WhatsApp

WhatsApp

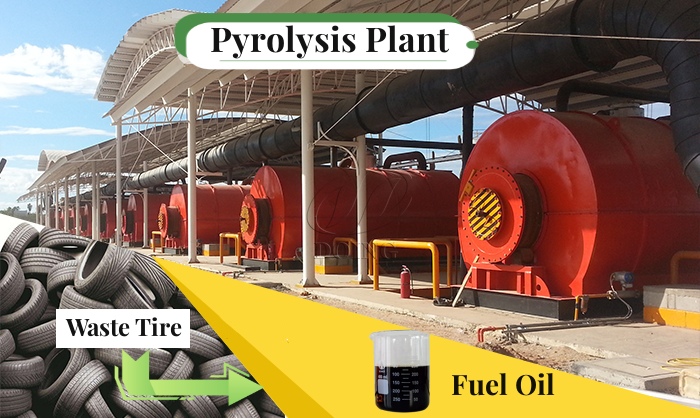

Waste tyre pyrolysis machine uses pyrolysis technology to convert waste tyres into pyrolysis oil, carbon black, steel wire and combustible gas. This can not only solve the environmental problems caused by the accumulation of waste tyres, but also turn the waste into treasure. With the development of economy, the production of waste tyres is also increasing year by year, and the waste tyre pyrolysis machine will undoubtedly become a new trend of tyre waste management.

DOING waste tyre pyrolysis machine project

DOING waste tyre pyrolysis machine project

With more than ten years of experience in waste tyre pyrolysis industry, Doing Group not only has an independent technical research and development team, but also has a professional manufacturing team, so our products are very competitive.

| Advantages | Explanations |

| High quality | The reactor is designed with 16mm boiler steel plate and standard curved pressure head, which can withstand high temperature and pressure and is not easy to produce cracks. |

| High efficiency | It is no need for pretreatment processes such as cleaning, crushing, wire extraction, etc., and the whole tires are directly fed into the inside of the pyrolysis reactor under the action of belt conveyor, which is highly automated, safe, convenient and time-saving. |

| High oil yield | The four-stage condensing system, including buffer, horizontal condenser, vertical condenser and condensing tower, can make the oil gas fully cooled and the oil output rate is high. |

| Safety | It is equipped with safety devices such as safety valve, electric pressure gauge, temperature gauge and deviation alarm which greatly improve the safety of the machine. |

| Environmental protection | It is equipped with tail gas purification device, smoke purification device and carbon black collection device, which can make the whole pyrolysis process meet the environmental protection standard. |

There are many types of waste tyres, mainly containing: Different waste tyres have different oil yield rates. Usually the oil yield of the waste tyres with higher rubber content and lighter wear is higher; and vice versa. So try to choose the raw materials with high oil yield so as to increase the profit.

| Raw materials | images | oil yield |

| Engineering tyre |  | 45% |

| Car or bicycle tyre |  | 40% |

| Rubber cable leather or sole |  | 35% |

| Waste chemical fiber carpet |  | 30% |

Doing group has designed different capacities of waste tyre pyrolysis machines to meet the different requirements of our customers. Below are the specific parameters of the machines for your reference. In addition, we can also customize the waste tyre pyrolysis machine according to your situation.

| Technical Parameters of Waste Tyre Pyrolysis Machine | |||

| Items | Contents | ||

| Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| Day Capacity | 6 ton | 8 ton | 10 ton |

| Oil yield | 2.7-3.3 ton | 3.6 -4.4 ton | 4.5 -5.5 ton |

| Structural form | Horizontal rotation | ||

| Operating pressure | Normal | ||

| Material of pyrolysis reactor | Q245R | ||

| Thickness of pyrolysis reactor | 16mm | ||

| Rotate speed of pyrolysis reactor | 0.4turn/minute | ||

| Size of reactor(D×L) | 2200*6000-2800*6600 | ||

| Total power | 19KW | ||

| Mode of cooling | Water cooling | ||

| Cooling area of condenser | 100sqm | ||

| Kind of transmission | Internal gear drive | ||

| Noise dB(A) | ≤85 | ||

| Weight | 27T-35T | ||

| Working form | Intermittent operation | ||

| Delivery time | 20days | ||

| Land area | 35m*15m | ||

| Labor | 3-4 workers | ||

| Density of oil | 0.91g/cm3 | ||

| Calorific value | 44.32MJ/KG | ||

Fuel oil can be used directly for industrial or boiler heating, but also can be refined into diesel for power plants, agricultural machinery, etc.; Carbon black can be balled and burned for industrial heating, its combustion calorific value is equivalent to coal, can be used directly instead of coal, wood, gas, etc. It can also be refined into different standards for paint pigments, rubber products and other additives; Steel wires can be sold to waste recycling stations, and also directly sold to steel smelter, re-smelting.

| Final products | Images | Applications |

| Fuel Oil |  | It can be widely used as fuel in industrial plants, such as glass plants, cement plants, power plants, etc. For more valuable and widely used fuel oil, it can also be further refined into diesel by our tyre oil to diesel distillation plant. |

| Carbon Black |  | It can be sold directly or used as a raw material or major component in many industries, such as making pigments, shoe soles, tyres, etc. |

| Steel wire |  | It can be sold directly or reprocessed. |

| Combustible gas |  | It can be recycled to furnace to heat reactor instead of coal/wood/oil/natural gas. |

contact us

CONTACT US