Which company supplies continuous pyrolysis machines for sale in India?

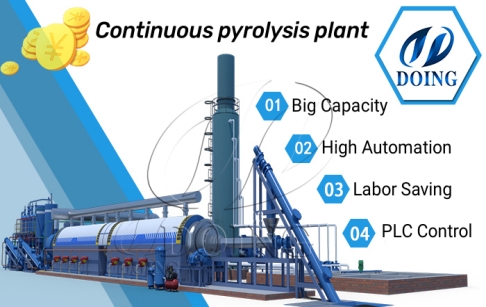

January 9,2024DOING Group supplies continuous pyrolysis machines in India, which has several years' experience in manufacturing and helping our customers set up continuous pyrolysis machine projects.

English

English Русский

Русский Français

Français Español

Español Tiếng Việt

Tiếng Việt 한국인

한국인 日本語

日本語 แบบไทยไทย

แบบไทยไทย Indonesia

Indonesia Deutsch

Deutsch Português

Português عربي

عربي हिन्दी

हिन्दी Українська

Українська Türkçe

Türkçe Malaysia

Malaysia Italiano

Italiano