WhatsApp

WhatsApp

How much waste tire pyrolysis plant costs is affected by various factors such as the models, configurations, types, and manufacturing cost of the equipment, etc. And the fluctuation of waste tire pyrolysis plant cost is relatively large. Here, we can learn some knowledge first to help us to get the detailed cost of waste tire pyrolysis plant.

1. Equipment model: The price of different types of waste tire pyrolysis plant is also different. The daily processing capacity is the key factor affecting the model. The larger the daily processing capacity, the more expensive the price.

Fully continuous type pyrolysis plant and batch type pyrolysis plant

Fully continuous type pyrolysis plant and batch type pyrolysis plant

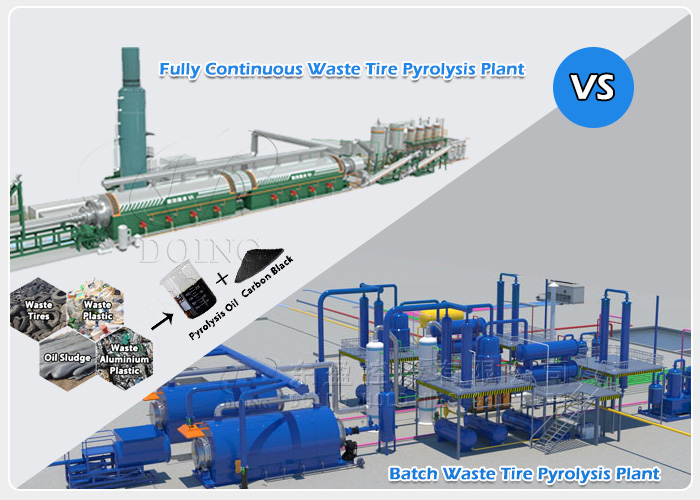

2. Equipment type: There are mainly two types of waste tires pyrolysis plant that Doing Company can customize for customers. One is batch(intermittent) waste tire pyrolysis plant, which cracks waste tires in batches and is very cost-effective. The other is the fully continuous waste tire pyrolysis plant, which can work continuously for 24 hours and is suitable for users with large tire processing capacity. The pyrolysis efficiency is extremely high and the benefit is relatively high.

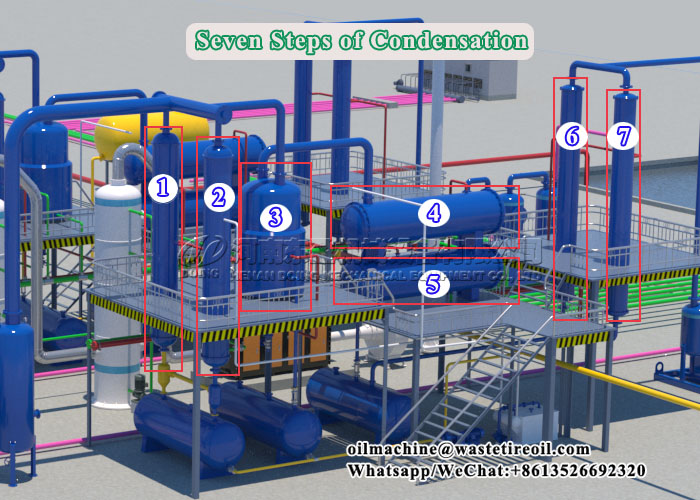

3. Equipment configuration: In order to help customers achieve maximum benefits, our sales managers will provide different solutions based on the specific needs of customers and local policy needs.

For example, different countries have different degrees of environmental protection requirements, and we can provide different environmental protection device configurations. The higher the configuration, the higher the degree of environmental protection that the equipment can meet, and the higher the cost of waste tire pyrolysis plant.

Cooling system

Cooling system

In terms of equipment configuration, DOING has also launched a "modular" combination of reactors for waste tire pyrolysis plant, which can flexibly adjust the scale according to the size of the production capacity. It just needs to increase or decrease the number of pyrolysis reactors in series, which greatly saves equipment investment cost and is more convenient for operation.

4. Manufacturing cost: Waste tire pyrolysis plant is mainly made of steel, and the fluctuation of steel price directly affects waste tire pyrolysis plant cost. In different periods, different demands and different exchange rates will affect the price of steel, resulting in different prices of steel ordered by manufacturers and different equipment costs, so the price of waste tire pyrolysis plant will also be different.

Pyrolysis reactor

Pyrolysis reactor

5. Equipment manufacturers: Different waste tire pyrolysis plant manufacturers will also have differences in equipment production process, raw material selection, etc., so there will naturally be differences in quotations. The steel selected by Henan Doing Company is the steel for boilers, which has welding resistance, high strength, good performance and long service life. Our waste tire pyrolysis plants have won a number of certificates and reputation with advanced technology, such as patent certificates, ISO, SGS, CE, etc., helping customers achieve clean, environmentally friendly and safe production.

The above is a specific introduction to what factors will affect the waste tire pyrolysis plant cost. Welcome to contact Doing Company, our sales manager will provide you with a specific quotation based on your needs.

contact us

CONTACT US