WhatsApp

WhatsApp

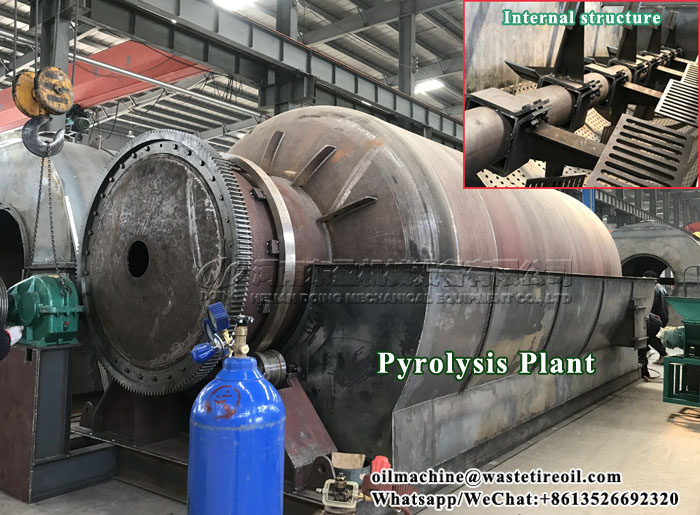

The pyrolysis reactor is an important part of the pyrolysis plant. It is mainly used to load waste tires and plastics. When the pyrolysis reactor is continuously heated, the tires and plastics will continue to pyrolyze out oil gas. After the oil gas is pyrolyzed out, carbon black and steel wire will remain in the pyrolysis reactor. As we all know, pyrolysis plant is an environmentally friendly machine that pyrolysis waste tires and plastics into oil gas, non-condensable gas and carbon black by high temperature heating, and converts waste into reusable resources. Not only solve the problem of environmental pollution, but also create renewable resources for society. Its main function is achieved through the pyrolysis reactor.

Pyrolysis plant and the final products

Pyrolysis plant and the final products

According to the handling capacity, DOING pyrolysis reactor has 3 types: 10 tons, 12 tons and 15 tons per day.

According to the size of the tank, they are :2.6m by 6.6m, 2.8m by 6.6m and 2.8m by 7.5m.

According to the structure, pyrolysis reactor can be divided into: insulation system, tank heating system, transmission system, cold air system and slag discharge system.

Outside the outsourcing is the insulation system of pyrolysis reactor. Inside the insulation system is the tank heating system. A transmission system is arranged at the inlet and outlet of the pyrolysis tank. The left and right sides of the insulation system are respectively equipped with natural air inlet and air outlet for the cold air system.

Then how exactly does the pyrolysis reactor work?

The main part of pyrolysis reactor

The main part of pyrolysis reactor

1. First, when the pyrolysis reactor finishes feeding, in order to ensure uniform heating of the tank, the rotating system will go through the 4kw reducer with a speed ratio of 48.57 to evenly heat the tank of the pyrolysis reactor at a speed of 150 seconds/turn.

With the heating process, the tank of the pyrolysis reactor will expand and contract when heated. The tank can be effectively pushed to the direction of the feed inlet through the stable tank to avoid the phenomenon of air leakage in the expansion of the rear end and the connection of the buffer tank, thus increasing the safety of the pyrolysis reactor.

2. With the increase of temperature, the raw materials in the reactor undergo pyrolysis reaction. When the temperature reaches about 200 ℃, if the temperature rises too fast, shut down the two-stage burner and the temperature in the pyrolysis reactor will rise slowly.

3. When the temperature in the pyrolysis reactor reaches 200-300 ℃, this is the best oil production stage, characterized by the maximum amount of oil produced, the fastest temperature rise, the duration of about 4 hours, in this stage, the temperature of the pyrolysis reactor is very important to maintain.

4. When less oil is produced, the temperature in the pyrolysis reactor increases to between 300 and 340 degrees Celsius until no oil is produced. This stage is the refining of the oil remaining in the steel wire.

5. When all the oil gas is refining finished, pyrolysis reactor need to be cooled down. The way is to open the bottom right hand corner on cooling the exhaust wind and fan inlet valve for cooling, through 15 kw airflow is 8400-15200 m3 / h induced draft fan sucked the air inlet cooling air into the pyrolysis reactor, the high temperature air discharge within the pyrolysis reactor at the same time. The pyrolysis reactor will be in 4-5 hours rapid cooling with this heat exchange. This operation for pyrolysis reactor improves the work efficiency and save production time. Above are the main works of the pyrolysis reactor.

Pyrolysis plant installed all over the world

Pyrolysis plant installed all over the world

Some people may think these operations complicated, but don't worry about that at all. When our engineers go to your side for installing the pyrolysis plant, they will carefully teach your workers to operate the pyrolysis reactor, and we have after-sales operation manuals, and the operation and maintenance of the pyrolysis plant have very detailed instructions. Look, the picture above is the DOING engineer to guide the installation of the pyrolysis plant project aroud the world.

If you want to know more about our pyrolysis reactor, you can contact us directly.

contact us

CONTACT US