WhatsApp

WhatsApp

Coal tar is a byproduct produced in the process of coking coal, which is viscous and gelatinous, and is difficult to degrade and break down. Coal tar residue is potentially harmful to the environment. Therefore, the treatment and disposal of coal tar requires appropriate measures to reduce adverse environmental and human health effects. So how can coal tar residue be disposed of?

Today we will introduce a better solution for you- coal tar pyrolysis plant, which can obtain fuel oil, semi-solid residues and combustible gas of coal tar distillation in coal tar pyrolysis plant.

1. What is the coal tar pyrolysis plant?

A coal tar pyrolysis plant is a facility or system designed to convert coal tar into various valuable products through the process of pyrolysis. Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen, leading to the breakdown of complex organic substances into simpler compounds.

DOING coal tar pyrolysis plant for sale

DOING coal tar pyrolysis plant for sale

2. The working process of coal tar pyrolysis plant

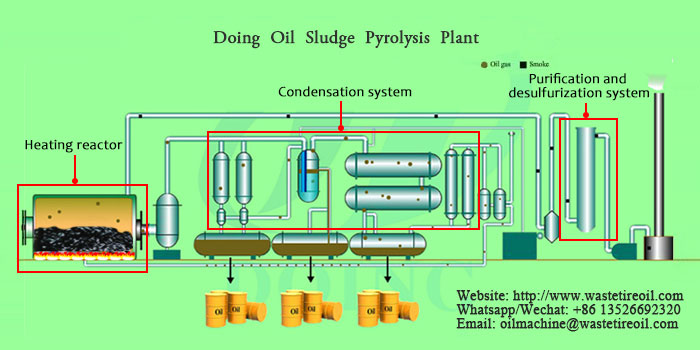

The coal tar residue is fed into the pyrolysis reactor through a special feeding system, and the coal tar residue pyrolysis reaction occurs at the pyrolysis temperature. Then its macromolecular structure breaks down and oil gas is produced. After entering the cooling system, the oil and gas can be fully cooled to liquid oil and stored in oil storage tanks, with the resulting non-condensate gas recovered and used as fuel for the pyrolysis furnace.

Working process of DOING coal tar pyrolysis plant

Working process of DOING coal tar pyrolysis plant

3. What useful products can we convert coal tar into with the coal tar pyrolysis plant?

It can be seen from the above pyrolysis process that with the coal tar pyrolysis plant we can obtain several useful products:

1) Fuel oil similar to diesel, its calorific value is very high, up to more than 10,000 calories per kilogram;

2) Semi-solid residues similar to asphalt can be sold directly in the market;

DOING coal tar pyrolysis plant for sale

DOING coal tar pyrolysis plant for sale

3) Non-condensable tail gas is directly returned to the furnace for combustion.

So you can see that this coal tar pyrolysis plant basically has a 100 percent recycling rate and no waste. So which manufacturer of coal tar pyrolysis plant is better?

Henan DOING Company will be your best cooperation partner.

1. DOING company has over 13 years experience in manufacturing pyrolysis plants. And due to the special state of coal tar, our engineer team also made special designs for the coal tar pyrolysis, such as the unique manufacturing raw materials and configurations to avoid sticking walls; higher pyrolysis efficiency to fully recycle coal tar; exclusively developed patented device-vacuum device to enhance working safety; provide customization services to dispose of various states of coal tar; providing some environmentally friendly equipment to meet the standards of some countries that are very strict about emissions, etc.

Environmental protection systems of DOING pyrolysis plant

Environmental protection systems of DOING pyrolysis plant

2. DOING has cooperated with many customers on our coal tar pyrolysis plants and received good feedback. For example, we just cooperated with a Chinese customer on our coal tar pyrolysis plant and now the coal tar pyrolysis plant has been put into operation successfully. (Recommended reading: 8 sets of 10TPD oil sludge pyrolysis machines installed in Shaanxi Province, China!)

All in all, if you have coal tar to dispose of, just feel free to contact us, we can provide the customization services based on your actual demands. And apart from the coal tar, our pyrolysis plant can also recycle other wastes, such as scrap tyres, mixed plastics, oil sludge, aluminum plastics, etc., so looking forward to cooperating with you.

contact us

CONTACT US