WhatsApp

WhatsApp

In the waste tire recycling industry, tire pyrolysis reactor plays a crucial role. The cooling speed of the tire pyrolysis reactor not only affects the production efficiency, but also the life of the equipment, the quality of the final product and the safety of the operators. The following are several effective methods and steps proposed by DOING to increase the cooling speed.

1.Stop heating

After the tire pyrolysis reactor is completed, all heat sources should be turned off first, including but not limited to gas torches or external heating systems, to cut off the direct heat supply to the tire pyrolysis reactor. Combined with the vacuum negative pressure device of DOING patented equipment, it can not only accelerate the cooling rate, but also ensure the safety of the entire operation.

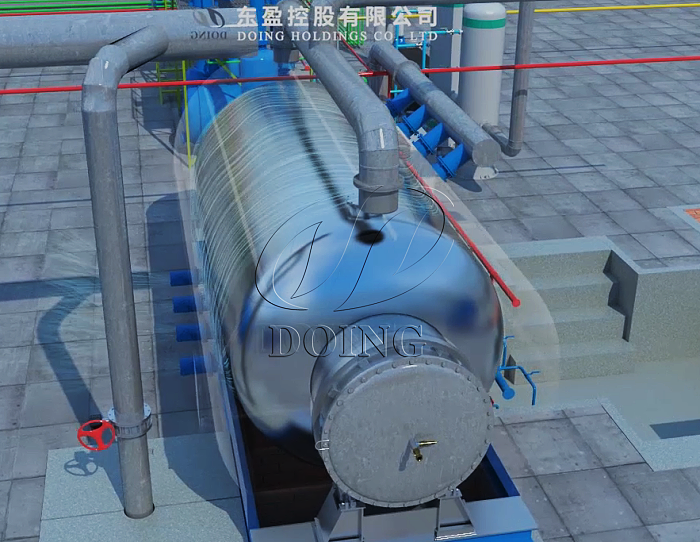

DOING patented safe equipment

DOING patented safe equipment

2.Control the temperature and cooling speed

The temperature cannot be suddenly reduced significantly under high temperature to avoid stress deformation or pyrolysis of the metal structure of the tire pyrolysis reactor due to thermal expansion and contraction. Usually when the temperature of the main tire pyrolysis reactor rises to above 450℃, it is necessary to gradually reduce the temperature and keep the air bag temperature gauge down to between 120℃-140℃ to ensure that the cooling process is smooth and controllable.

3.Start natural cooling and auxiliary cooling system

In addition to natural cooling, the auxiliary cooling system-cold air system can be started to quickly cool down the tire pyrolysis reactor. Open the induced draft fan and 4 air inlet valves, the induced draft fan will extract the hot air in the tire pyrolysis reactor, and the cold air will come in through the air inlet, and the effect of rapid cooling and cooling the tire pyrolysis reactor can be achieved through the exchange of hot and cold air.

Start natural cooling system

Start natural cooling system

At the same time, the insulation performance of the tire pyrolysis reactor body itself can be used to allow it to dissipate heat naturally. The insulation materials in the tire pyrolysis reactor external insulation system manufactured by DOING are divided into inner insulation materials and outer insulation materials, which can play the role of insulation, heat preservation, sound absorption and noise reduction.

4.Discharge of residual oil and residual gas

When the gas bag is cooled to 80℃-90℃, the residual oil is discharged in time, and the relevant valves are opened to empty the remaining gas to further reduce the internal heat.

5.Monitor temperature and pressure

The changes of temperature and pressure instruments should be closely monitored throughout the tire pyrolysis process to ensure that no abnormal conditions occur during the cooling process. If necessary, a phased cooling and interval observation method should be adopted to ensure safety.

DOING tire to fuel pyrolysis machine process

DOING tire to fuel pyrolysis machine process

6.Professional maintenance and inspection

After completing the rapid and safe cooling of the tire pyrolysis reactor, and confirming that the tire pyrolysis reactor temperature has dropped to normal temperature, professionals can be arranged to carry out equipment inspection and necessary maintenance work to ensure that the equipment is in good condition before the next round of pyrolysis operations.

By implementing these optimized cooling strategies, DOING waste tire recycling pyrolysis machines not only enhance productivity but also ensure long-term operational reliability and environmental compliance. If you want more efficient pyrolysis equipment, DOING also provides semi-continuous and fully continuous pyrolysis equipment, which can achieve high-temperature slag discharge. No matter what questions you have about building a tire pyrolysis plant, DOING can give you the perfect answer. Please feel free to contact us.

contact us

CONTACT US