WhatsApp

WhatsApp

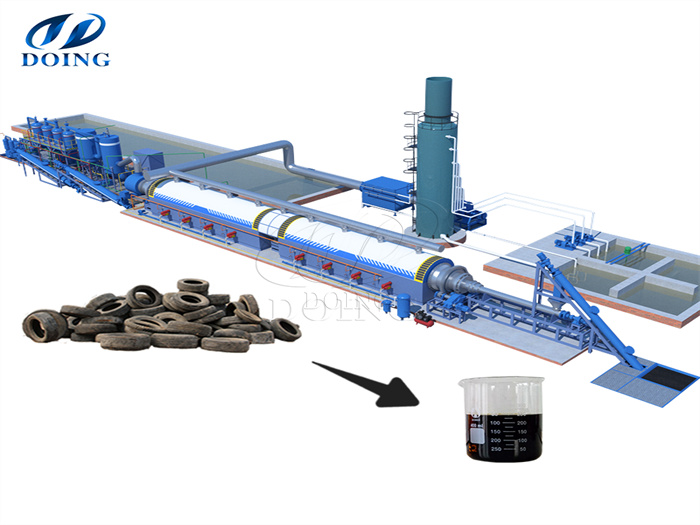

3D picture of fully automatic continuous tyre pyrolysis plant

3D picture of fully automatic continuous tyre pyrolysis plant

Fully automatic continuous tyre pyrolysis plant refers to an advanced technology in which waste tyres are continuously fed into a reactor and subjected to high temperatures in the absence of oxygen, causing them to break down into smaller molecules. This results in the production of valuable products such as oil, carbon black, steel wire, and gas. The term "fully automatic" implies that the system operates with minimal human intervention, using automated controls for feeding, temperature regulation, pyrolysis oil production and final carbon black discharging.

DOING fully automatic continuous pyrolysis technology is designed for efficiency, large-scale operations, and reduced environmental impact compared to traditional tire disposal methods.

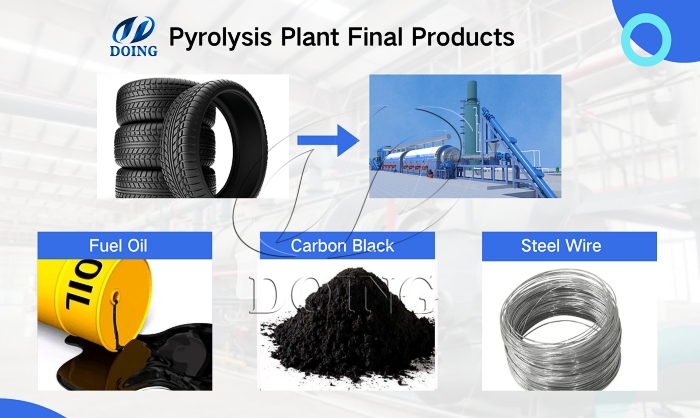

Fully automatic continuous pyrolysis plant final products

Fully automatic continuous pyrolysis plant final products

1. DOING fully automatic continuous pyrolysis solution

For us, we mainly specialized in manufacturing and supplying waste tire/plastic/rubber pyrolysis plants, mostly for processing rubber products to get fuel oil. On one hand, with the modernization of society, the rubber industry develops at a rapid speed, rubber manufactures are widely used in many fields of life. On the other hand, the pollution of scrap rubber or plastics is increasing because of its difficulty in disposing safely, which is also called “Black Contamination”, has become a big threat to the environment and is getting increasingly serious. Pyrolysis Technology offers a sustainable and efficient solution to manage waste rubber tires and turn waste tires into wealth.

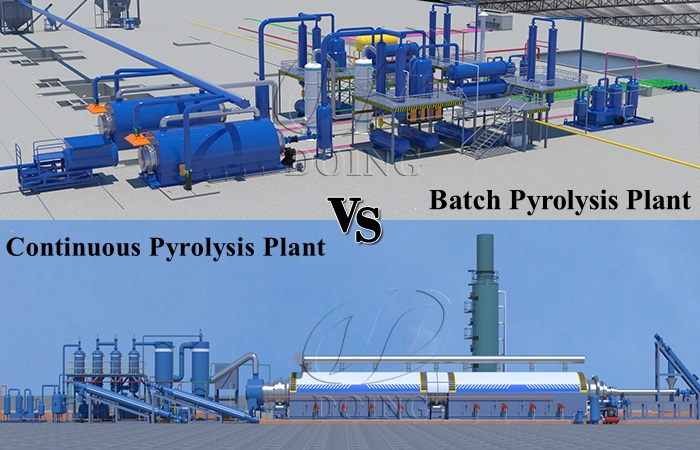

In the early years, the most commonly used pyrolysis plant is mainly the batch operation process, which has low investment but complicated operation process and high labour cost. With the technology improving and customers' requests, we DOING Company developed a new technology continuous pyrolysis plant. This continuous pyrolysis plant has fully automatic process, which can be controlled by PLC system or computer, thus to save the labour cost. And with the automatic and continuous feeding and discharge system, it can make the pyrolysis system keep running 24/7 without stop, thus to save the valuable time and energy which are consumed in the batch manual operation system.

Batch continuous tyre pyrolysis plants

Batch continuous tyre pyrolysis plants

2. DOING sale fully automatic continuous pyrolysis plant improvements

DOING Fully Automatic Continuous Tyre Pyrolysis plant has significantly evolved, focusing on efficiency, eco-friendliness, and commercial viability. It has the following key advancements:

•Enhanced Energy Efficiency: Newer systems feature better insulation and heat recovery mechanisms, reducing energy consumption. From waste rubber feeding to final products collection, the whole continuous pyrolysis process is carried out in a sealed situation.

•Continuous Feed & Product Output: DOING Sale fully automatic continuous tyre pyrolysis plant now support continuous feedstock input and simultaneous product extraction, optimizing operational efficiency.

•Improved Safety Measures: Integrated safety systems ensure controlled processing environments, complying with stringent safety standards. We can also equip fully PLC control system to achieve the intelligent management of the whole fully automatic continuous pyrolysis process.

PLC control system of Batch continuous tyre pyrolysis plants

PLC control system of Batch continuous tyre pyrolysis plants

•Heat Energy Recovery: The syn-gas generated is recovered, often reused to power the heating system, minimizing external energy needs.

•Environmental Compliance: Designed to adhere to international environmental standards and local emission regulations. It can even meet the strict EU standards.

These improvements position tire pyrolysis as a sustainable solution for waste tire management and a competitive alternative fuel solution. If you aim at enhancing efficiency, product quality, and environmental sustainability further of waste tire pyrolysis, DOING sale fully automatic tire pyrolysis plant is an ideal option.

Tchnical data of Sale fully automatic continuous tyre pyrolysis plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

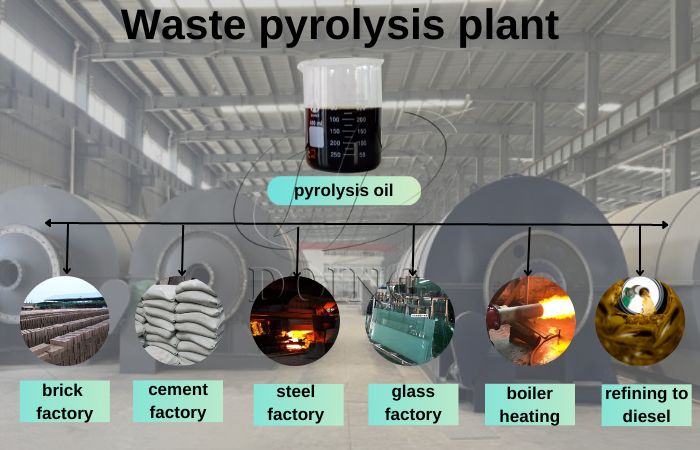

Sale fully automatic continuous tyre pyrolysis plant application Waste pyrolysis oil applications

Waste pyrolysis oil applications

1. Fuel oil (45%-50%): Oil from fully automatic continuous tyre pyrolysis plant can be used as industrial fuel for burning.

2. Carbon black (30%): First, Carbon black from fully automatic continuous tyre pyrolysis plant is crude. You can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. Second, could make further process, make carbon black powder into carbon black briquette, and use it for burning.

3. Steel wire (10-15%): It can be sold to the iron and steel company directly.

4. Waste gas (5%): we have a special design could recycling it into fire furnace for burning.

contact us

CONTACT US