WhatsApp

WhatsApp

There are many pyrolysis plant manufacturers in the market, but different manufacturers have different requirements for equipment, which leads to the phenomenon that the quality of pyrolysis plants varies. When you decide to buy pyrolysis plant, it’s necessary to examine the manufacturer's quality control of pyrolysis plant, the comprehensive strength, as well as the maintenance and after-sales service, so as to choose the best pyrolysis plant manufacturer.

First of all, while fabricating the pyrolysis plant, a professional and reliable manufacturer will strictly control the design of overall processing technology, manufacturing raw materials, welding technology, etc. of the pyrolysis plant. Because under the premise of long-term high temperature heating and pyrolysis, the pyrolysis plant needs to have very strong pressure resistance and sealing ability. The better the quality of the pyrolysis plant and the more stable its operation, it will help customers to obtain higher oil yield and more profit.

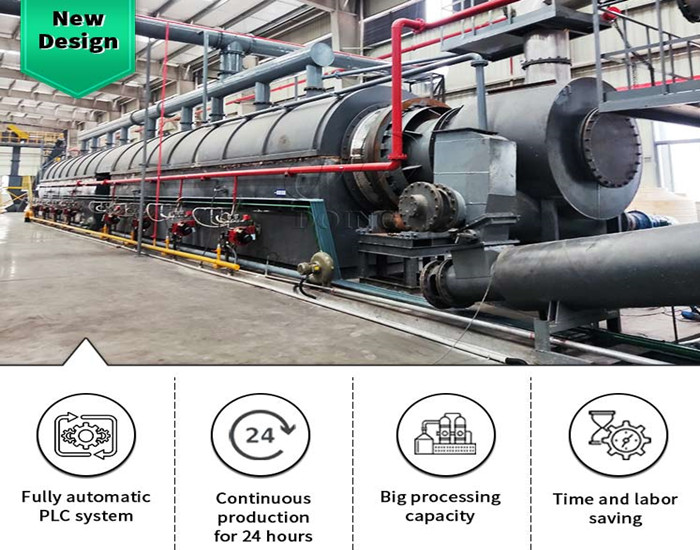

Waste plastic/tyres to fuel oil recycling pyrolysis plant

Waste plastic/tyres to fuel oil recycling pyrolysis plant

Secondly, for a good pyrolysis plant manufacturer with complete comprehensive strength, it is necessary to have independent process department, design department, technical department, purchasing department and production department to coordinate to ensure the reliability, safety and stability of equipment production. And good pyrolysis plant manufacturers should have their own independent manufacturing factory. In this way, customers can conduct on-site inspections to learn about factory capacity, production links and machine production processes.

In addition, the manufacturer with complete comprehensive strength has rich experience in the installation of pyrolysis plants projects, and can provide customers with professional production solutions, pyrolysis plant project pictures and videos for customer reference.

Project cases

Project cases

Last but not least, customers should pay attention to whether the equipment maintenance and after-sales service provided by pyrolysis plant manufacturers are complete. Generally, good pyrolysis plant must be repeatedly tested and debugged before the official purchase to make the performance indicators of the equipment reach a good state, and there are relevant training services to ensure that the customer can get the pyrolysis business started in time after purchasing the pyrolysis plant, in addition to after-sales service solutions, to ensure that follow-up issues are resolved in a timely manner.

The service of DOING company

The service of DOING company

Henan Doing Company has more than 11 years of experience in the manufacture and export of pyrolysis plants, which can help customers to efficiently and environmentally friendly convert waste tires, waste plastics, waste rubber, sludge and other raw materials into oil fuel, combustible gas, etc., and obtain considerable profits. DOING can provide each customer with the best waste treatment solutions, cost-effective pyrolysis plants, the shortest delivery time and the best service. If you are interested in this, please feel free to contact us.

contact us

CONTACT US