WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

As we all know, with the development of the petrochemical industry, a large amount of oil sludge is produced every year, which has poor fluidity, high viscosity and high colloidal asphaltene content. The common treatment methods are solidification landfill method, extraction method, incineration method, etc., but on the one hand, these methods will waste the precious energy contained in the oil sludge, and on the other hand, they will cause serious pollution to the soil, water, air, etc.

While oil sludge pyrolysis plants can avoid these problems very well and recycle oil sludge to valuable resources, generating gerat economic and environmental benefits. Its working principle is that oil sludge is incinerated to a certain temperature under anaerobic conditions, so that hydrocarbons are separated in complex hydration pyrolysis reactions, then the oil gas will be condensed and recovered to fuel oil environmentally friendly.

The following is the working process of oil sludge treatment with pyrolysis plant:

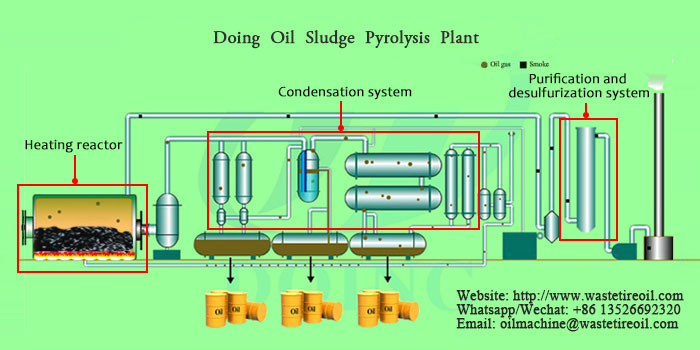

Working process of DOING oil sludge pyrolysis plant

Working process of DOING oil sludge pyrolysis plant

1. Feeding and heating: Put the oil sludge to the oil sludge pyrolysis plant and heat the reactor to a certain temperature between 280°C-320°C, then a large amount of oil gas will be generated.

2. Cooling: After the oil gas is generated, it passes through the buffer tank to buffer the flow of oil and gas, and the buffered oil gas is cooled by our three-step cooling system. Then the oil gas will be fully recovered to fuel oil. Our cooling system adopts shell and tube condensers, water only goes through between the shell and inner tube for cooling the oil gas going through the inner tube, which avoids waste water pollution.

3. Waste gas purification: Apart from the oil gas, there are also some uncondensable gas being produced. After being treated by the tail gas purification system, it can be directly used as fuel to heat the reactor, thereby saving pyrolysis plant operating costs.

Environmental protection system of DOING pyrolysis plant

Environmental protection system of DOING pyrolysis plant

4. Flue gas purification: During the pyrolysis process of oil sludge, flue gas will be produced, which will contain a small amount of harmful gases such as sulfur dioxide, etc., so DOING equips a desulfurization tower to purify the flue gas. After secondary purification, the gas can reach the environmental protection emission standards in various regions.

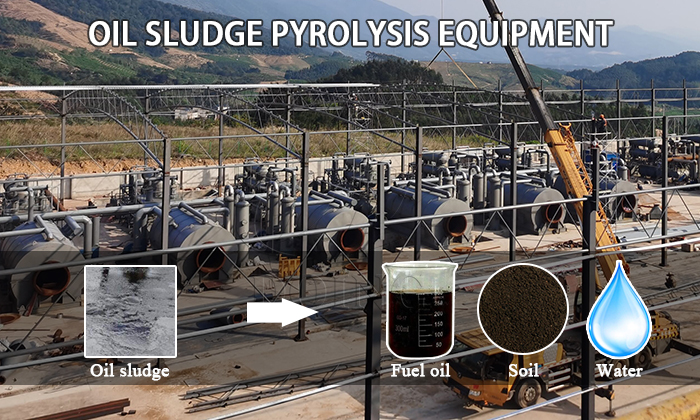

5. Products collection: The products after pyrolysis of oil sludge include fuel oil, combustible gas, water and solid matter. The oil enters the oil tank for storage; the combustible gas is directly heated for use, and the water and solid matter are collected and processed uniformly.

After the above process, we can recycle waste oil sludge to good quality fuel oil with the oil sludge pyrolysis plant, which can be used in cement factory, boiler heating and heavy oil machinery. That's why pyrolysis plant become a popular oil sludge treatment way.

Final products of DOING oil sludge pyrolysis plant

Final products of DOING oil sludge pyrolysis plant

DOING Company has a complete quality management system, not only equipped with a variety of testing equipment but also backed by high technical force, which provides a reliable guarantee for product quality. In addition, DOING also provide other types for your reference, factory price and good performance! If you have an interest in pyrolysis plants, welcome to contact us, our sales manager will provide you with suitable schemes based on your situation.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.