is the working principle of pyrolysis technology? Simply put, as explained in the video, pyrolysis is a thermal decomposition process that breaks down materials at high temperatures, with a crucial premise—no oxygen is allowed in the process. This oxygen-free environment ensures that wastes are transformed into new usable products instead of being burned to ash.

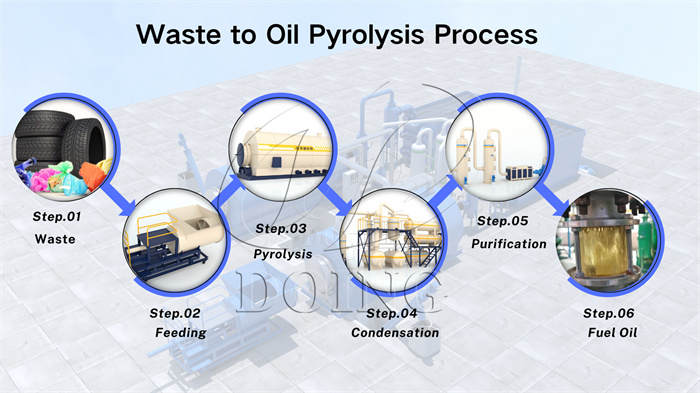

Waste to fuel pyrolysis process

Waste to fuel pyrolysis process

The video then breaks down the working process step by step, making the professional principle easy to grasp: First, organic waste materials (such as rubber tires, plastics, etc.) are put into the reactor of the pyrolysis machine. Next, the pyrolysis reactor is heated to a temperature between 300℃ and 500℃. When the raw materials reach this temperature range, wonderful chemical reactions occur—this is the core link of the pyrolysis process. The long carbon and hydrogen molecular chains in the organic wastes will break down into smaller molecular fragments, and these fragments will then reorganize into new valuable products, including pyrolysis oil, carbon black and syn-gas.

Waste to fuel application

Waste to fuel application

The core of pyrolysis plant working principle lies in controlling conditions such as temperature, pressure and reaction time to realize the cracking of organic raw materials in an oxygen-deficient environment, thereby achieving resource regeneration and reuse. Please feel free to contact us for more information about pyrolysis.

contact us

CONTACT US