WhatsApp

WhatsApp

Using waste plastic pyrolysis plant to pyrolyze the waste plastic is an effective way to solve "white pollution", and it is also one of the current research hotspot in environmental protection at home and abroad. The waste plastic can be turned into fuel oil, carbon black and tail gas by processing of pyrolysis plant, which can bring high economic benefits to investors.

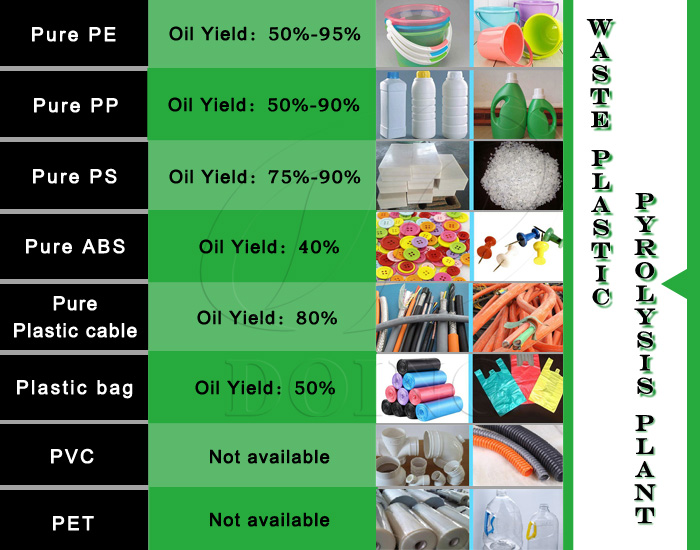

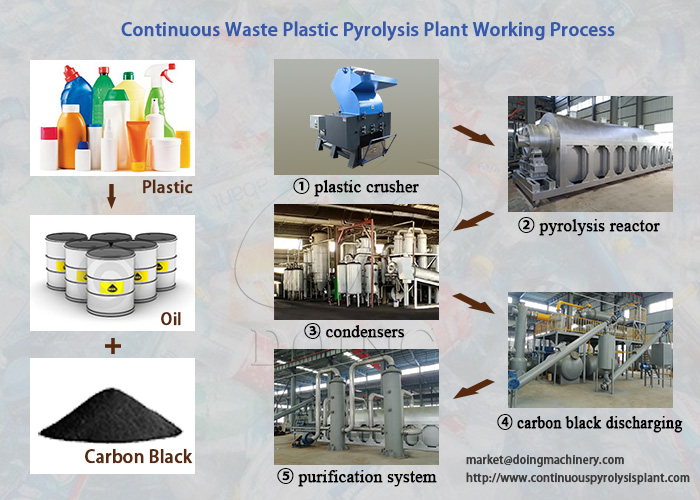

Different types of waste plastics produce different proportions of waste plastic pyrolysis products. But the detailed waste plastic pyrolysis process is same, it mainly includes five steps: waste plastic feeding, plastic pyrolysis, oil gas cooling, tail gas and fume purification, carbon black discharging.

Different types of waste plastics produce different oil yield

Different types of waste plastics produce different oil yield

Step 1: Feed the plastic to the reactor of waste plastic pyrolysis plant.

Step 2: The waste plastic will be pyrolyzed by reactor under high temperature and oxygen-free conditions, and then oil gas will generate after reaching a certain temperature.

Step 3: The generated oil gas will buffer in the buffer tank first and then enter the condensing system for cooling into fuel oil.

Step 4: After passing through the condensing system, the remaining uncondensable combustible gas can recycled to heat the reactor after being processed by the tail gas purification system; after the flue gas generated during the heating process of the reactor enters the desulfurization tower for purification treatment, it can be discharged into the atmosphere.

Step 5: After the reactor is cooled, the carbon black produced by waste plastic pyrolysis can be discharged through the underground sealed transfer system.

The process of waste plastic pyrolysis plant

The process of waste plastic pyrolysis plant

After above waste plastic pyrolysis process, the produced fuel oil can be used for boiler heating, heavy oil generator, or be refined into diesel; the carbon black can be made into pellets for burning or heating; the uncondensable gas can be recycled for heating the reactor to save the operation cost. So we can say that the pyrolysis of waste plastics business has fully turned waste plastics into treasure.

contact us

CONTACT US