WhatsApp

WhatsApp

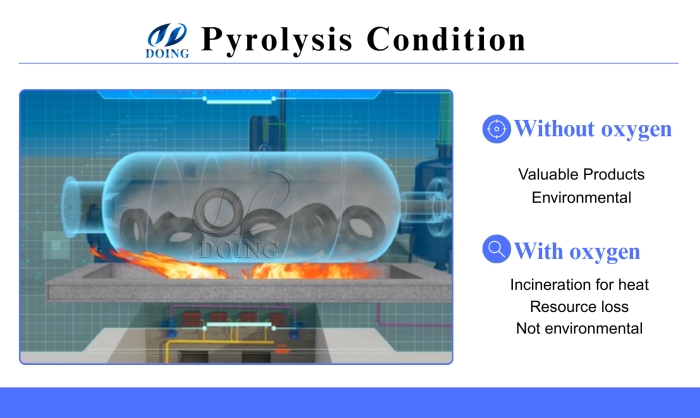

Pyrolysis is widely used in the fields of organic waste treatment, biomass energy production and material recycling. Its core is to decompose organic materials at high temperature to generate gas, liquid (pyrolysis oil) and solid (such as carbon black, biochar) products. However, the execution conditions of pyrolysis, especially the presence or absence of oxygen, will directly affect the reaction path, product composition and environmental performance.

In fact, unlike incinerators (which require oxygen participation), the key to the operation of pyrolysis equipment lies in its oxygen-free or low-oxygen environment, that is, anaerobic pyrolysis. Specifically, the pyrolysis process needs to eliminate or minimize the presence of oxygen through a certain positive or negative pressure device. Here is the video, which displays the detailed principle of pyrolysis technology:

Why does pyrolysis require oxygen-free conditions?

1. Avoid oxidation reaction

When oxygen is present, organic matter will preferentially combine with oxygen to burn and generate CO₂ and H₂O, which cannot be converted and recovered into liquid fuel, gas and other products to the maximum extent. For example, in the pyrolysis of waste tires, the oxygen-free environment can break the rubber polymer chain into hydrocarbons (pyrolysis oil), carbon black and steel wire. If there is oxygen, it will burn to generate waste gas, reducing the resource recovery rate.

Pyrolysis conditions with and without oxygen

Pyrolysis conditions with and without oxygen

2. Control the direction of the reaction

Anaerobic pyrolysis is an endothermic reaction (external heating is required), while aerobic incineration is an exothermic reaction. The anaerobic pyrolysis conditions ensure that energy is used for molecular decomposition rather than combustion, increasing the calorific value and utilization value of the product (such as pyrolysis oil can be used as fuel or further refined into non-standard diesel or other types of oil products).

3. Environmental protection needs

The oxygen-free pyrolysis environment can reduce the generation of pollutants. For example, combustion may produce harmful gases such as dioxins and nitrogen oxides. And through the exhuast gas treatment system (such as desulfurization and dust removal), it is easier to achieve standard emissions and meet global environmental standards (such as China, Russia, the United States, EU countries, India and other places with strict emission requirements).

Environmental exhuast gas treatment system of pyrolysis machine

Environmental exhuast gas treatment system of pyrolysis machine

Therefore, the core advantages of the operation of pyrolysis machine, such as resource utilization and low pollution, all rely on oxygen-free or anaerobic conditions.

Henan DOING's pyrolysis machine uses anaerobic pyrolysis technology to ensure safe and efficient treatment of various organic wastes and resource conversion. It can achieve a stable oxygen-free environment and has the following characteristics:

A. Strong sealing: a variety of sealing technologies, including high-temperature corrosion-resistant sealing materials, a strict feeding system, a positive and negative pressure system, and a tight pyrolysis reactor design.

DOING pyrolysis reactor fabrication factory

DOING pyrolysis reactor fabrication factory

B. Temperature control system: an efficient temperature control system can ensure that the temperature inside the reactor remains uniform and stable under high temperature conditions, and can monitor temperature changes in real time and make adjustments.

C. Gas recovery and purification system: pyrolysis machine needs to be equipped with an efficient gas recovery and purification system to achieve maximum energy utilization on the basis of complying with national environmental protection standards.

contact us

CONTACT US